Stretching conductive liquid metal particle based conductive ink and preparation method and application thereof

A technology of conductive ink and liquid metal, applied in the direction of application, ink, metal pattern materials, etc., can solve the problems of low utilization rate of liquid metal particles, rupture of liquid metal particles, low production efficiency, etc., and achieve high utilization rate, low cost, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

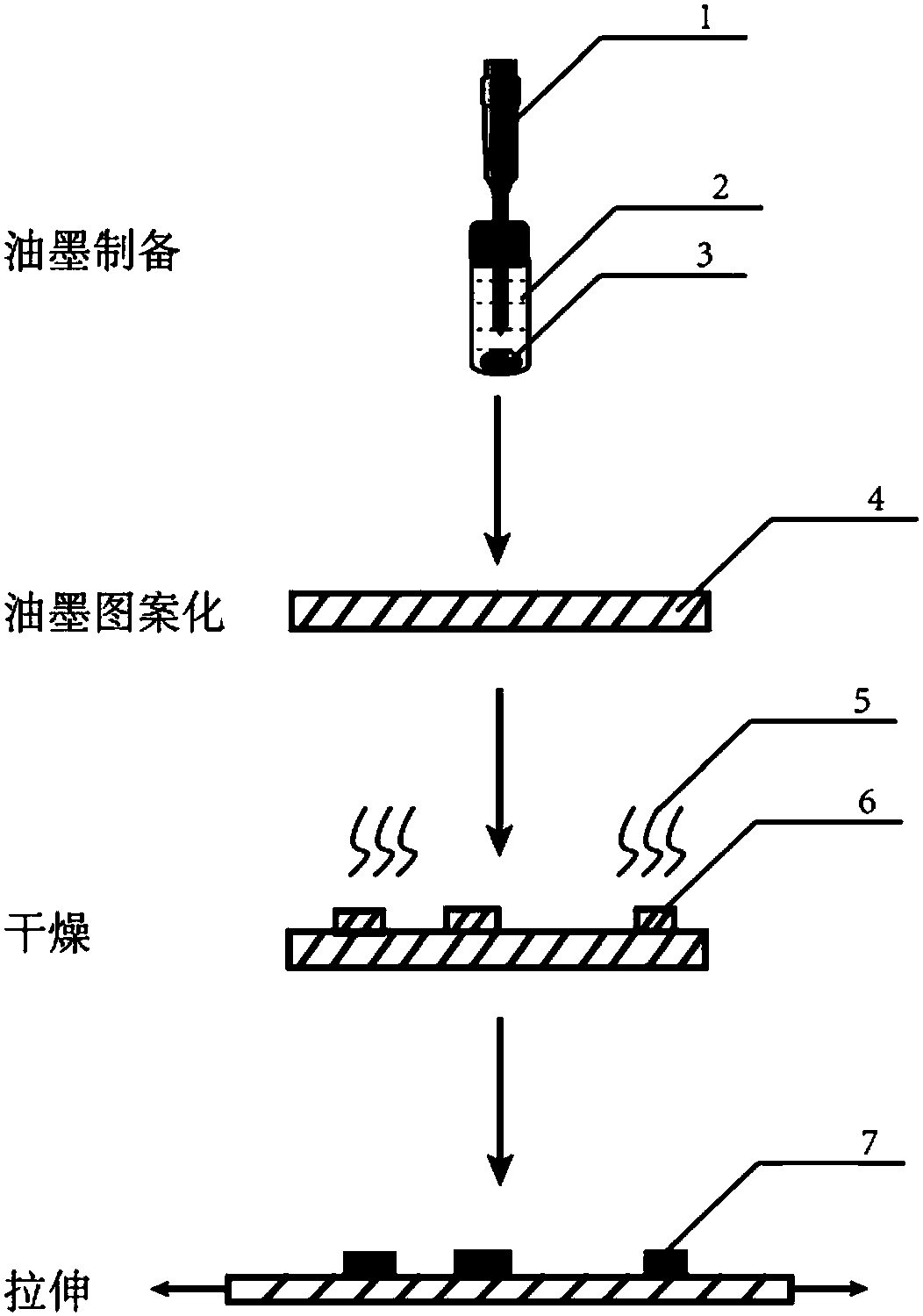

[0066] This example is used to illustrate the liquid metal conductive ink and the use of the ink to prepare flexible conductive circuits.

