A kind of preparation technology of multi-layer metal material golf head

A golf head and multi-layer metal technology, applied in metal processing equipment, manufacturing tools, welding equipment, etc., can solve the problems of multiple processing procedures, long cycle time, high cost, etc., and achieve energy saving on the surface quality of solder joints, stable nuclei dissolution, fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

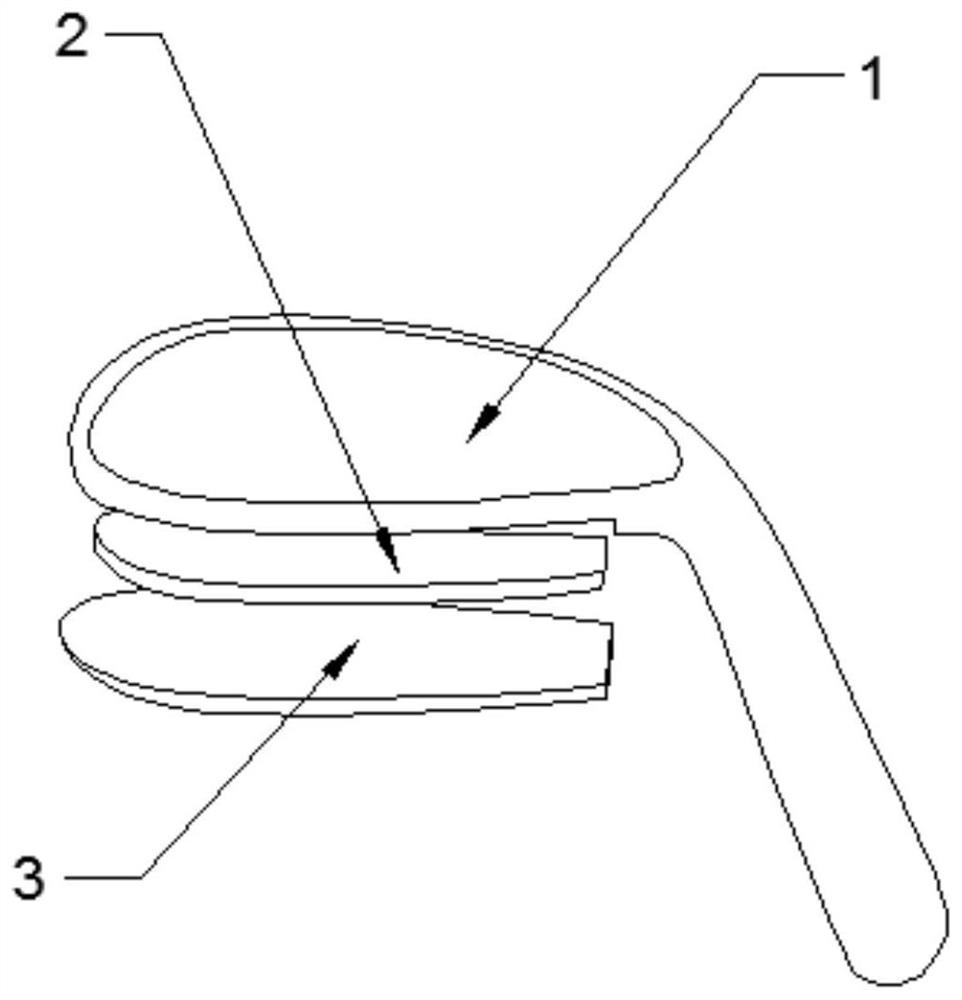

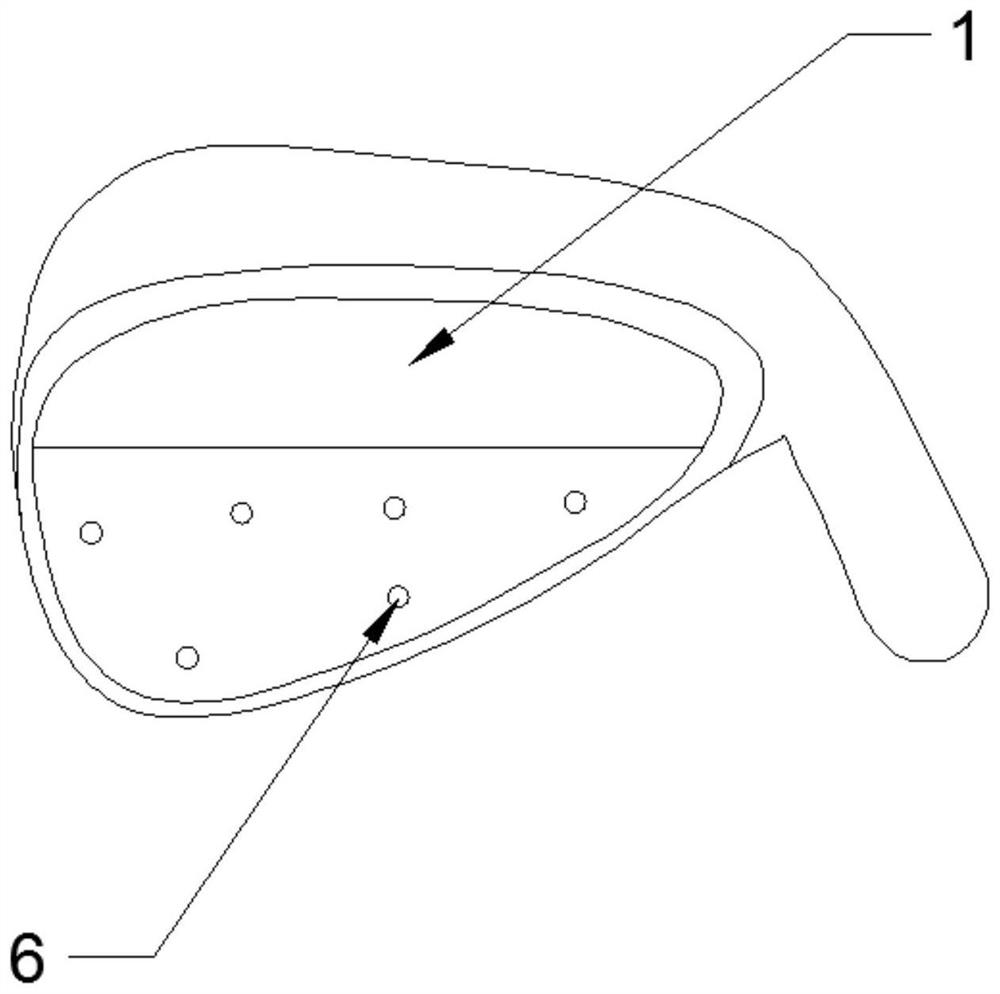

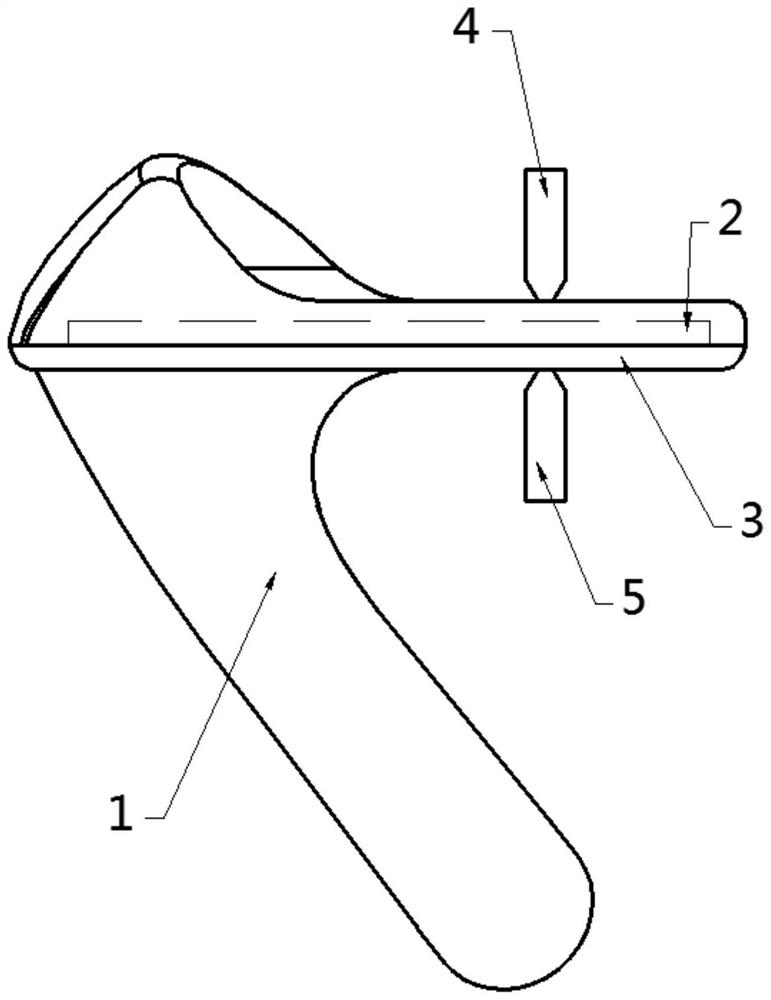

[0052] This embodiment takes 3 layers of metal material layers as an example, such as Figure 1-3 As shown, the golf head is composed of a ball head body 1, a transition layer 2 and a striking surface layer 3 arranged in sequence from top to bottom, which are the aforementioned three metal layers respectively, wherein the ball head body 1 and the striking surface layer 3 are composed of Made of carbon steel, the transition layer 2 is made of titanium alloy. Due to the low density of titanium alloy, the weight of the golf head can be reduced, so that the reduced weight can be added to the position where the golf head needs to be heavier in the form of counterweight. Concrete preparation process is as follows;

