Preparation method, preservation method and application for rhodium-palladium alloy

A technology of palladium alloy and palladium salt, which is applied in the field of preparation of rhodium-palladium alloy, to achieve the effect of facilitating electron transmission, improving electron transmission performance, and good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

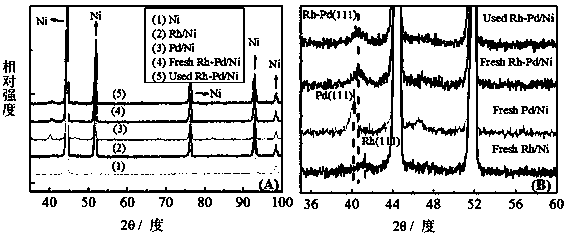

[0049] Add RhCl to the same aqueous solution system at 30°C under air atmosphere 3 To a concentration of 1 mM, add PdCl 2 At the same time, the supporting electrolyte NaCl was added to a concentration of 1 M, and the pH was adjusted to 2 with concentrated hydrochloric acid. Nickel foam was used as the substrate material, and the aqueous solution system was stirred, and a rhodium-palladium alloy was obtained by electrodepositing at a current of 4 mA.

[0050] The foamed nickel needs to be pretreated as follows: first place the foamed nickel in acetone for 20 minutes of ultrasonic treatment for degreasing and cleaning; then in 80g / L dilute H 2 SO 4 Soak in the solution for 5 minutes to remove the oxide layer on the surface of the material; then wash it with deionized water until it is clean.

Embodiment 2

[0052] Add RhCl to the same aqueous solution system at 10°C under air atmosphere 3 To a concentration of 0.5 mM, add PdCl 2 At the same time, the supporting electrolyte KCl was added to a concentration of 0.6 M, and the pH was adjusted to 1.8 with concentrated hydrochloric acid. Nickel foam was used as the base material, and the aqueous solution system was stirred, and a rhodium-palladium alloy was obtained by electrodepositing at a current of 3 mA.

[0053] The nickel foam needs to be pretreated as follows: first place the nickel foam in acetone for 5 minutes of ultrasonic treatment for degreasing and cleaning, repeat three times; then in 75g / L dilute H 2 SO 4 Soak in the solution for 2 minutes to remove the oxide layer on the surface of the material; then wash it with deionized water until it is clean.

Embodiment 3

[0055] Add RhCl to the same aqueous solution system at 50°C under air atmosphere 3 To a concentration of 2 mM, add PdCl 2 At the same time, the supporting electrolyte NaCl was added to a concentration of 1.8 M, and the pH was adjusted to 2.4 with concentrated hydrochloric acid. Nickel foam was used as the base material, and the aqueous solution system was stirred, and a rhodium-palladium alloy was obtained by co-electrodeposition at a current of 10 mA.

[0056] The foamed nickel needs to be pretreated as follows: first place the foamed nickel in acetone for 60 minutes of ultrasonic treatment for degreasing and cleaning; then in 85g / L dilute H 2 SO 4 Soak in the solution for 20 minutes to remove the oxide layer on the surface of the material; then wash it with deionized water until it is clean.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com