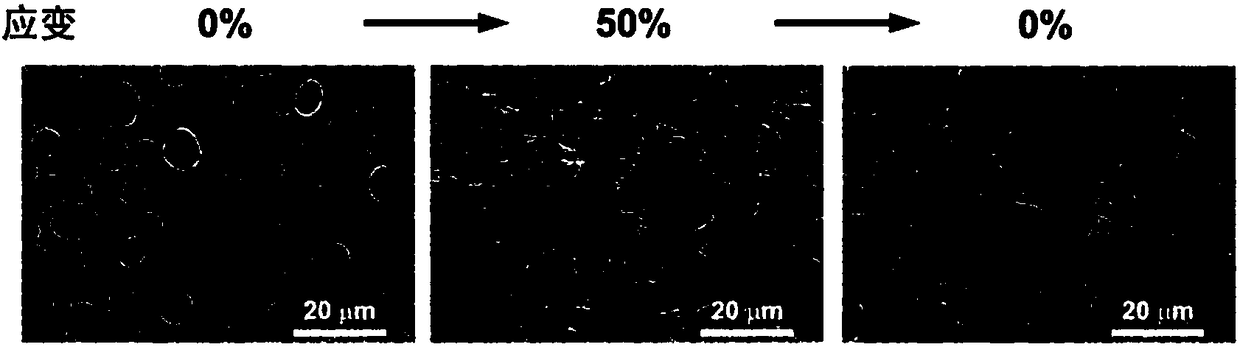

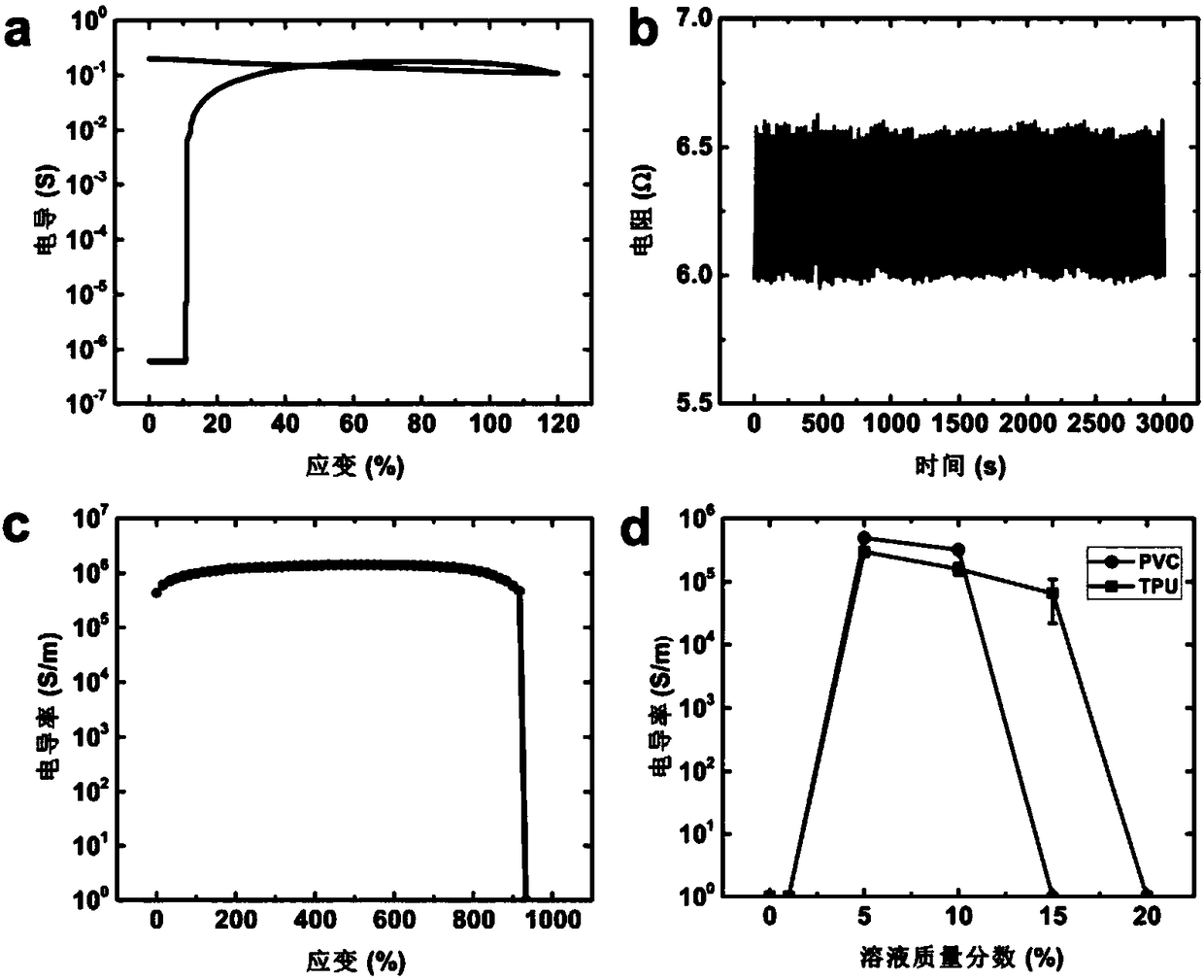

[0067]Add 0.5g of polyvinylpyrrolidone into 10mL of n-decyl alcohol and stir for 6h to fully dissolve. After polyvinylpyrrolidone (PVP) was fully dissolved, 1 ml of the solution was placed in a plastic tube, and 3 g of liquid indium gallium eutectic alloy (Ga75.5%wt In 24.5%wt) was added at the same time. Using an ultrasonic cell breaker to sonicate for 60s at an amplitude of 30%, the metal is dispersed into numerous micronano-sized small particles, thereby obtaining a gray liquid metal ink. The core of the small particles is liquid metal, and the outside is covered by a thin oxide film. Pouring evenly mixed PDMS (mass ratio, prepolymer: curing agent = 10:1) on a glass plate, and curing in an oven at 80 degrees Celsius for 2 hours, after curing, peel off the PDMS from the glass plate to obtain PDMS. film. Use a manual screen printing st...

Embodiment 2

[0069] This example is used to illustrate the liquid metal conductive ink and the flexible and stretchable conductive circuit prepared using the ink.

[0070] Put 1g of polyvinylpyrrolidone, 5uL of fluorocarbon surfactant and 0.1g of chitosan in 10mL of tetrahydrofuran, and stir for 6 hours to fully dissolve. After the polyvinylpyrrolidone was fully dissolved, 1 mL of the solution was placed in a plastic tube, and 2 g of liquid indium gallium tin alloy (In 22%wt Ga 68%wt Sn 10%wt) was added at the same time. Ultrasonic cell breaker was used to