[0053] 1) polishing the mutual contact surfaces of the ball head body 1, the transition layer 2 and the striking surface layer 3;

[0054] 2) Assemble the polished ball head body 1 and the transition layer 2 according to the ball head process requirements;

[0055] 3) ...

Embodiment 2

[0065] This embodiment takes two layers of metal material layers as an example. The golf head is composed of a ball head body and a striking surface layer arranged in sequence from top to bottom, which are the aforementioned two layers of metal material layers, wherein the ball head body and the striking surface Layers are made of carbon steel. Concrete preparation process is as follows;

[0066] 1) polishing the mutual contact surfaces of the ball head body and the striking surface layer;

[0067] 2) Assemble the polished ball head body and striking surface layer together according to the ball head process requirements;

[0068] 3) Pressurize and spot-weld the assembled ball head body and striking surface layer on an intermediate frequency spot welding machine to obtain an intermediate product A;

[0069] 4) Apply pressure to the obtained intermediate product A on the hydraulic press, flatten and eliminate the gap between the ball head body and the striking surface layer, a...

Embodiment 3

[0077] This embodiment takes 4 layers of metal material layers as an example. The golf head is composed of a ball head body, 2 layers of transition layers and a striking surface layer arranged in sequence from top to bottom, which are the aforementioned 4 layers of metal material layers. The head body and the hitting surface layer are made of carbon steel, and the two transition layers are made of titanium alloy. Due to the low density of titanium alloy, the weight of the golf head can be reduced, and the reduced weight can be added to the golf ball in the form of counterweight. The head needs a weighted position. Concrete preparation process is as follows;

[0078] 1) The contact surfaces of the ball head body, the 2-layer transition layer and the striking surface layer are polished;

[0079] 2) Assemble the polished ball head body and one of the transition layers according to the ball head process requirements;

[0080] 3) Pressure spot welding the assembled ball head body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com