Static fermentation device and method and application thereof

A static fermentation and standing technology, which is applied in fermentation, microbial-based methods, biochemical cleaning devices, etc., can solve problems such as poor fermentation efficiency and fermentation effect, failure to meet production requirements, and poor mass transfer. Achieve good fermentation parameters, improve work efficiency, and meet the needs of cell fermentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

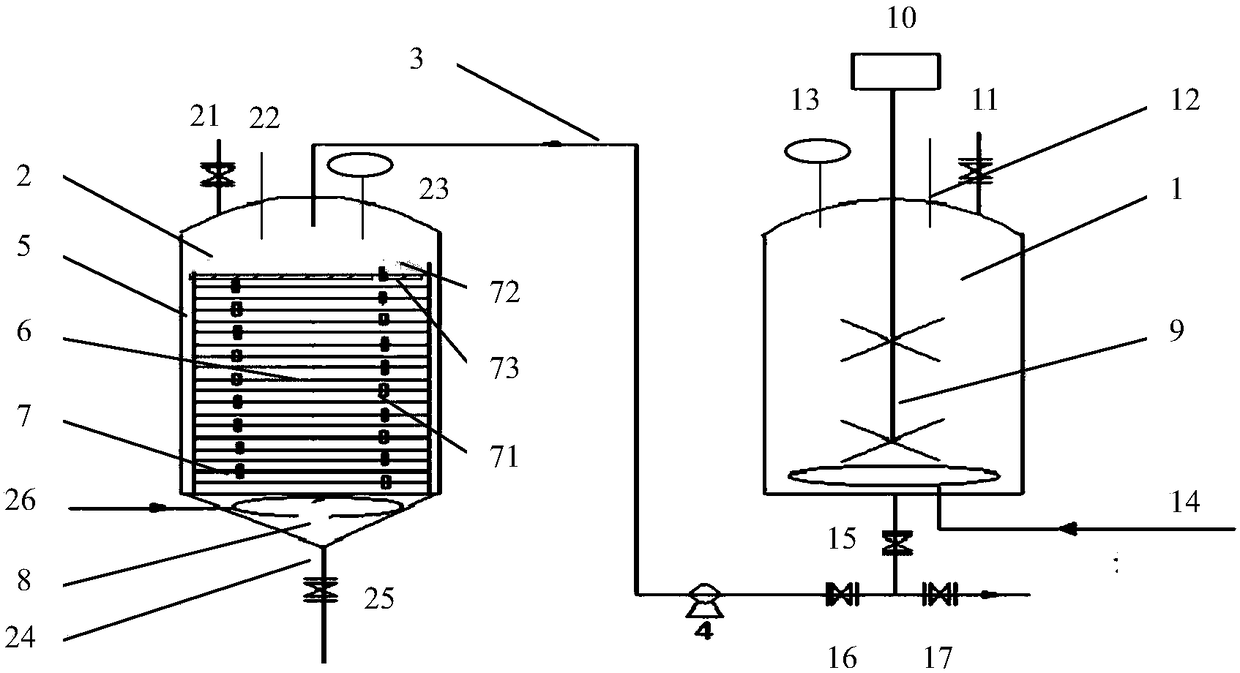

[0031] like figure 1 As shown, the device includes a stirring fermenter 1 and a stratified static reaction tank 2, which are connected by a feed pipe 3 and a pump 4 between the two tanks; the stratified static reaction tank 2 is provided with a tray support 5, and the tray support 5. Several trays 6 are placed from top to bottom, and the bottom of each tray 6 is provided with a sunken through-hole 7, and a height-adjustable drainage tube 71 is arranged in the through-hole 7, and the drainage tube 71 on each tray 6 is provided separately. The drainage tube 71 is a short hollow tube, and the material liquid in the upper tray is introduced into the lower tray through the drainage tube 71. In order to make there is no gap between the through hole 7 and the drainage tube 71, a leak-proof seal is fixed in the through hole 7 Ring, the horizontal distance between the drainage tubes 71 of the adjacent upper and lower trays 6 is 2 / 3 of the tray diameter, the tray 6 is selectively loaded...

