Technology for treating electroplating wastewater

A technology of electroplating wastewater and treatment process, which is applied in the direction of metallurgical wastewater treatment, water/sewage treatment, water/sewage multi-stage treatment, etc. It can solve the problems of difficult operation, high cost, environmental pollution, etc., achieve efficient treatment and discharge, reduce The effect of processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

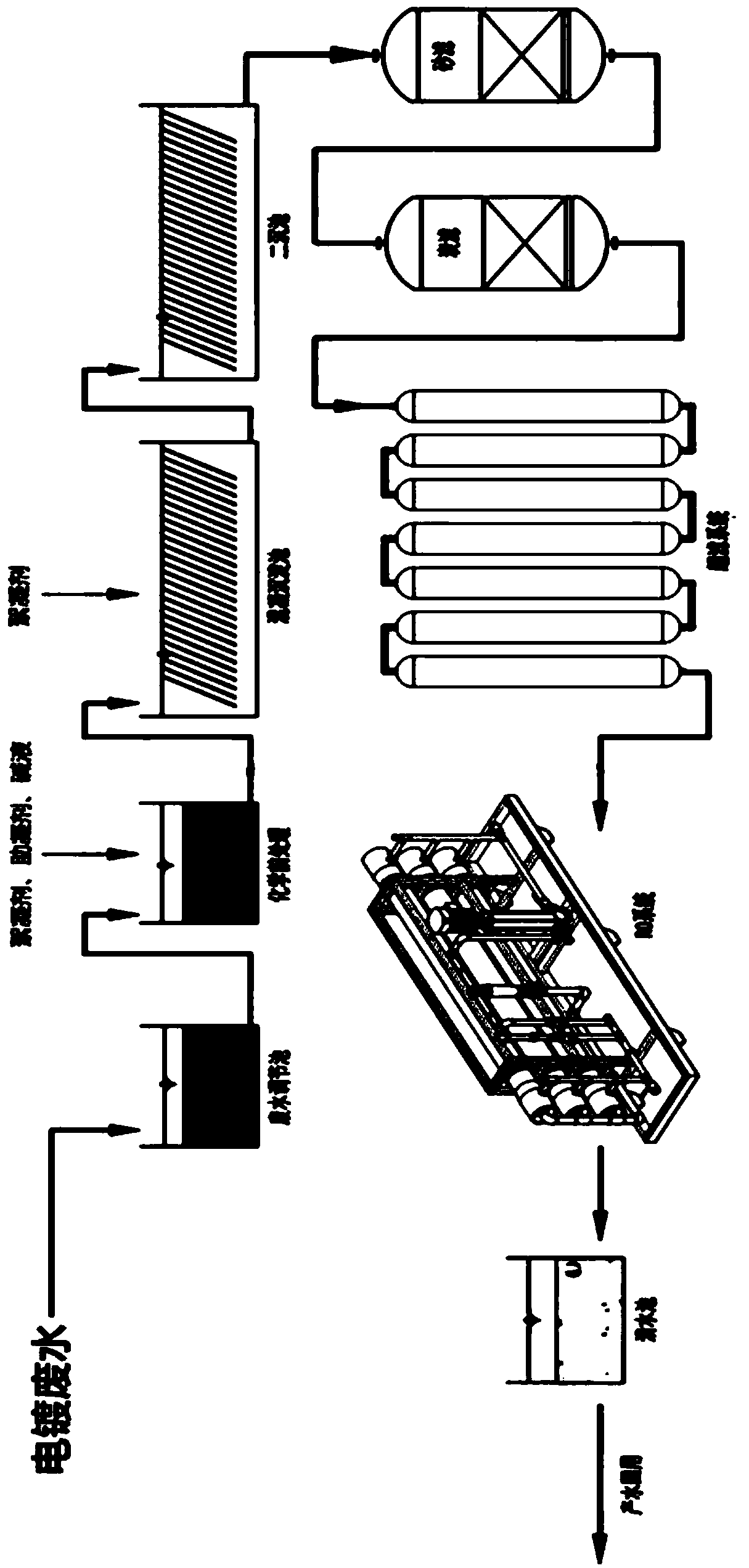

Image

Examples

Embodiment 1

[0025] (1) Import the collected electroplating wastewater into the wastewater regulating tank for equalization and adjustment treatment to buffer the wastewater treatment load, reduce the fluctuation of wastewater flow into the subsequent treatment system, and initially precipitate high-concentration harmful sedimentation substances;

[0026] (2) After the water quantity and water quality in the wastewater regulating tank are relatively stable, transport it to the pretreatment tank, add diatomaceous earth coagulant, lye (26% sodium hydroxide solution) in turn, and stir and mix evenly for a period of time Realize chemical pretreatment, wherein the stirring speed is 71r / min, and the time is 26min;

[0027] (3) Transport the wastewater pretreated in step (2) to the coagulation sedimentation tank, add flocculant (combination of inorganic flocculant (alum, aluminum sulfate, polyferric sulfate, etc.) and polyacrylamide series flocculant), After stirring and mixing evenly, immerse fo...

Embodiment 2

[0032] (1) Import the collected electroplating wastewater into the wastewater regulating tank for equalization and adjustment treatment to buffer the wastewater treatment load, reduce the fluctuation of wastewater flow into the subsequent treatment system, and initially precipitate high-concentration harmful sedimentation substances;

[0033] (2) After the water volume and water quality in the wastewater regulating tank are relatively stable, it is transported to the pretreatment tank, and coagulant aids (one or two combinations of bentonite, diatomaceous earth, and calcium oxide) and lye ( 26% sodium hydroxide solution) and realize chemical pretreatment after stirring and mixing uniformly for a period of time, wherein the stirring speed is 65r / min, and the time is 30min;

[0034] (3) Transport the wastewater pretreated in step (2) to the coagulation sedimentation tank, and add an alum flocculant (a combination of an inorganic flocculant (alum, aluminum sulfate, polyferric sulf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com