Black phosphorene modified and fibroin filled porous composite gel material and preparation method thereof

A silk protein and composite gel technology, applied in the field of silk materials, can solve problems such as rare applications, and achieve the effects of improving mechanical properties and sensitivity, improving entanglement force, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

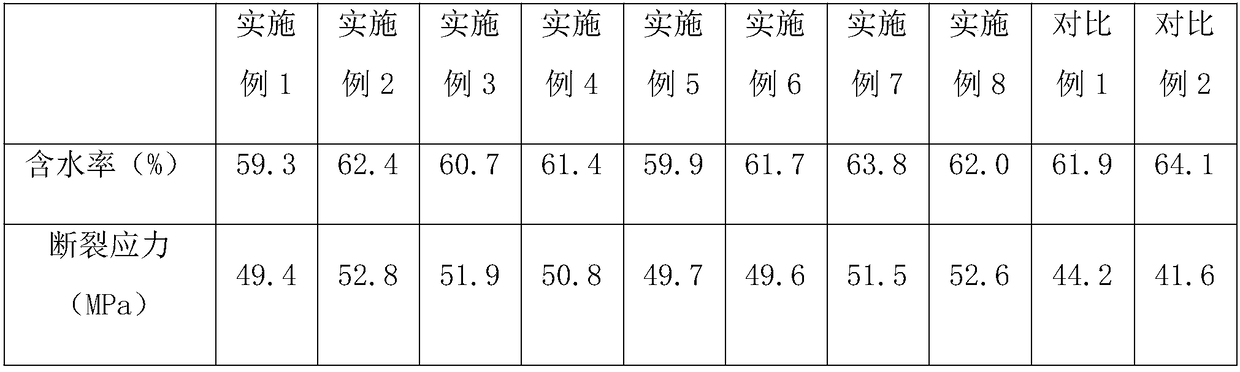

Examples

Embodiment 1

[0025] (1) According to the mass ratio of black phosphorene to silk protein of 1:20, add 1wt% black phosphorene solution into 5wt% silk protein solution and stir to obtain black phosphorene-modified silk protein solution.

[0026] (2) Put the fibroin solution modified by black phosphorene in a polytetrafluoroethylene mold, let it stand at 23°C for 2 days to dry to form a film, then add it to an aqueous solution containing 1% formic acid, and stir evenly to obtain a modified Phosphorene-modified silk protein solution.

[0027] (3) Insert the graphite rod positive electrode into the silk protein porous material with a pore size of 5 μm, place it in the modified black phosphorene-modified silk protein solution, insert the graphite rod negative electrode, and feed 15V as a constant voltage, electrogel treatment After 30 minutes, it was taken out to obtain a porous composite gel material filled with black phosphorene modified silk protein.

Embodiment 2

[0029] (1) According to the mass ratio of black phosphorene to silk protein of 1:50, add 3wt% black phosphorene solution into 10wt% silk protein solution and stir to obtain black phosphorene-modified silk protein solution.

[0030] (2) Put the fibroin solution modified by black phosphorene in a polytetrafluoroethylene mold, let it stand at 30°C for 7 days, dry it to form a film, then add it to an aqueous solution containing 5% formic acid, and stir evenly to obtain a modified Phosphorene-modified silk protein solution.

[0031] (3) Insert a graphite rod positive electrode into a porous carbon material with a pore size of 20 μm, place it in a modified black phosphorene-modified silk protein solution, insert a graphite rod negative electrode, feed 25V to a constant voltage, and conduct electrogel treatment for 240 minutes After that, it was taken out to obtain a porous composite gel material filled with black phosphorene modified silk protein.

Embodiment 3

[0033] (1) According to the mass ratio of black phosphorene to silk protein of 1:30, add 2wt% black phosphorene solution into 8wt% silk protein solution and stir to obtain black phosphorene-modified silk protein solution.

[0034] (2) Put the fibroin solution modified by black phosphorene in a polytetrafluoroethylene mould, let it stand for 5 days at 25°C and dry it to form a film, then add it to an aqueous solution containing 2% formic acid, and stir evenly to obtain a modified Phosphorene-modified silk protein solution.

[0035] (3) Insert graphite rod positive electrode into the cellulose porous material with a pore size of 10 μm, place it in the modified black phosphorene-modified silk protein solution, insert graphite rod negative electrode, feed 20V to be a constant voltage, and conduct electrogel treatment After 60 minutes, it was taken out to obtain a porous composite gel material filled with black phosphorene modified silk protein.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com