Environment-friendly water-based fire extinguishing agent

A kind of fire extinguishing agent and environment-friendly technology, applied in the field of environment-friendly water-based fire extinguishing agents, can solve the problems of inflow, pollution, seepage into the ground, etc., and achieve the effects of improving spray performance, reducing usage, and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

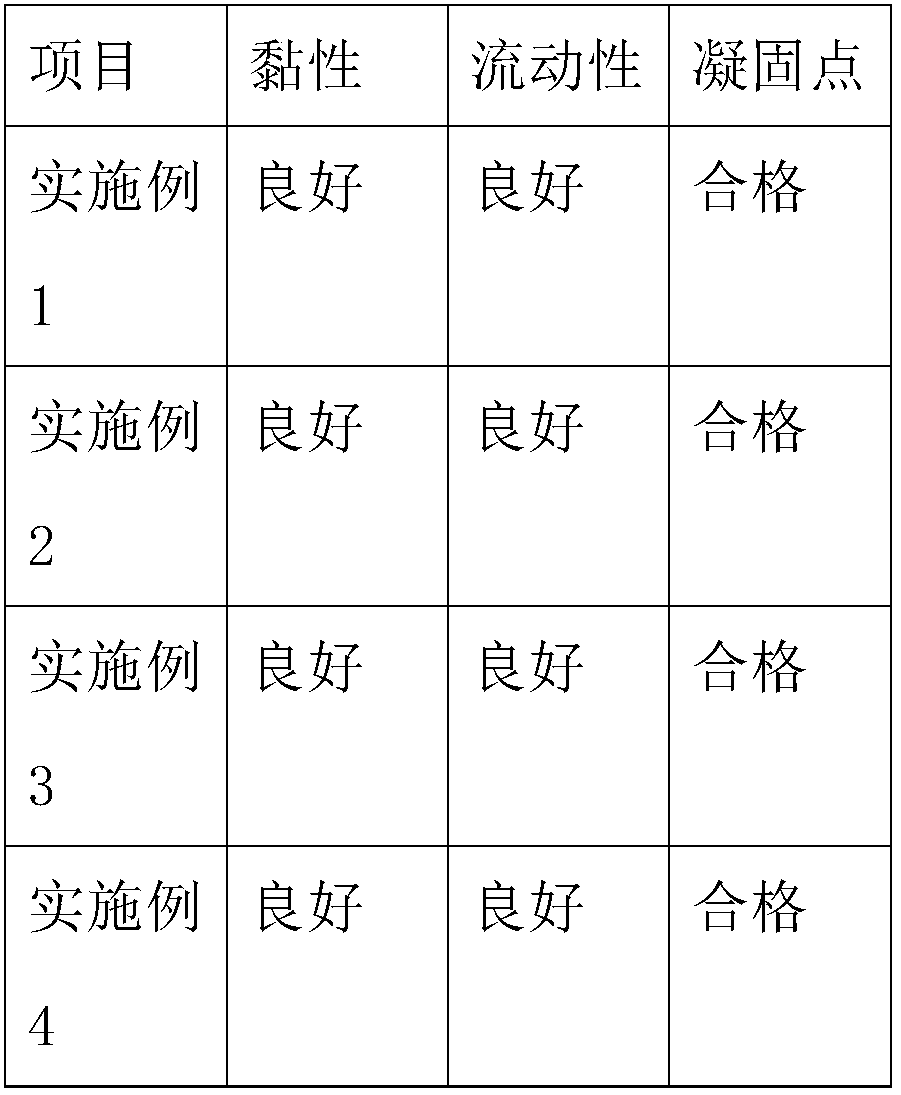

Examples

Embodiment 1

[0020] (1) Preparation of inorganic salts

[0021] It is prepared by mixing 10 parts by mass of ammonium hydrogen phosphate, 15 parts of ammonium dihydrogen phosphate, 8 parts of phosphobenzoic acid, 1 part of calcium hydroxide and 20 parts of water.

[0022] (2) Preparation of antifreeze

[0023] Mix 12 parts of polyethylene glycol, 6 parts of polyvinyl alcohol, 6 parts of glycerin, and 40 parts of water, and then perform high-speed stirring for 2 hours to obtain an emulsion.

[0024] (3) Preparation of stabilizer

[0025] Mix 12 parts of urea, 1 part of sodium bisulfite, 2 parts of sodium dodecylsulfonate, and 25 parts of water to obtain a product after mixing evenly.

[0026] (4) Preparation of hydrocarbon surfactant

[0027] A substance prepared by mixing 20 parts of amphoteric imidazoline with 18 carbon atoms, 10 parts of betaine, and 2 parts of sodium stearate at 70°C with 35 parts of water.

[0028] (5) Preparation of thermosensitive hydrogel

[0029] 12 parts by m...

Embodiment 2

[0033] (1) Preparation of inorganic salts

[0034] It is prepared by mixing 15 parts by mass of ammonium hydrogen phosphate, 18 parts of ammonium dihydrogen phosphate, 7 parts of phosphobenzoic acid, 1 part of calcium hydroxide and 25 parts of water.

[0035] (2) Preparation of antifreeze

[0036] 15 parts of polyethylene glycol, 6 parts of polyvinyl alcohol, 10 parts of glycerin, and 50 parts of water were mixed, and then stirred at a high speed for 3 hours to obtain an emulsion.

[0037] (3) Preparation of stabilizer

[0038] Mix 15 parts of urea, 2 parts of sodium bisulfite, 2 parts of sodium dodecylsulfonate, and 25 parts of water to obtain a product after mixing evenly.

[0039] (4) Preparation of hydrocarbon surfactant

[0040] A substance prepared by mixing 25 parts of amphoteric imidazolines with 15 carbon atoms, 15 parts of betaine, and 4 parts of sodium stearate at 75°C with 40 parts of water.

[0041] (5) Preparation of thermosensitive hydrogel

[0042] 15 part...

Embodiment 3

[0046] (1) Preparation of inorganic salts

[0047]It is prepared by mixing 20 parts by mass of ammonium hydrogen phosphate, 20 parts of ammonium dihydrogen phosphate, 6 parts of phosphobenzoic acid, 1 part of calcium hydroxide and 20 parts of water.

[0048] (2) Preparation of antifreeze

[0049] 10 parts of polyethylene glycol, 6 parts of polyvinyl alcohol, 6 parts of glycerin, and 40 parts of water were mixed, and then stirred at a high speed for 2 hours to obtain an emulsion.

[0050] (3) Preparation of stabilizer

[0051] Mix 12 parts of urea, 2 parts of sodium bisulfite, 2 parts of sodium dodecylsulfonate, and 22 parts of water, and mix them uniformly to obtain a product.

[0052] (4) Preparation of hydrocarbon surfactant

[0053] A substance prepared by mixing 20 parts of amphoteric imidazolines with 12 carbon atoms, 10 parts of betaine, and 6 parts of sodium stearate at 70°C with 30 parts of water.

[0054] (5) Preparation of thermosensitive hydrogel

[0055] The m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com