Device and method for evaluating carbon dioxide huffing-puffing recovery rate of shale oil

A carbon dioxide and evaluation method technology, applied in the field of petroleum engineering, can solve problems such as inability to obtain crude oil recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

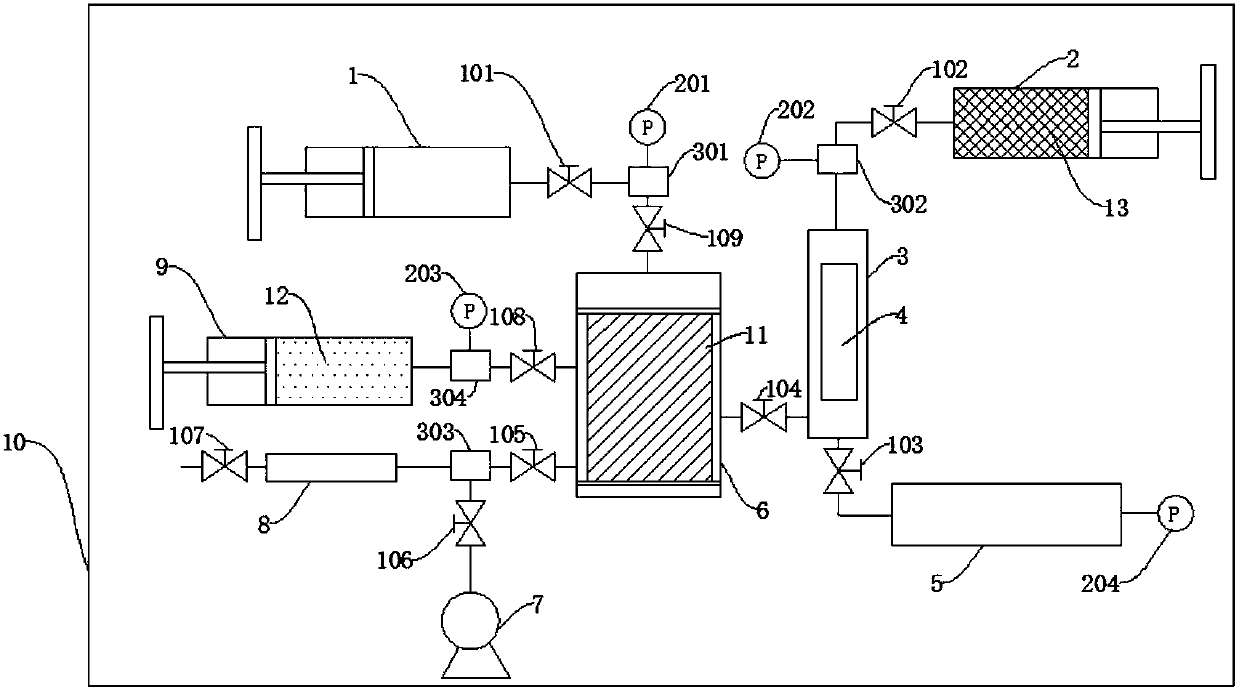

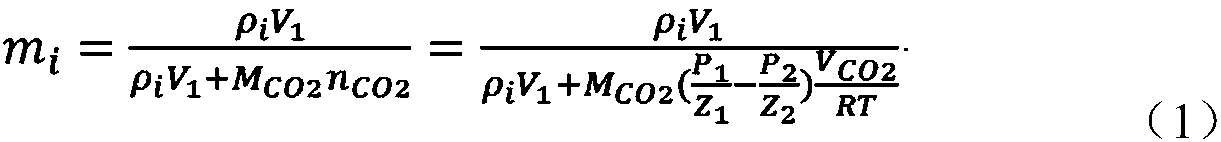

[0086] Set the temperature of the thermostat 10 at 60.0°C, select the shale sample that has been washed and dried, that is, the core 11, with a length of 3.982 cm and a diameter of 2.48 cm, and the weight of the core 11 is 39.177 g. The annular volume of holder 6 is 2.26cm 3 , into the radial core holder 6, open the first stop valve 101 and the ninth stop valve 109, and increase the confining pressure to the core 11 in the radial core holder 6 to 16 MPa through the confining pressure pump 1, after vacuuming , open the eighth shut-off valve 108, saturated dodecane 12, calculate the saturated dodecane 12 that enters to be 3.515g, open the third shut-off valve 103, inject a certain amount of CO in the visible container 3 2 When the gas reaches a pressure of 12MPa, open the fourth shut-off valve 104, keep the balance stable for 48 hours, close the fourth shut-off valve 104, open the seventh shut-off valve 107 and the fifth shut-off valve 105 for open-well production until the end ...

Embodiment 2

[0088] Set the temperature of the thermostat 10 at 60.0°C, select the shale sample that has been washed and dried, that is, the core 11, with a length of 3.982 cm and a diameter of 2.48 cm, and the weight of the core 11 is 39.177 g. The annular volume of holder 6 is 2.26cm 3 , into the radial core holder 6, open the first stop valve 101 and the ninth stop valve 109, and increase the confining pressure to the core 11 in the radial core holder 6 to 16 MPa through the confining pressure pump 1, after vacuuming , open the eighth cut-off valve 108, saturated dodecane 12, calculate the saturated dodecane 12 to be 3.514g, open the second cut-off valve 102, and inject a certain volume of isopropyl in the visible container 3 through the micro-injection pump 2 Alcohol 13, open the third shut-off valve 103, inject a certain amount of CO in the visible container 3 2 gas to isopropanol 13 with CO 2 Mixed phases, depending on the pressure of container 3 to 12MPa, calculate isopropanol 13 ...

Embodiment 3

[0090]Set the temperature of the thermostat 10 at 60.0°C, select the shale sample that has been washed and dried, that is, the core 11, with a length of 3.982 cm and a diameter of 2.48 cm, and the weight of the core 11 is 39.177 g. The annular volume of holder 6 is 2.26cm 3 , into the radial core holder 6, open the first stop valve 101 and the ninth stop valve 109, and increase the confining pressure to the core 11 in the radial core holder 6 to 16 MPa through the confining pressure pump 1, after vacuuming , open the eighth cut-off valve 108, saturated dodecane 12, calculate the saturated dodecane 12 to be 3.515g, open the second cut-off valve 102, and inject a certain volume of isopropyl in the visible container 3 through the micro-injection pump 2 Alcohol 13, open the third shut-off valve 103, inject a certain amount of CO in the visible container 3 2 gas to isopropanol 13 with CO 2 Mixed phases, depending on the pressure of container 3 to 12MPa, calculate isopropanol 13 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com