Graphene oxide/polyacrylamide composite filtering thin film as well as preparation and application thereof

A technology of polyacrylamide and composite filtration, applied in the direction of membrane technology, semi-permeable membrane separation, chemical instruments and methods, etc., to achieve the effect of wide application and excellent filtration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Get 50 mg of graphene oxide, dissolve it in 100 ml of distilled water, prepare a graphene oxide aqueous solution with a concentration of 0.5 mg / mL, and disperse it uniformly by ultrasonic;

[0036] (2) Take 5 mg of polyacrylamide with a molecular weight of 1 million, dissolve it in 100 ml of distilled water, prepare a polyacrylamide aqueous solution with a concentration of 0.05 mg / mL, and stir until completely dissolved;

[0037] (3) under stirring conditions, the polyacrylamide aqueous solution of step (2) is added dropwise in the graphene oxide aqueous solution of step (1), stirred for 2 hours and mixed uniformly;

[0038] (4) After mixing evenly, measure 10mL of the graphene oxide / polyacrylamide composite solution sample, use vacuum filtration to form a film, and dry the film naturally to obtain a graphene oxide / polyacrylamide composite film .

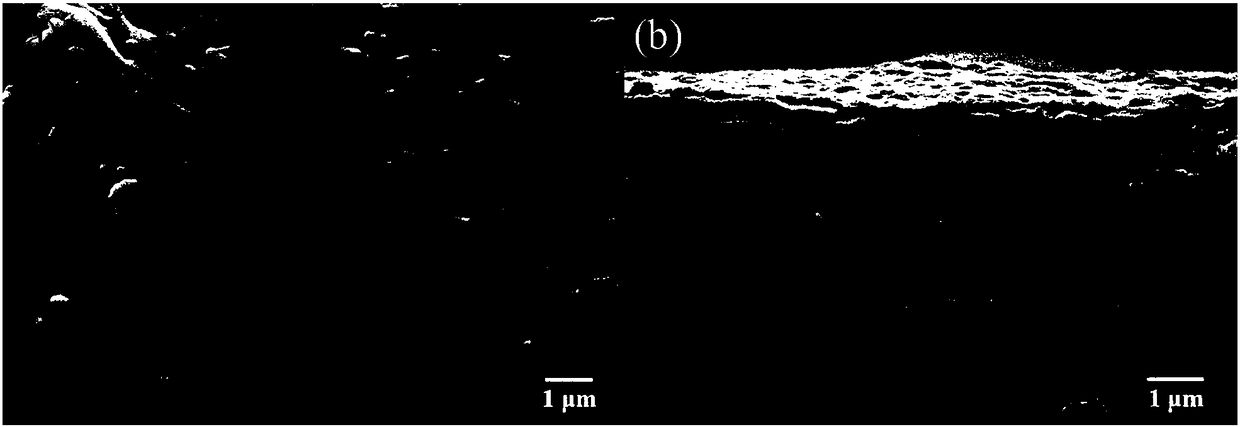

[0039] figure 1 Be the SEM of embodiment 1 composite film, from figure 1 (a) It can be seen that polyacrylamide is u...

