Xanthan gum gel electrolyte and preparation method thereof

A technology of colloidal electrolyte and xanthan gum, which is applied in the field of electrochemistry, can solve problems such as difficulty in dispersion, loss of colloidal characteristics, and short life, and achieve the effects of reducing the generation of lead sulfate, increasing overall stability, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

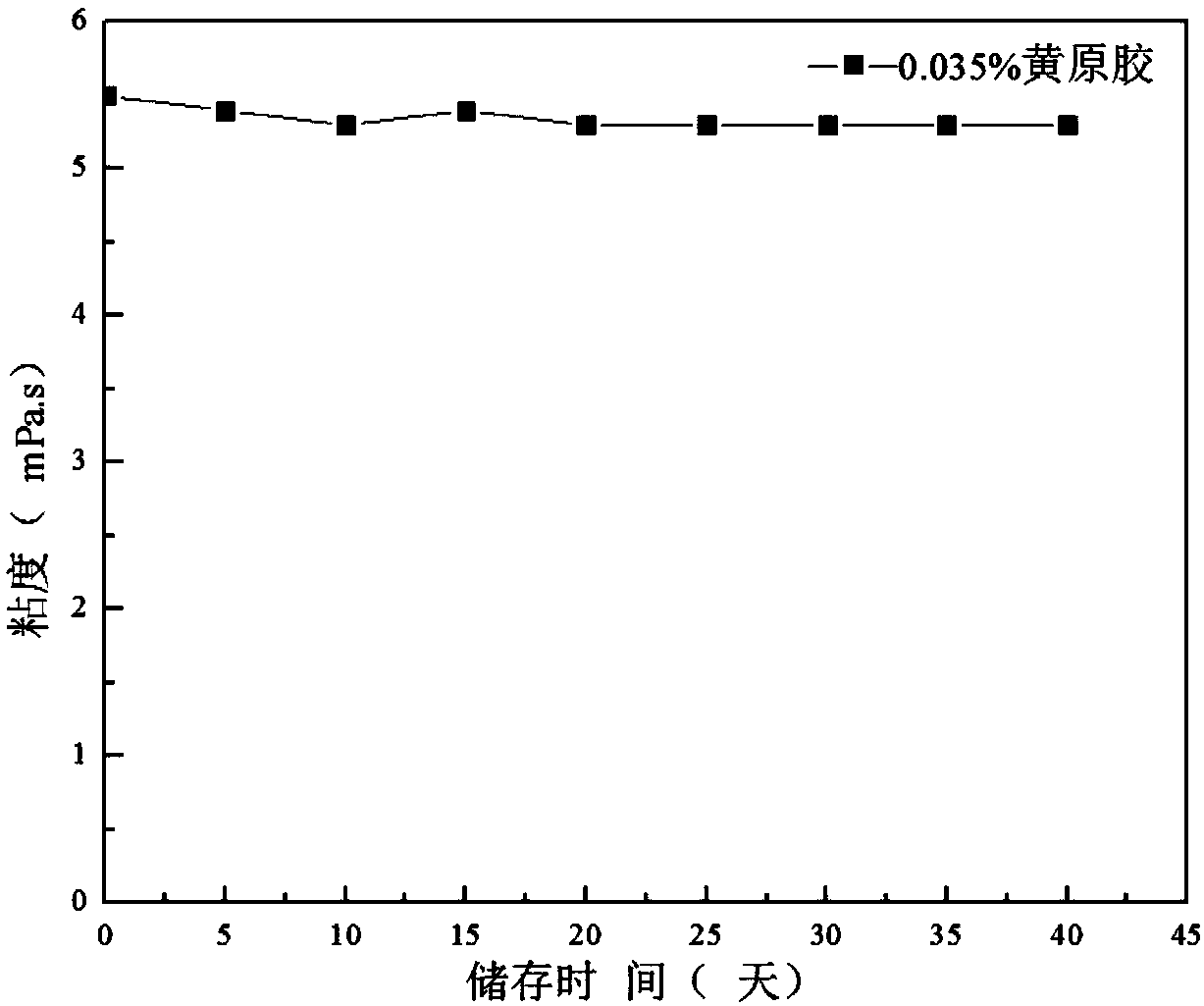

[0029] A kind of xanthan gum colloidal electrolyte, this colloidal electrolyte contains 985ml, density is 1.290g / cm 3 sulfuric acid, anhydrous sodium sulfate of 10.8g and xanthan gum of 0.42g;

[0030] The viscosity of the xanthan gum is 1200-1600 MPa·s, and the pH value is 6.0-8.0; the particle size of the xanthan gum is ≤179 μm;

Embodiment 2

[0032] A kind of xanthan gum colloidal electrolyte, this colloidal electrolyte contains 1000ml, density is 1.290g / cm 3 sulfuric acid, 15.4g of anhydrous sodium sulfate and 0.39g of xanthan gum.

[0033] The viscosity of the xanthan gum is 1200-1600 MPa·s, and the pH value is 6.0-8.0; the particle size of the xanthan gum is ≤179 μm;

Embodiment 3

[0035] A xanthan gum colloidal electrolyte, the colloidal electrolyte contains 1000ml of sulfuric acid with a density of 1.290g / cm3, 10g of anhydrous sodium sulfate and 0.51g of xanthan gum.

[0036] The viscosity of the xanthan gum is 1200-1600 MPa·s, and the pH value is 6.0-8.0; the particle size of the xanthan gum is ≤179 μm;

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com