Bagasse-based mulch film and production method thereof

A base film and bagasse technology, which is applied in botany equipment and methods, plant protection, application, etc., can solve the problems of not being able to improve the soil structure, the effect of heat preservation is not obvious, and the film is brittle, and achieve good market prospects. Ease of industrial production and the effect of improving fertility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

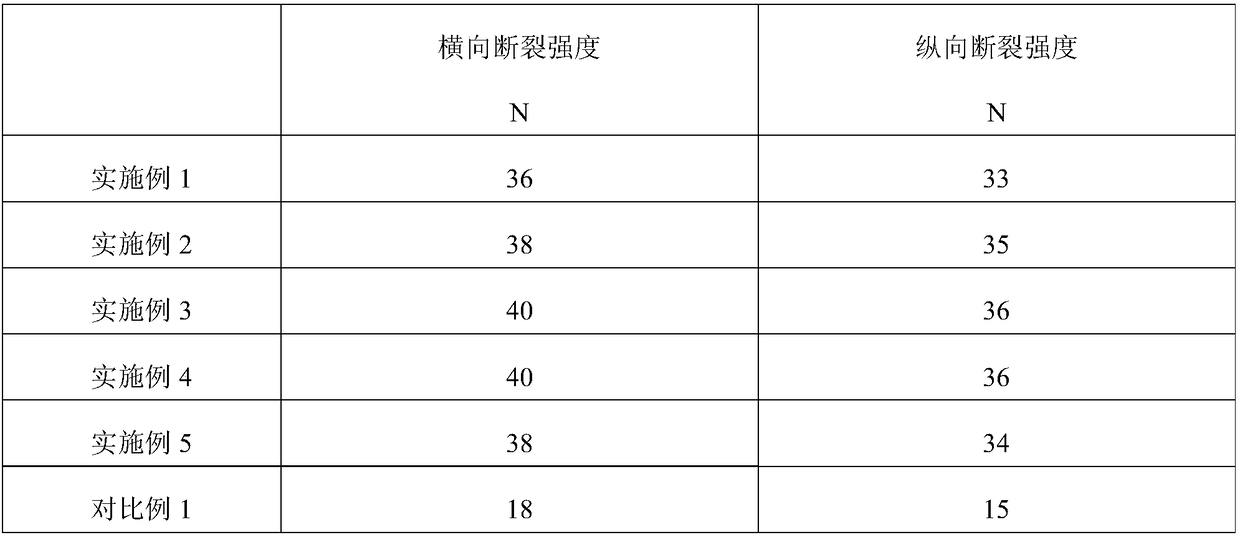

Examples

Embodiment 1

[0040] A bagasse-based film comprises the following components according to weight percentage:

[0041] Bagasse Fiber 50%, Chitin Nano Whiskers 10%, Bagasse Biochar 16.5%, Nano CaCO 3 2%, Nano TiO 2 2%, polyvinyl alcohol 6%, corn starch 6%, glycerin 2%, water retaining agent 3%, sorbitol fatty acid ester 2%, mineral 0.5%.

[0042]The water-retaining agent includes the following components in parts by weight: 15 parts of fly ash, 10 parts of zeolite, 20 parts of polypropylene amine, 20 parts of straw powder, and 30 parts of starch-grafted sodium polyacrylate.

[0043] The minerals are dry powders of deep underground water; the dry powder is prepared by heating the deep underground water at 250° C. for 15 minutes to evaporate the water.

[0044] A preparation method of bagasse base film, comprising the following steps:

[0045] S1. Preparation of bagasse fiber:

[0046] 1) take bagasse, then crush and cross 100 mesh sieves to get bagasse powder;

[0047] 2) Add 0.7% H to th...

Embodiment 2

[0058] A bagasse-based film comprises the following components according to weight percentage:

[0059] Bagasse Fiber 50%, Chitin Nano Whiskers 12%, Bagasse Biochar 14.5%, Nano CaCO 3 2%, Nano TiO 2 2%, polyvinyl alcohol 6%, corn starch 6%, glycerin 2%, water retaining agent 3%, sorbitol fatty acid ester 2%, mineral 0.5%.

[0060] The water-retaining agent includes the following components in parts by weight: 15 parts of fly ash, 10 parts of zeolite, 20 parts of polypropylene amine, 20 parts of straw powder, and 30 parts of starch-grafted sodium polyacrylate.

[0061] The minerals are dry powders of deep underground water; the dry powder is prepared by heating the deep underground water at 250° C. for 15 minutes to evaporate the water.

[0062] The preparation method is the same as in Example 1.

Embodiment 3

[0064] A bagasse-based film comprises the following components according to weight percentage:

[0065] Bagasse Fiber 47%, Chitin Nano Whiskers 15%, Bagasse Biochar 14.5%, Nano CaCO 3 2%, Nano TiO 2 2%, polyvinyl alcohol 6%, corn starch 6%, glycerin 2%, water retaining agent 3%, sorbitol fatty acid ester 2%, mineral 0.5%.

[0066] The water-retaining agent includes the following components in parts by weight: 15 parts of fly ash, 10 parts of zeolite, 20 parts of polypropylene amine, 20 parts of straw powder, and 30 parts of starch-grafted sodium polyacrylate.

[0067] The minerals are dry powders of deep underground water; the dry powder is prepared by heating the deep underground water at 250° C. for 15 minutes to evaporate the water.

[0068] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com