Embodiment 2

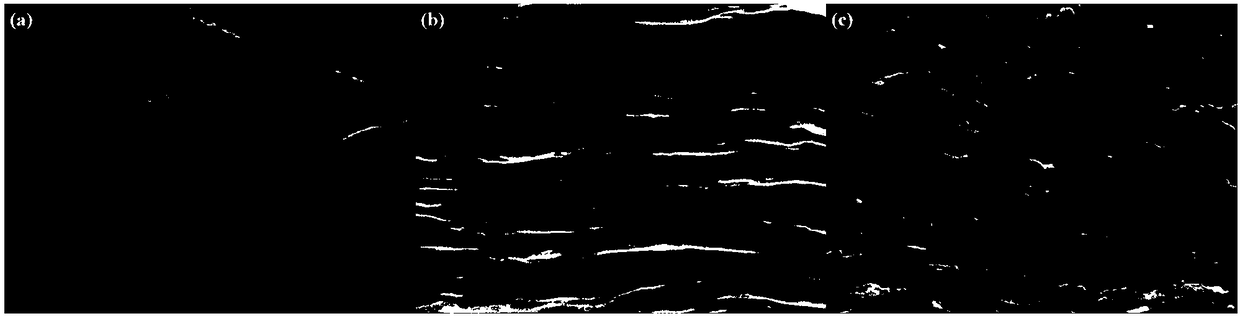

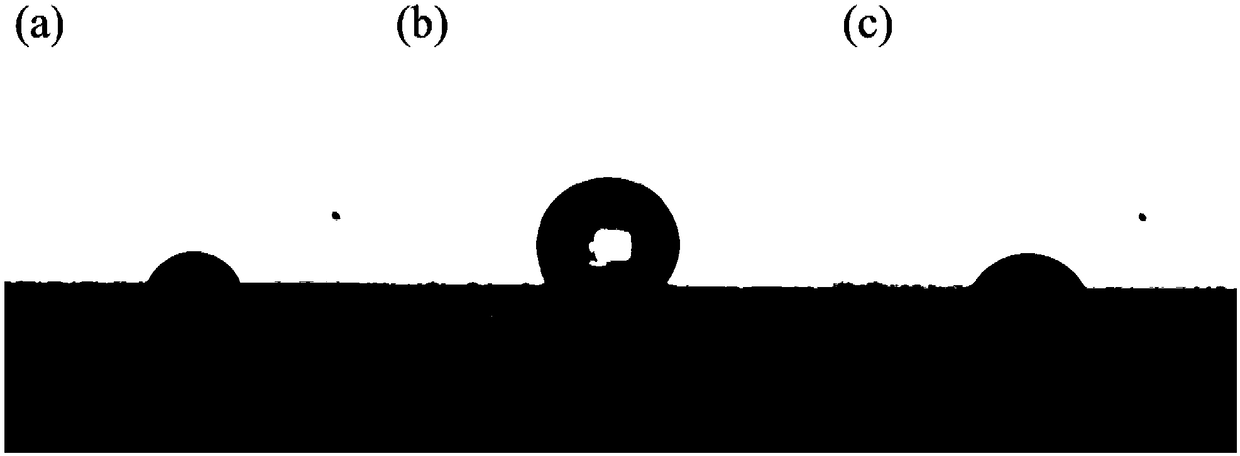

[0043] First, take 25 mg of freeze-dried graphene oxide powder and dissolve it in 100 mL of distilled water, and ultrasonically disperse it to prepare a graphene oxide aqueous solution with a concentration of 0.25 mg / mL; then, transfer the solution to a 100 mL three-necked flask and stir it, Pipette 25 uL of hydrazine hydrate solution with a mass fraction of 35% with a liquid gun, and add it dropwise into a three-necked flask; after stirring evenly, add a solution of ammonia solution with a mass fraction of 28% dropwise to adjust the pH of the reaction system to 10; finally, the reaction system The temperature was raised to 90 °C and reacted at this temperature for 2 hours. Measure 10mL of different solution samples with the same concentration, and use vacuum filtration to form a film. After the film is naturally dried, a graphene oxide filter film, a reduced graphene oxide filter film and a graphene oxide / polypropylene filter film can be obtained. Amide composite filter membr...

Embodiment 3

[0048] (1) Get graphene oxide, be dissolved in distilled water, be mixed with graphene oxide aqueous solution, ultrasonically disperse to uniform;

[0049] (2) Take polyacrylamide, dissolve it in distilled water, prepare polyacrylamide aqueous solution, and stir until completely dissolved;

[0050] (3) under stirring conditions, the polyacrylamide aqueous solution of step (2) is added dropwise in the graphene oxide aqueous solution of step (1), stirred for 2 hours and mixed uniformly;

[0051] (4) After mixing evenly, measure 10mL of the graphene oxide / polyacrylamide composite solution sample, use vacuum filtration to form a film, and dry the film naturally to obtain a graphene oxide / polyacrylamide composite film .

[0052] (5) A reduced graphene oxide solution with a concentration of 0.25 mg / mL and a graphene oxide solution with a concentration of 0.25 mg / mL were prepared again, and an equivalent volume of the solution was vacuum filtered to form a film as a comparison.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com