High-quality coconut-oil microencapsulated powder grease and high-efficiency preparation method thereof

A technology of microencapsulation and powdered oil, which is applied in the fields of edible oil/fat, food science, application, etc., can solve the problems of slow dissolution rate of wall material solution, uneven milk droplets of coarse emulsion, and a large amount of foam, so as to achieve uniform increase Performance and stability, high yield, and improved utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

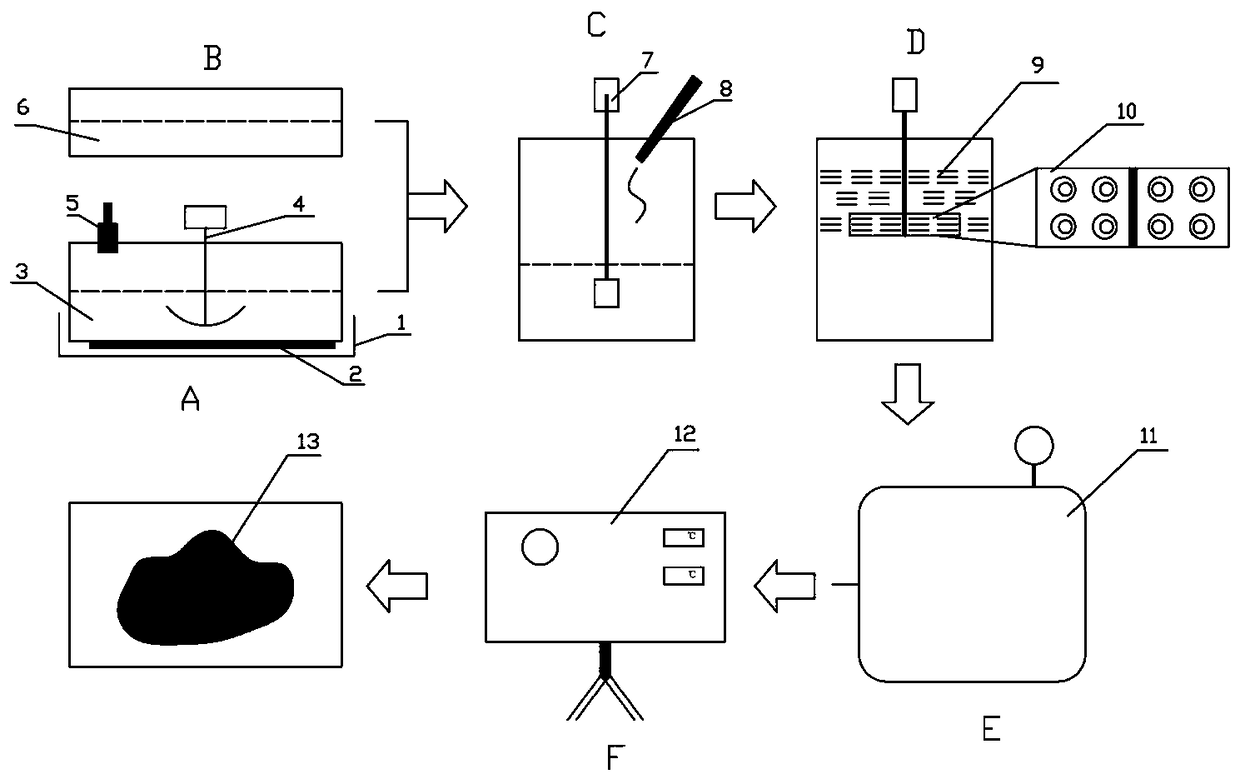

[0030] As stated, the raw material ratio (in mass percentage) of the coconut oil powder is: 19% soybean protein isolate, 40% maltodextrin, 10% gum arabic, 1% sucrose fatty acid ester, and 30% coconut oil.

[0031] As described, the wall material solution 3 is first prepared, and the heater 2 and the controllable stirring device 4 are used to dissolve the wall material. Bacterial effect, improve the storage and antioxidant stability of the system. The wall material is a mixture of soybean protein isolate, maltodextrin and gum arabic, the emulsifier is sucrose fatty acid ester, the solid content of the wall material solution is 40%, the temperature of the heater 2 is 60-80 °C, and the temperature of the controllable stirring device 4 is The stirring speed is 300-500 rpm.

[0032] As mentioned above, the wall material is combined with the ultrasonic device 1 and the vacuum device 5. Due to the stirring effect, there will be a little air bubbles in the upper layer of the wall mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com