Restoration method of petroleum-contaminated soil

A technology for oil pollution and restoration methods, which is applied in the restoration of polluted soil, soil conditioning materials, chemical instruments and methods, etc. It can solve the problems of long time for microbial screening and domestication, damage to soil microbial communities, and unsuitability for large-scale use. , to achieve the effect of reducing technical cost, enhancing repair effect and enhancing activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

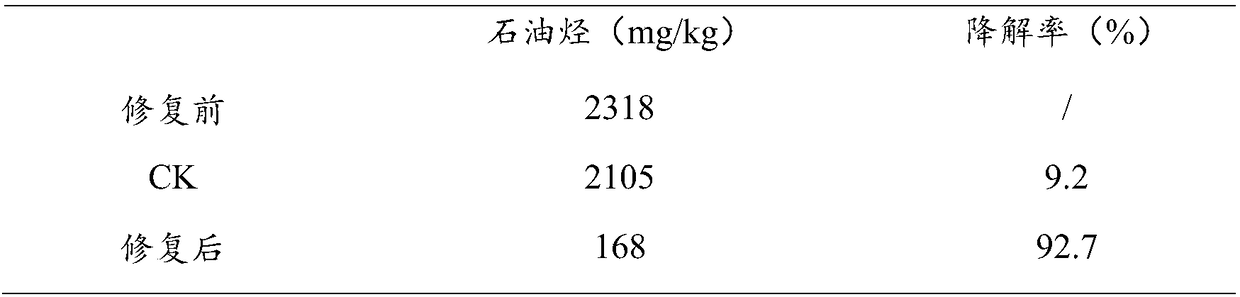

[0033] Firstly, the soil is plowed, and the yeast extract powder aqueous solution is sprayed during the plowing process. Control the spraying amount of the yeast extract powder aqueous solution so that the weight of the yeast extract powder is 8% of the total amount of petroleum hydrocarbons in the oil-contaminated soil. After spraying, the moisture content of the soil was 40%, and the soil was turned and mixed evenly. At an ambient temperature of 25-30°C, cure for 30 days (days). Mix it every 5 days during the maintenance period. At the same time, the soil without yeast extract powder was used as the blank control CK, and the CK and the experimental group were maintained under the same moisture content and temperature conditions. The oil content in the soil was measured before and after remediation, and the test results are shown in Table 1.

[0034] Table 1 Test data before and after soil remediation

[0035]

[0036] The content of petroleum hydrocarbons was reduced ...

Embodiment 2

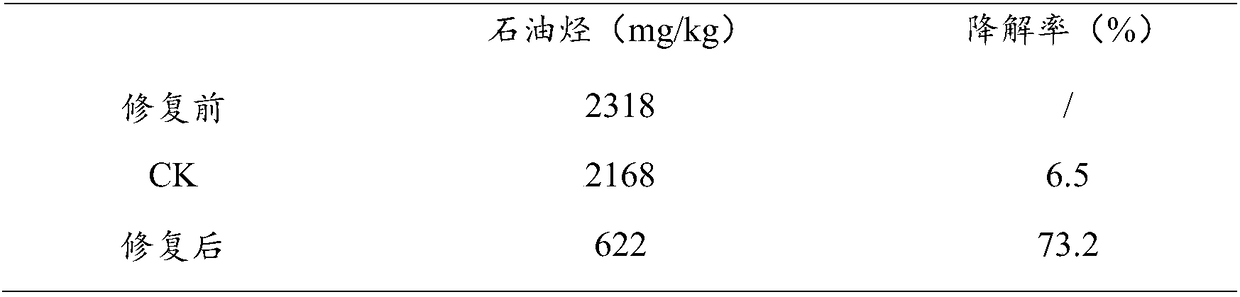

[0038] The oil-contaminated soil remediation method in this example is basically the same as in Example 1, except that the curing time is 20 days. The oil content in the soil was measured before and after remediation, and the test results are shown in Table 2.

[0039] Table 2 Test data before and after soil remediation

[0040]

[0041] After curing for 20 days, the content of petroleum hydrocarbons decreased to 622mg / kg after adding yeast extract powder, and the degradation rate was 73.2%. After the treatment, the petroleum hydrocarbon content of the blank control CK was reduced to 2168mg / kg, and the degradation rate was 6.5%. Compared with curing for 30 days, the oil degradation rates of CK repaired by adding yeast extract powder and blank control were lower. The main reason is that the curing time is short and the microbial degradation is not complete.

Embodiment 3

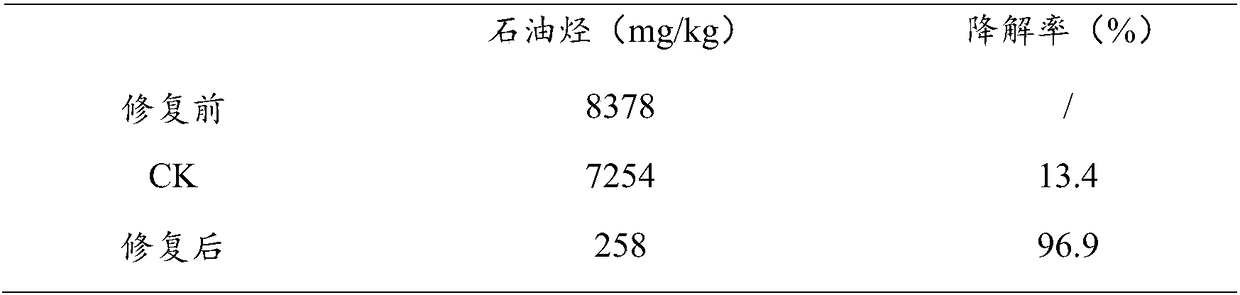

[0043]Firstly, the oil-contaminated soil is plowed, and the yeast extract powder aqueous solution is sprayed during the plowing process. Control the spraying amount of the yeast extract powder aqueous solution so that the weight of the yeast extract powder is 15% of the total amount of petroleum hydrocarbons in the petroleum-contaminated soil. The ambient temperature is 28-37°C, and the curing time is 35 days. Mix it every 3 days during the maintenance period. At the same time, the soil without yeast extract powder was used as the blank control CK, and the CK and the experimental group were maintained under the same moisture content and temperature conditions. The oil content in the soil was measured before and after remediation, and the test results are shown in Table 3.

[0044] Table 3 Test data before and after soil remediation

[0045]

[0046] The petroleum hydrocarbon content was reduced to 258mg / kg after adding yeast extract powder for restoration, and the degrad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com