Green flocculant for sewage treatment

A sewage treatment and flocculant technology, applied in water/sewage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., can solve problems such as limited molecular weight, high price, loss of flocculation activity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

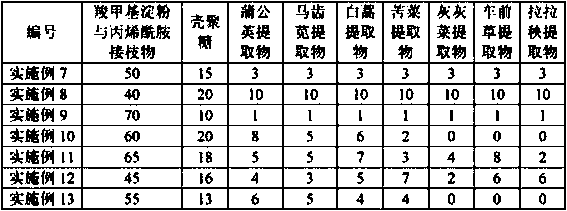

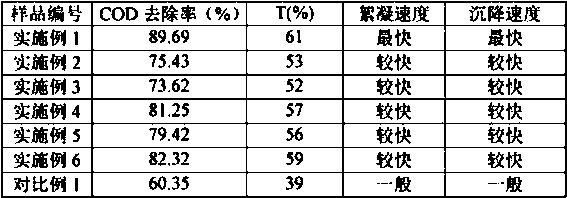

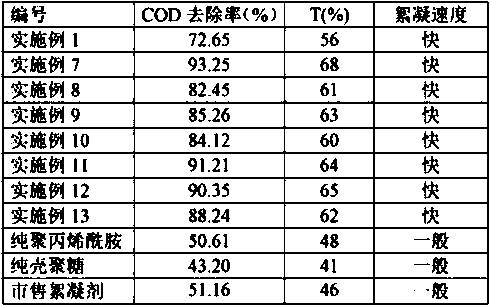

Examples

Embodiment 1

[0050] Preparation of carboxymethyl starch grafted acrylamide copolymer: in parts by weight, add 2 parts of carboxymethyl starch to 70 parts of deionized water, heat to 85° C., and keep stirring under nitrogen protection for gelatinization for 1 hour. Cooling; add the initiator potassium persulfate afterwards, the initiator concentration is 5.5×10 4 mol / L; then add 9 parts of monomeric acrylamide, at 50°C, the reaction time is 4 hours, after the reaction, wash the product with absolute ethanol, and dry the product under reduced pressure to constant weight.

Embodiment 2

[0052] Preparation of carboxymethyl starch grafted acrylamide copolymer: in parts by weight, add 1 part of carboxymethyl starch to 90 parts of deionized water, heat to 90°C, and continuously stir for gelatinization under nitrogen protection for 0.5h , cooling; then add the initiator potassium persulfate, the initiator concentration is 4.25 × 10 4 mol / L; then add 3 parts of monomeric acrylamide, at 45°C, the reaction time is 1 hour, after the reaction, wash the product with absolute ethanol, and dry the product under reduced pressure to constant weight.

Embodiment 3

[0054] Preparation of carboxymethyl starch grafted acrylamide copolymer: in parts by weight, add 2.5 parts of carboxymethyl starch to 80 parts of deionized water, heat to 70°C, and keep stirring under nitrogen protection for 1.5 hours of gelatinization , cooling; then add the initiator potassium persulfate, the initiator concentration is 6.80×10 4 mol / L; then add 5 parts of monomeric acrylamide, at 65°C, the reaction time is 6 hours, after the reaction, wash the product with absolute ethanol, and dry the product under reduced pressure to constant weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com