Tea-carbon water purifying material, and preparation method and application thereof

A technology for purifying water and tea charcoal, which is applied in chemical instruments and methods, water pollutants, and other chemical processes, etc., can solve the problems of waste of tea tree branches, and there is no application of tea charcoal, and achieves important practical promotion value and preparation method. Simple and controllable, the effect of strong market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

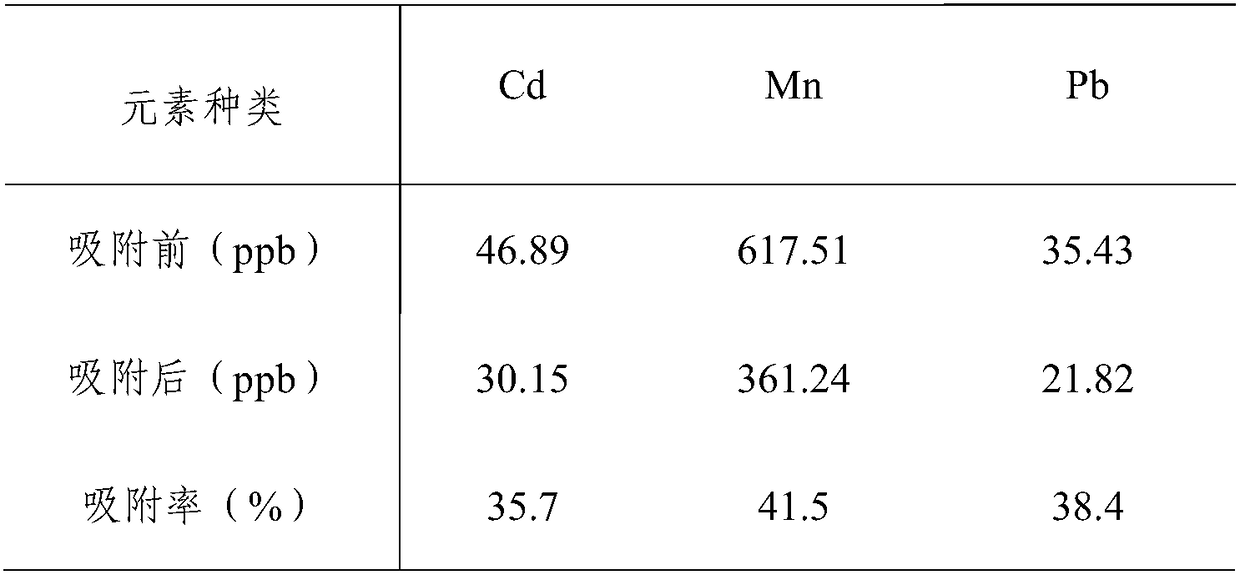

[0026] A tea charcoal water purification material is prepared from branches mowed in winter. The preparation method specifically includes collecting clean tea tree branches as raw materials, sintering at a high temperature of 650° C. for 2 hours, carbonizing until smokeless, and crushing.

[0027] In this example, the pore diameter of the obtained tea charcoal water purification material is 500nm-65μm, and the specific surface area is 124m 2 / g.

