Chemical reaction device and application thereof

A technology of reaction unit and synthesis reactor, which is used in organic chemistry, chemical instruments and methods, preparation of organic compounds, etc., to achieve the effects of good selectivity, high yield of target products, and high conversion rate of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

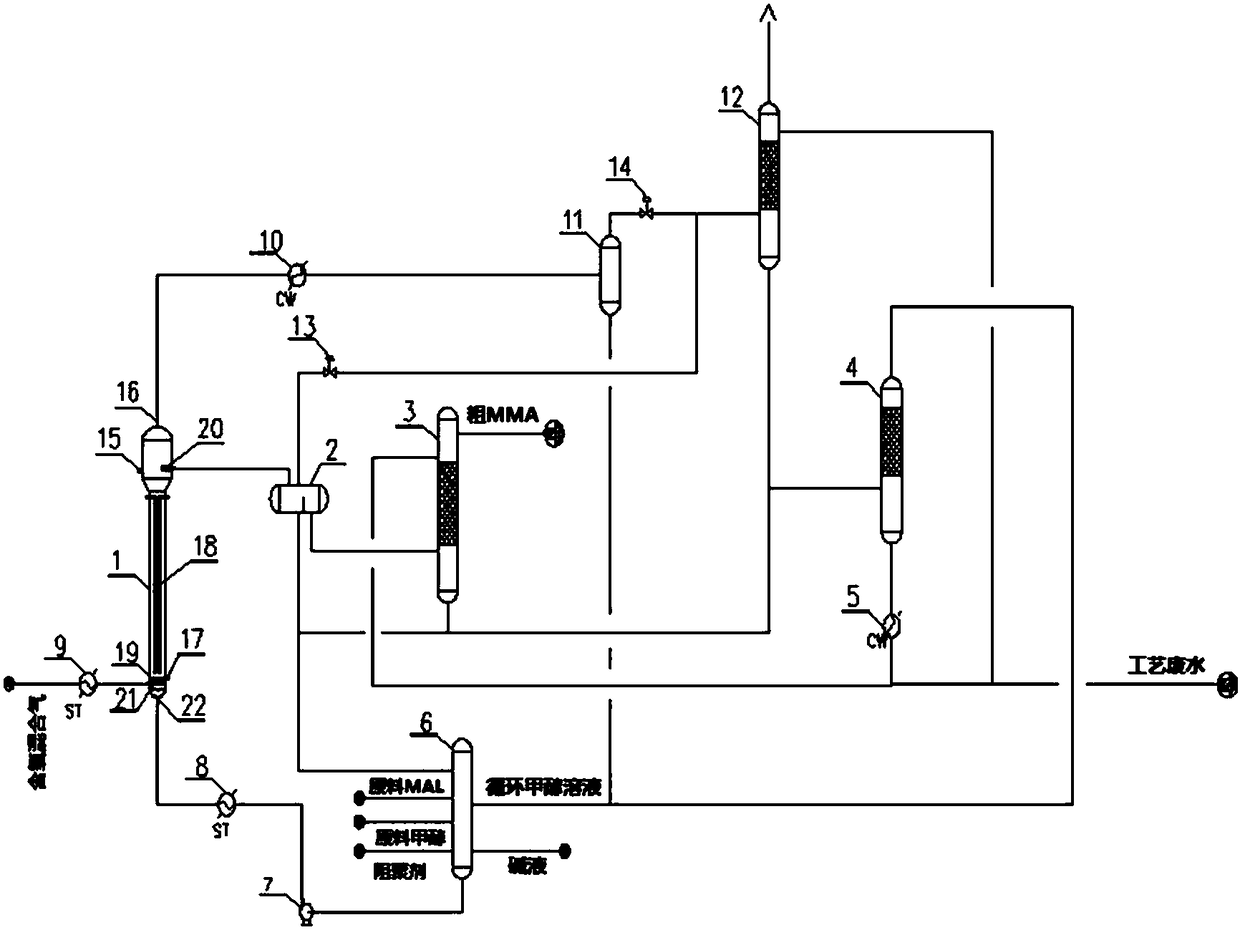

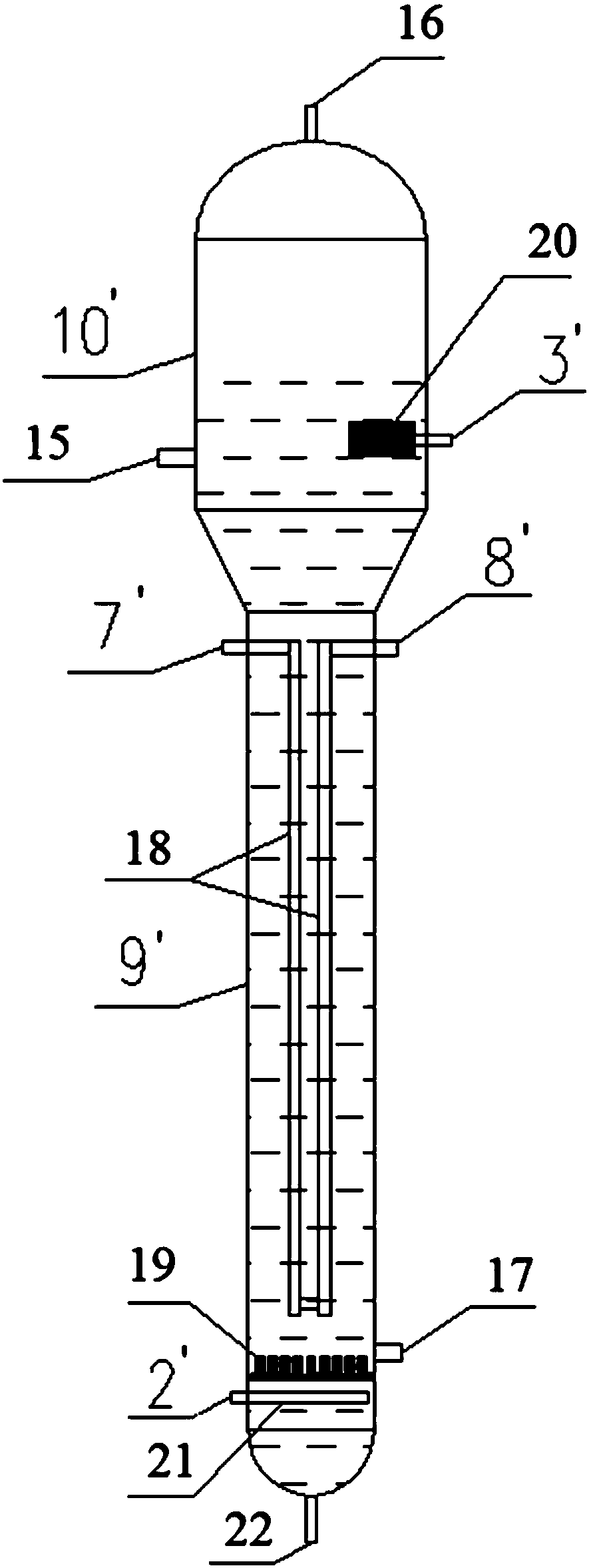

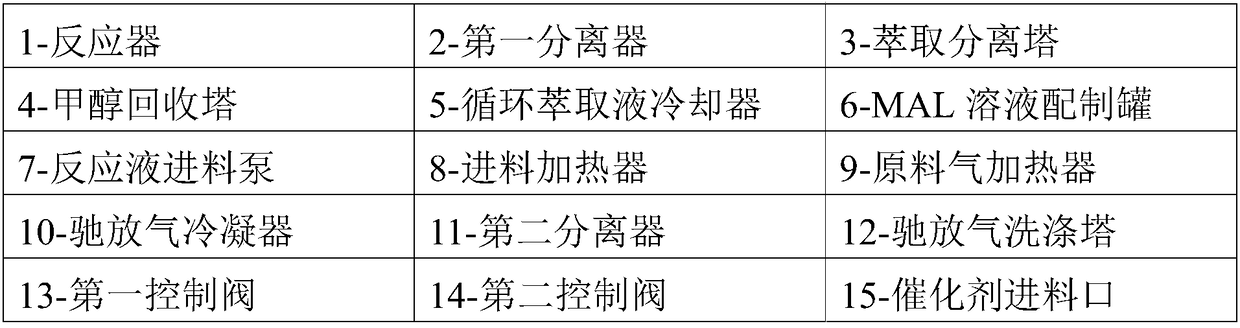

[0355] Embodiment 1 methyl methacrylate reaction device

[0356] Such as figure 1 As shown, the device includes a three-phase bubbling bed synthesis reactor, an inlet and outlet connection of the three-phase bubbling bed synthesis reactor, a first separator, an extraction separation tower, a raw material recovery tower, a circulating extract liquid cooler, and a raw material liquid preparation tank, reaction liquid feed pump, feed heater, feed gas heater, purge gas condenser, second separator, purge gas scrubber, first control valve, second control valve, catalyst feed port, Purge gas outlet, catalyst discharge port, heat extraction device, gas-liquid distributor, liquid extraction filter unit, gas distributor, liquid feed port;

[0357] The purge gas outlet of the three-phase bubbling bed synthesis reactor is connected with the purge gas condenser;

[0358] The liquid extraction filter unit of the three-phase bubbling bed synthesis reactor is connected with the first separa...

Embodiment 2

[0404] Adopt the reaction device (reaction system and separation method) that embodiment 1 provides, prepare methyl methacrylate at different reaction conditions with different feed conditions and catalyst content, carry out continuous separation test simultaneously, feed conditions and catalyst content are as follows Shown in Table 1, reaction conditions are shown in Table 2.

[0405] Described reaction system and separation method specifically include:

[0406] 1) Add a certain concentration of granular catalyst slurry (catalyst solid particle nano-gold 30% aqueous solution) into the reactor with deionized water to reach a liquid level of 80%;

[0407] 2) Feed nitrogen from the air feed line of the reactor to keep the catalyst in suspension in the reactor while establishing the reaction system pressure;

[0408] 3) add methanol in the extraction tower to establish a certain liquid level (80% liquid level);

[0409] 4) Add methanol aqueous solution to the methanol recovery ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com