Steel pipe drawing emulsified oil with ultrahigh lubricating property and preparation method thereof

A technology of lubricating performance and emulsified oil, used in lubricating compositions, petroleum industry and other directions, can solve the problems of surface finish, brightness reduction, bad influence of heat treatment and annealing quality, and lack of matching lubricating oil for welded pipes. Not easy to deteriorate, prevent sintering, and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

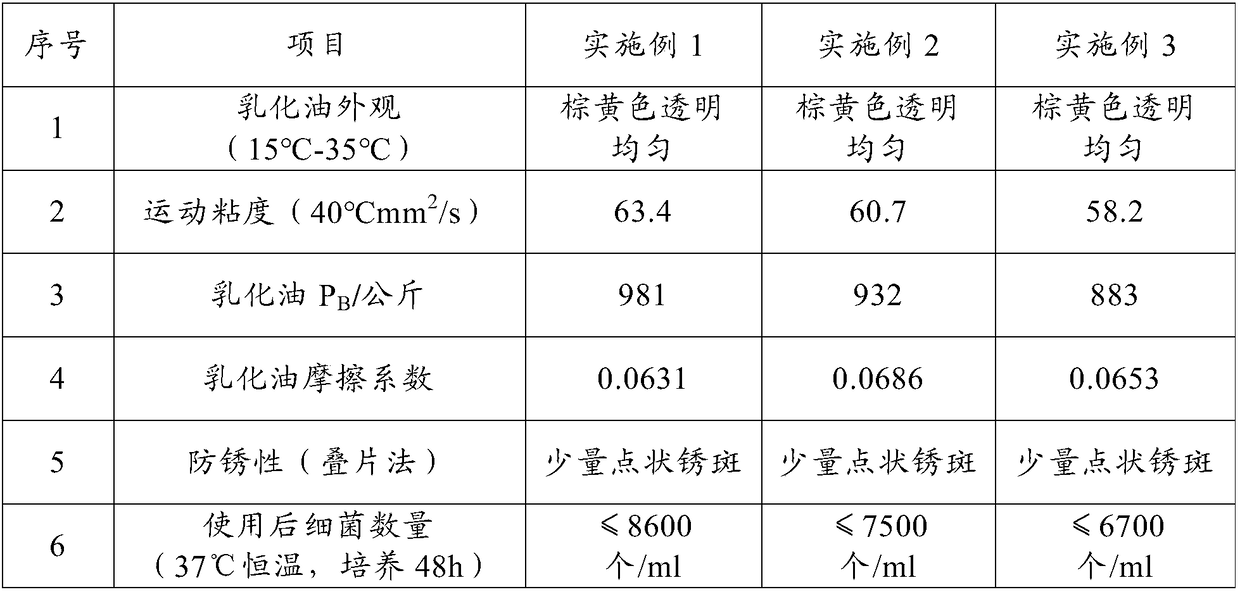

Examples

Embodiment 1

[0016] The formula of Example 1 is shown in the following table:

[0017] Serial number

[0018] Production method: According to the weight formula of each component in the above table, first put 120kg palm oil and 740kg mechanical oil N68 into a reactor at a speed of 50-120 revolutions per minute for heating and stirring. When the temperature reaches 60-80°C, then sequentially 2kg oil-soluble nano Fe 3 O 4 (2-50nm), 4kg nitrogen-containing borate, 2kg zinc dialkyl dithiophosphate, 30kg butyl stearate, 30kg C8-C10 mixed alcohol, 3kg sodium dodecylbenzene sulfonate and 3kg dimercaptothiol Diazole was added to the reaction kettle, kept warm and continuously stirred for 60-100 minutes, and then when the temperature dropped to 70°C, add 20kg sorbitan oleate Span80, 20kg nonylphenol polyoxyethylene ether, 20kg triethanolamine, 3kg of methyl silicone oil and 3kg of pentachloronitrobenzene, adjust the speed of the mixer to 30 rpm and keep stirring for 30-60 minutes, then stop heating...

Embodiment 2

[0020] The production method is the same as in Example 1, and the component names and their weight percentages are shown in the following table:

[0021] Serial number

[0022] Production method: According to the weight formula of each component in the above table, first put 150kg palm oil and 390kg mechanical oil N68 into a reactor at a speed of 50-120 revolutions per minute for heating and stirring. When the temperature reaches 60-80°C, then sequentially 10kg oil-soluble nano Fe 3 O 4 (2-50nm), 20kg nitrogen-containing borate, 30kg zinc dialkyl dithiophosphate, 60kg butyl stearate, 80kg C8-C10 mixed alcohol, 20kg sodium dodecylbenzene sulfonate and 15kg dimercaptothiol Diazole was added to the reactor, kept warm and continuously stirred for 60-100 minutes, and then when the temperature dropped to 70°C, 50kg sorbitan oleate Span80, 40kg nonylphenol polyoxyethylene ether, 80kg triethanolamine, 25kg methyl silicone oil and 30kg pentachloronitrobenzene, adjust the mixer speed to...

Embodiment 3

[0024] The formula of Example 3 is shown in the following table:

[0025] Serial number

Component name

Weight percentage (100%)

1

Oil-soluble nano Fe 3 O 4 (2-50nm)

15

2

Nitrogen-containing borate

30

3

Zinc dialkyl dithiophosphate

45

4

100

5

C8-C10 mixed alcohol

80

6

Sorbitan Oleate Span80

60

7

Polyoxyethylene nonylphenol ether

60

8

100

9

Sodium dodecyl benzene sulfonate

30

10

Dimercaptothiadiazole

20

11

30

12

Methyl silicone oil

40

13

180

14

Mechanical oil N68

210

[0026] Production method: According to the weight formula of each component in the above table, first put 180kg palm oil and 210kg mechanical oil N68 into a reactor at a speed of 50-120 revolutions per minute for heating and stirring. When the temperature reaches 60-80°C, then sequentially Put 15kg oil-soluble nano Fe 3 O 4 (2-50nm), 30kg nitrogen-containing borate, 45kg zinc dialkyl dithiophosphate, 100kg butyl stearate, 80kg C8-C10 mixed alcohol, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com