Manufacturing technology for transverse seamless technical veneer

A production process and technology, applied in the field of furniture manufacturing, can solve problems such as diversity and lack of three-dimensional sense, and achieve the effects of not easy adhesion, increased moisture absorption, and easy molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

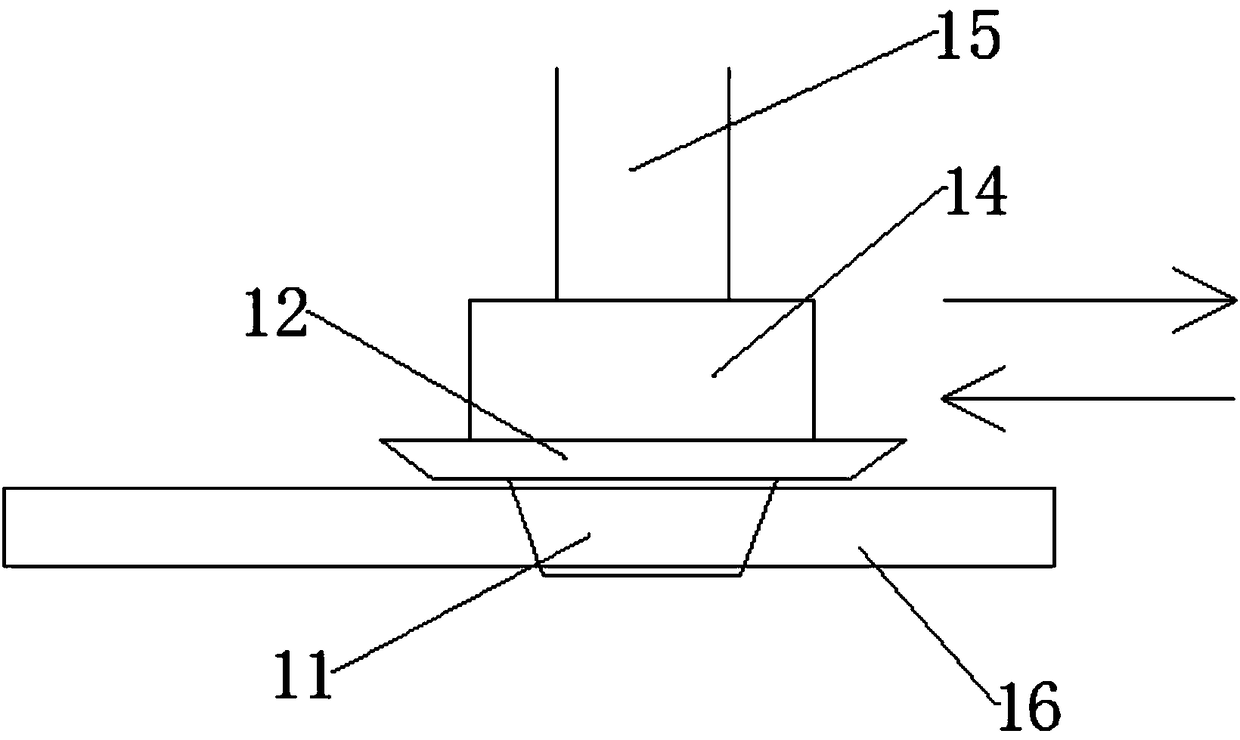

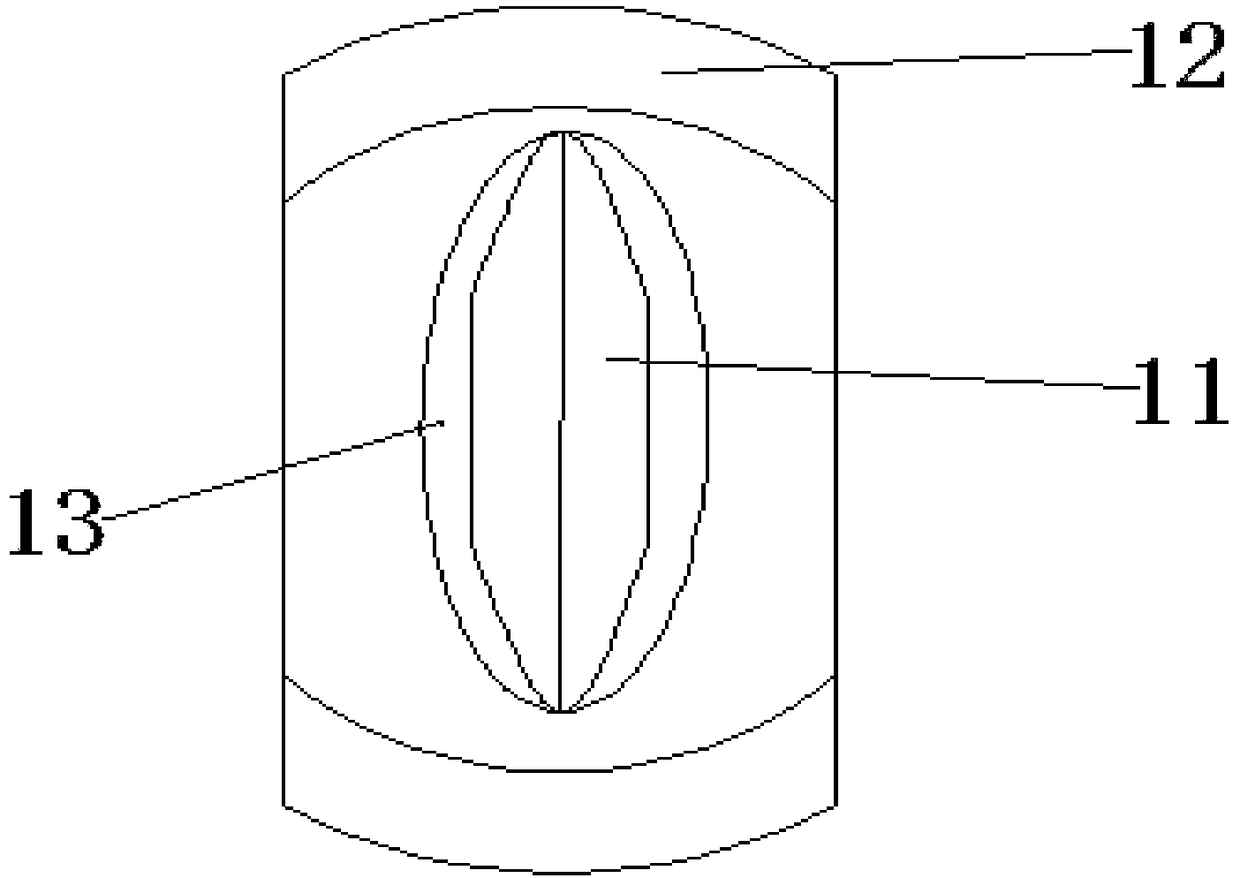

[0024]A production process of horizontal seamless technical leather, (1) raw material sorting: sorting with wood chips as raw materials: sorting wood chips with uniform color and luster; (2) drying raw materials: drying the sorted wood chips, and The drying temperature is: 18-25°C, and the moisture content of the sawdust is guaranteed to be <12% after drying; (3) Raw material molding: the dried sawdust is flat-pressed to a thickness of 3-5mm; (4) Forming and repairing: repair and sort the formed technical skins, and dig out the scarred parts of the technical skins to obtain technical skins with the same color; (5) Matching repair: take 2 to 3 pieces of formed and repaired technical skins Carry out stacking, in the process of stacking, ensure that the gaps between the technology skins are misaligned, and flatten the stacked technology skins; (6) Forming and gluing: the surface layer of the technology skins that have been flattened again Glue, the amount of glue applied is 260-3...

Embodiment 2

[0026] On the basis of Example 1, a drying liquid is placed in the storage environment in (7), and the drying liquid is sulfur, ammonia, and hydrogen peroxide mixed in proportion; the drying of the drying liquid is adopted in storage, adding The high-tech leather absorbs water, and at the same time avoids the bursting phenomenon that occurs when drying in the sun.

Embodiment 3

[0028] On the basis of above-mentioned embodiment 2, carry out UV finish coating to the other side that is coated with glue of science and technology leather after (7) step finishes; Increase the waterproof performance of science and technology leather and the glossiness of outer surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com