Embodiment 2

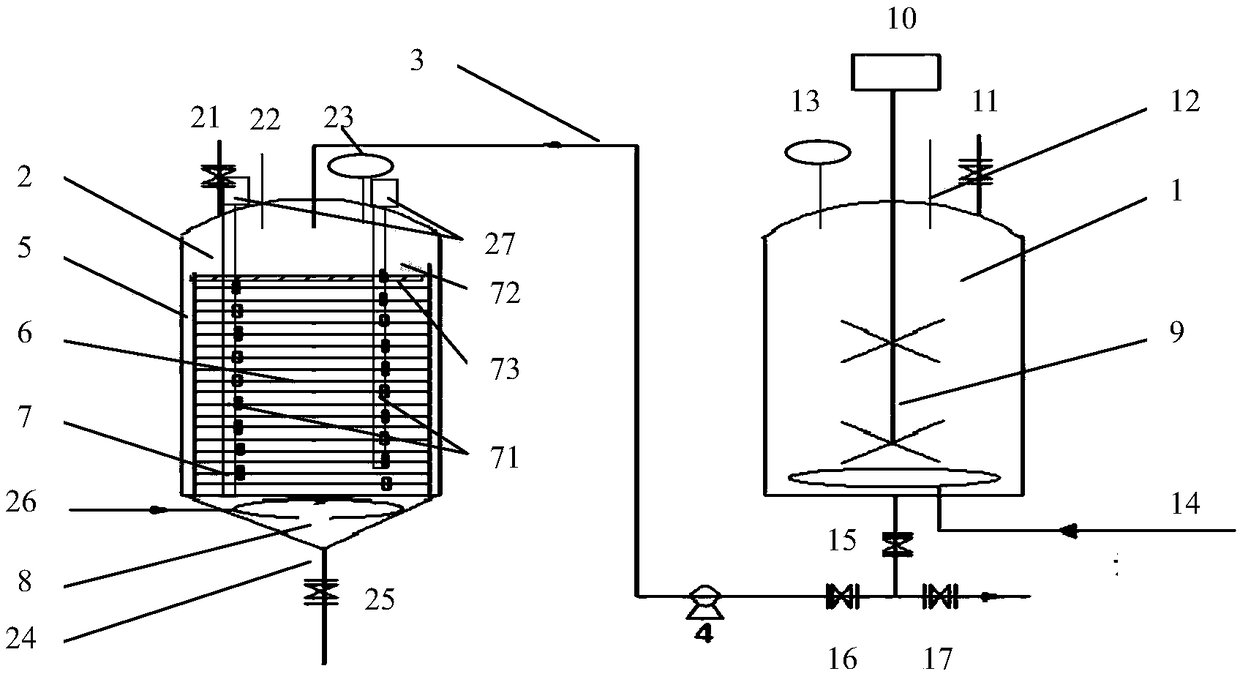

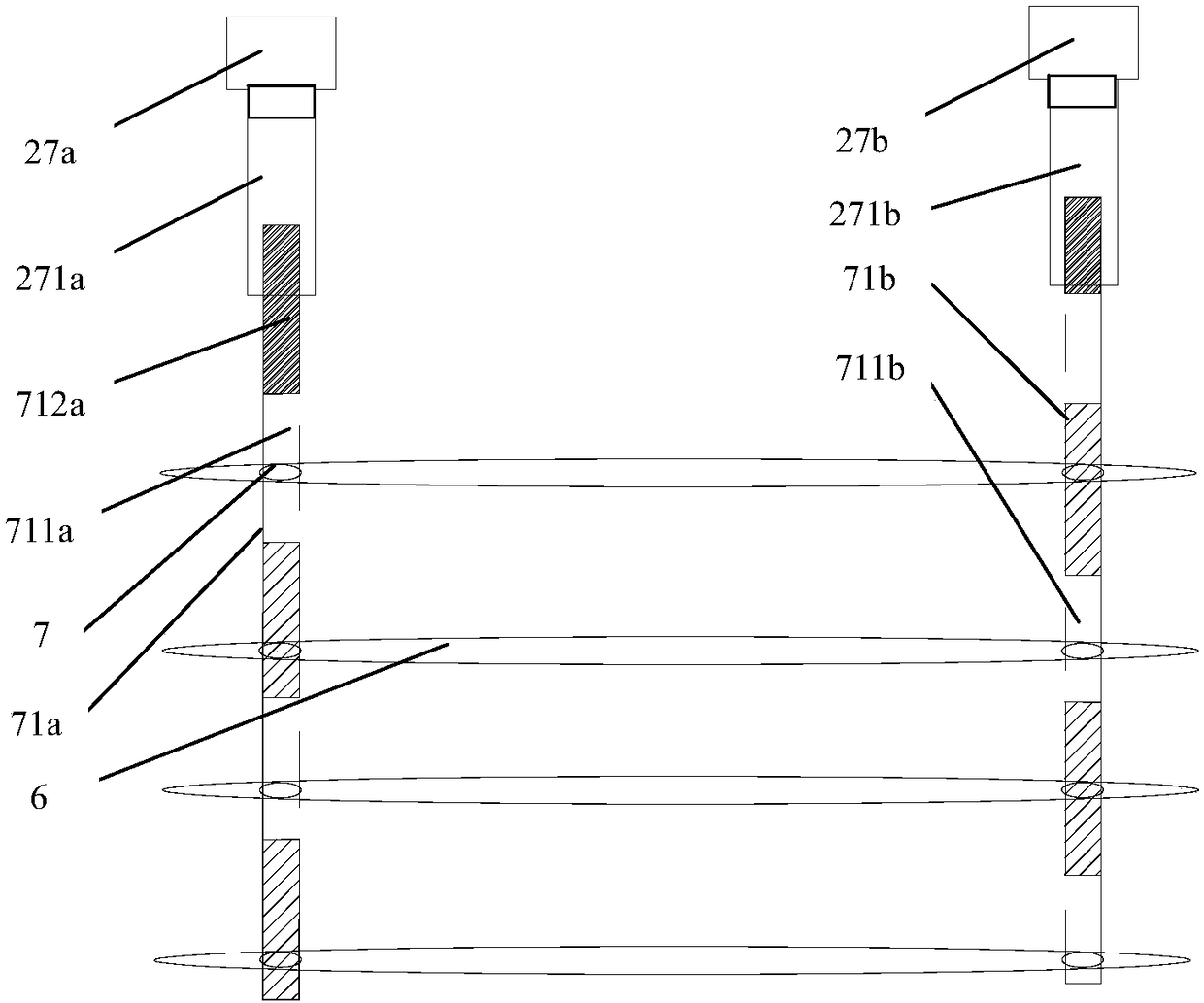

[0034] like figure 2 As shown, on the basis of Embodiment 1, the device sets the drainage tube 71 as a long vertical tube, and the horizontal distance between the two drainage tubes 71 is 2 / 3 of the diameter of the tray, and runs through all the trays 6 from top to bottom, respectively, to drain The pipe 71 is provided with a hollow section 711 and a solid section 712, the upper and lower side walls of the hollow section 711 have flow holes, the solid section at the top of the drainage pipe 71 is provided with external threads, and the left side drainage pipe 71a is threadedly connected to the drive motor 27a. The output shaft sleeve 271a and the right side drainage tube 71b are connected to the output shaft sleeve 271b of the drive motor 27b by threads, and the output shaft sleeves 271a and 271b are provided with internal threads. When the output shaft rotates, the drainage tube 71 is driven to move up and down by the thread. The driving motors 27a and 27b are respectively i...

Embodiment 3

[0038] Seed preservation and preparation: the strain is Acetobacter xylinum 700178, the medium used for the slant is YPD, stored at 4°C, and transferred once every two months. Scrape a ring of Acetobacter xylinum into a 1L Erlenmeyer flask containing 400mL seed medium (medium: glucose 50, yeast powder 5, peptone 5, unit g / L; sterilize at 121°C for 20 minutes), 80r / min , Culture at 28°C for 1 day;

[0039] Fermentation: After diluting the molasses by one time, adjust the pH to 2.0 with concentrated sulfuric acid, maintain at 70°C for 30 minutes, cool to room temperature, take the supernatant, dilute it 5 times, add yeast extract 10, peptone 10, ammonium sulfate 4, sulfuric acid Magnesium 2, disodium hydrogen phosphate 3, citric acid 1.8, lactic acid 0.5 (unit g / L), adjust the pH to 5.0, and sterilize at 121° C. for 20 minutes; after cooling, insert the shake flask seeds into Example 1 according to 8% inoculum In the 50-liter stirred fermenter 1 of the device, the temperature i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com