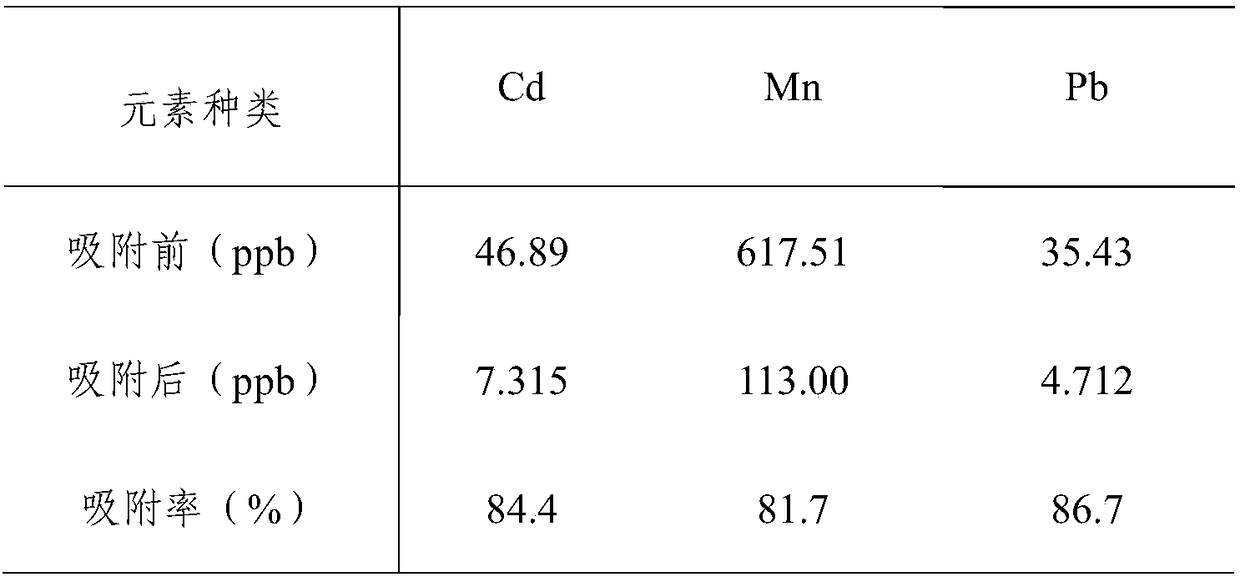

[0028] The test results of dynamic adsorption show that the removal rate of sediment, heavy metals and dyes is 85.3% when the tea charcoal water purification material is loaded into the filter column with a height-to-diameter ratio of 20 and the flow rate is controlled at 5ml / min.

[0029] Put the dried tea charcoal water purification materials into the concentration of 1.5×10 -4 mol / L rhodamine B solution and methylene blue solution, and with stirring, the stirring speed is 300rpm, and the concentration is tested every 20min during...

Embodiment 2

[0037] A tea charcoal water purification material is prepared from branches pruned in autumn. The preparation method specifically includes collecting clean tea tree branches as raw materials, drying at 85°C until the water content is 2%, and then pressing at 12MPa for 10 minutes, and Sinter at a high temperature of 780°C for 6 hours, carbonize until there is no smoke, pulverize at 450rpm for 3 minutes, and pass through a 160-mesh sieve.

[0038] In this example, the pore diameter of the obtained tea charcoal water purification material is 850nm-15μm, and the specific surface area is 186m 2 / g.

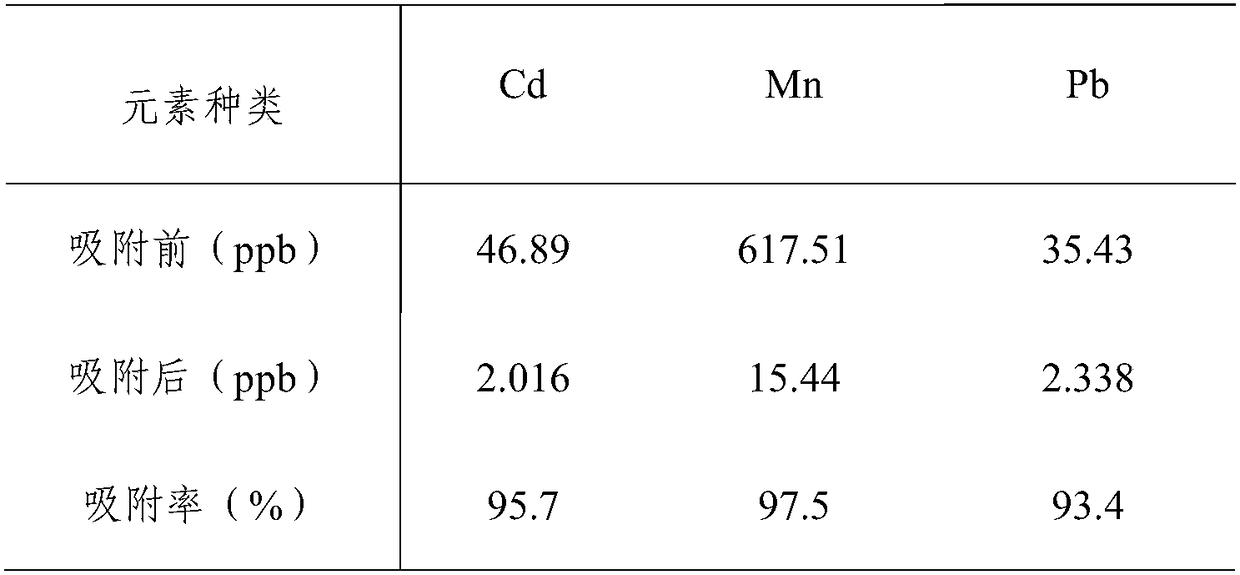

[0039] The test results of dynamic adsorption show that the removal rate of sediment, heavy metals and dyes is 93.3% when the tea-charcoal water purification material is loaded into a filter column with a height-to-diameter ratio of 20 and the flow rate is controlled at 5ml / min.

[0040] Put the dried tea charcoal water purification materials into the concentration of 1.5×10 -4 mol / L...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com