Nano-hydroxyapatite-modified polyurethane urea bone repair material and preparation method thereof

A technology of nano-hydroxyapatite and repair materials, which is applied in the fields of pharmaceutical formula, medical science, prosthesis, etc., can solve problems such as unfavorable cell growth, achieve good biocompatibility, excellent performance, and promote bone regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

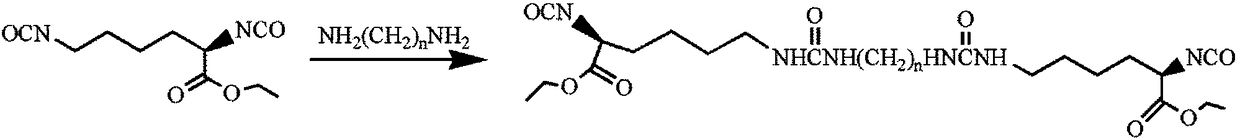

[0058] The preparation method of LBL is: under the protection of dry nitrogen and mechanical stirring, add 1,4-butanediamine dropwise to L-lysine diisocyanate (-NCO:-NH 2 =8:1, molar ratio), after reacting at room temperature for 2h, add four times the volume of n-hexane to the reaction product, after stirring evenly, obtain a white solid by suction filtration, wash with n-hexane repeatedly until the filtrate IR detects that there is no -NCO absorption Peak (2270cm -1 ), vacuum-dried to constant weight to obtain white powder LBL. LBL's 1 H NMR structure characterization results: 1 H NMR (DMSO-D6, ppm): 1.27-1.32 (m, 10H, CH 3 CH 2 and C H 2 CH 2 CHNCO), 1.52-1.55(m,8H, CH 2 CH 2 NH),1.75(q,4H, CH 2 CHNCO),3.08-3.16(t,8H, CH 2 NH), 4.08-4.15 (m, 6H, CH-NCO and CH 3 C H 2 ), 5.95-6.04 (br, N H ).

[0059] The preparation method of LHL is: under the protection of dry nitrogen and mechanical stirring, add 1,6-butanediamine dropwise to L-lysine diisocyanate ...

