Aminated graphene aerogel based efficient adsorbent as well as preparation method and application thereof

A technology of aminated graphene and aerogel, applied in graphene, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve the problems of low specific surface area, secondary pollution, difficult separation, etc., and improve the adsorption capacity , Improve the adsorption performance, and the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

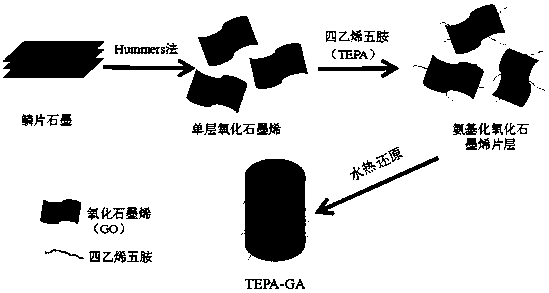

Method used

Image

Examples

Embodiment 1

[0031] (1) Dissolve 0.06 g of graphite oxide in 20 mL of distilled water, put it into an ultrasonic machine, and ultrasonicate for 1 h at an ultrasonic frequency of 100 Hz to obtain a uniformly dispersed aqueous solution of graphene oxide with a concentration of 3 mg / mL.

[0032] (2) Add 0.3mL tetraethylenepentamine to the graphene oxide aqueous solution in step (1), and stir with a magnetic stirrer for 5min at room temperature to obtain a uniform mixed solution;

[0033] (3) Transfer the mixed solution obtained in the above step (2) into a 100mL high-temperature and high-pressure hydrothermal reactor with a polytetrafluoroethylene liner, and react at 180°C for 12h;

[0034] (4) The product obtained in step (3) was dialyzed and washed with 10% ethanol aqueous solution until the dialysate was neutral to obtain a hydrogel, which was freeze-dried for more than 36 hours to obtain an aerogel.

Embodiment 2

[0036] (1) Dissolve 0.06 g of graphite oxide in 20 mL of distilled water, put it into an ultrasonic machine, and ultrasonicate for 1 h at an ultrasonic frequency of 100 Hz to obtain a uniformly dispersed aqueous solution of graphene oxide with a concentration of 3 mg / mL.

[0037] (2) Add 0.5mL tetraethylenepentamine to the graphene oxide aqueous solution in step (1), and stir with a magnetic stirrer for 5min at room temperature to obtain a uniform mixed solution;

[0038] (3) Transfer the mixed solution obtained in the above step (2) into a 100mL high-temperature and high-pressure hydrothermal reactor with a polytetrafluoroethylene liner, and react at 180°C for 12h;

[0039] (4) The product obtained in step (3) was dialyzed and washed with 10% ethanol aqueous solution until the dialysate was neutral to obtain a hydrogel, which was freeze-dried for more than 36 hours to obtain an aerogel.

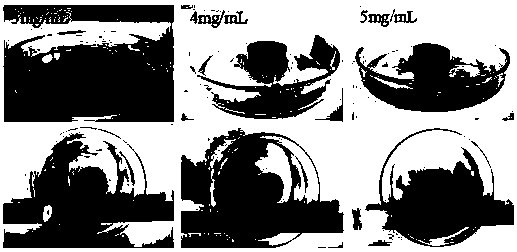

[0040] image 3 The photo of the aminated graphene obtained in this example standing on...

Embodiment 3

[0044] (1) Dissolve 0.06 g of graphite oxide in 20 mL of distilled water, put it into an ultrasonic machine, and ultrasonicate for 1 h at an ultrasonic frequency of 100 Hz to obtain a uniformly dispersed aqueous solution of graphene oxide with a concentration of 3 mg / mL.

[0045] (2) Add 1 mL of tetraethylenepentamine to the graphene oxide aqueous solution in step (1), and stir with a magnetic stirrer for 5 min at room temperature to obtain a uniform mixed solution;

[0046] (3) Transfer the mixed solution obtained in the above step (2) into a 100mL high-temperature and high-pressure hydrothermal reactor with a polytetrafluoroethylene liner, and react at 180°C for 12h;

[0047] (4) The product obtained in step (3) was dialyzed and washed with 10% ethanol aqueous solution until the dialysate was neutral to obtain a hydrogel, which was freeze-dried for more than 36 hours to obtain an aerogel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com