sonicate at 30% amplitude for 30 minutes to obtain a gray liquid metal suspension, and the metal was dispersed into small particles of micro-nano size. Spread the aqueous polyurethane solution on a glass plate and place it at room temperature to dry for 12 hours to form a film. After the polyurethane film is formed, it is peeled off from the glass plate to obtain a polyurethane film. The prepared conductive ink was added to a piezoelect...

Embodiment 3

[0072] This example is used to illustrate the liquid metal conductive ink and the flexible and stretchable conductive circuit prepared using the ink.

[0073] Put 0.5g of thermoplastic polyurethane and 0.01g of N-(2-hydroxyethyl)dodecylamide into 10mL of N,N-dimethylformamide solution, stir well to dissolve. Take 1 mL of the solution and place it in a plastic tube, and add 2 g of gallium-zinc alloy (Ga95%wt Zn 5%wt) into the solution. The conductive ink was prepared according to the method of Example 1. Since the melting point of the gallium-zinc alloy (37 degrees Celsius) was slightly higher than room temperature, it was heated in an oven at 80 degrees Celsius for 30 minutes before ultrasonication. Thus, a conductive ink is obtained. Mix the components A and B of Ecoflex silica gel in equal quantities, stir well, apply on PET plastic film, and cure at room temperature for 6 hours to obtain Ecoflex silica gel film. Stick the stencil of the desired pattern on the Ecoflex film...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com