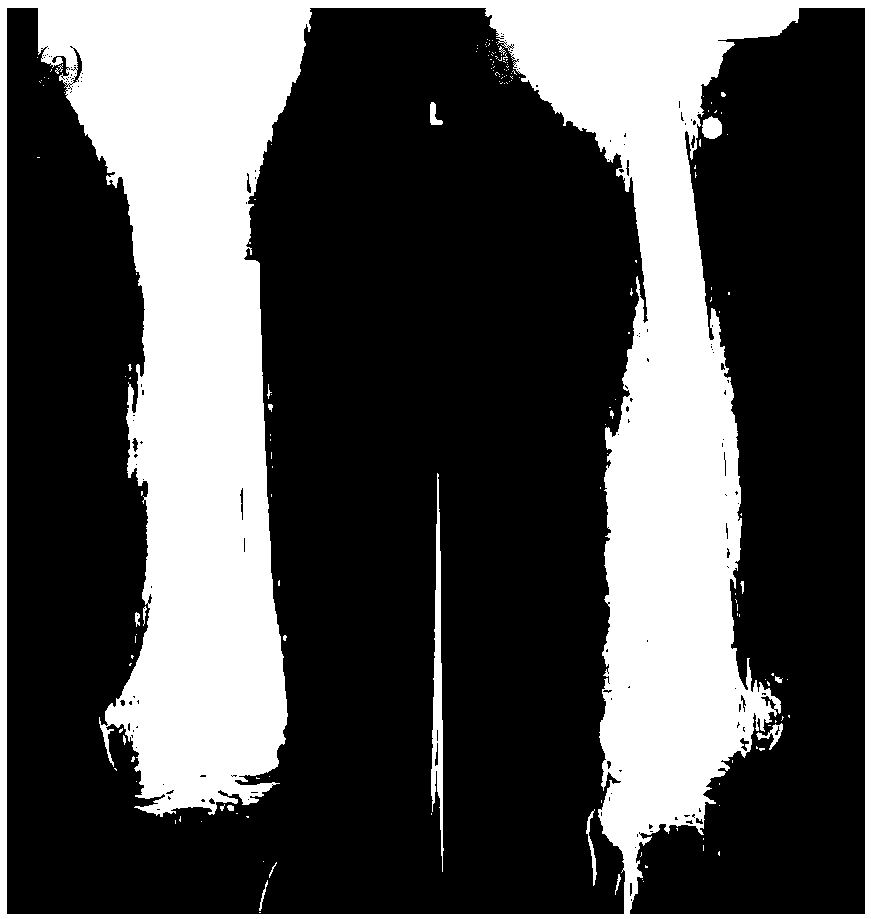

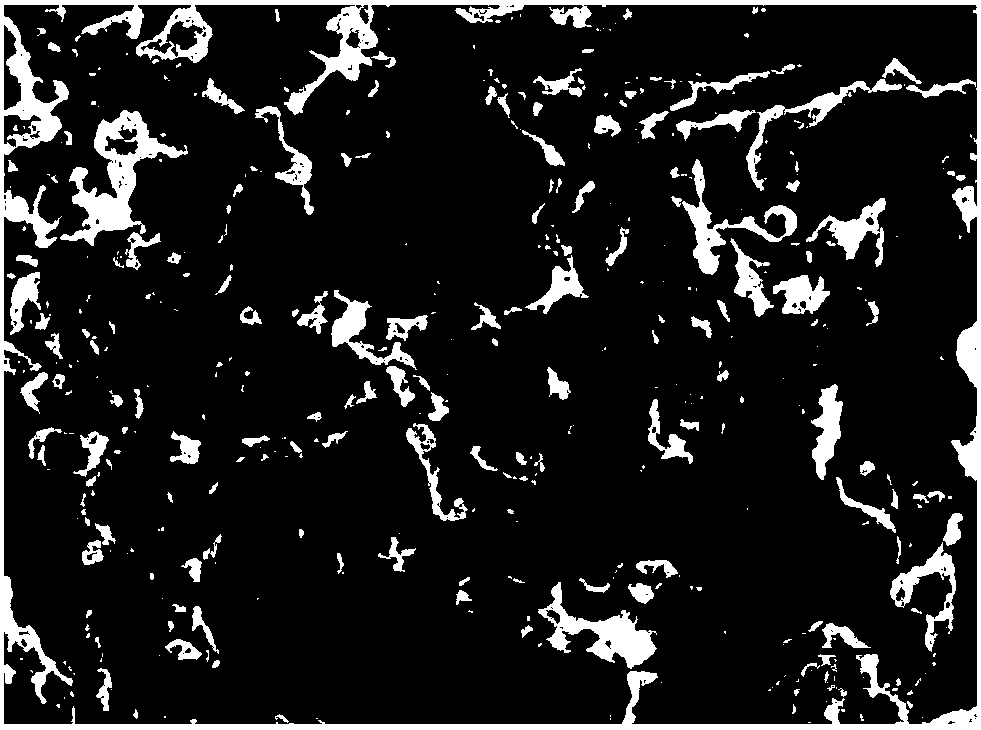

Embodiment 1

[0061] 4.5g double-terminal hydroxyl PPDO (3mmol, M n =1500) was dissolved in 20mL DMF, protected by dry nitrogen, mechanically stirred, adding 2.25g of nano-sized nano-hydroxyapatite (average particle size is 50nm) in batches, stirred evenly, heated up to 80°C, added chain extender LBL DMF solution (0.4g / mL), control the molar ratio of -NCO to -OH to be 1.3:1, keep the reaction temperature until the -NCO content is close to the theoretical value, about 4.5h, dilute DMF to 15g / 100mL, drop to room temperature, and then Add 0.397mmol pentaerythritol and stir well. Slowly pour into the mold, react at room temperature for 96 hours, and cross-link. Soak the molded product in 3 times the volume of deionized water, soak for 4 hours, repeat three times, then soak in 3 times the volume of absolute ethanol, soak for 4 hours, repeat three times, dry at room temperature to constant weight, and obtain the honeycomb bone repair material a.

Embodiment 2

[0063] 6.0g double-terminal hydroxyl PPDO (3mmol, M n=2000) was dissolved in 20mL DMF, protected by dry nitrogen, mechanically stirred, adding 3.0g of nano-sized nano-hydroxyapatite (average particle size is 60nm) in batches, stirred evenly, heated up to 80°C, added chain extender LBL DMF solution (0.4g / mL), control the molar ratio of -NCO to -OH to be 1.3:1, keep the reaction temperature until the -NCO content is close to the theoretical value, about 4.5h, dilute DMF to 15g / 100mL, drop to room temperature, and then Add 0.454mmol pentaerythritol and stir well. Slowly pour into the mold, react at room temperature for 96 hours, and cross-link. Soak the molded product in 4 times the volume of deionized water, soak for 4 hours, repeat three times, then soak in 4 times the volume of absolute ethanol, soak for 4 hours, repeat three times, dry at room temperature to constant weight, and obtain the honeycomb bone repair material b.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com