NDT Aerosol

A non-destructive testing, aerosol technology, used in material excitation analysis, fluorescence/phosphorescence, optical testing flaws/defects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

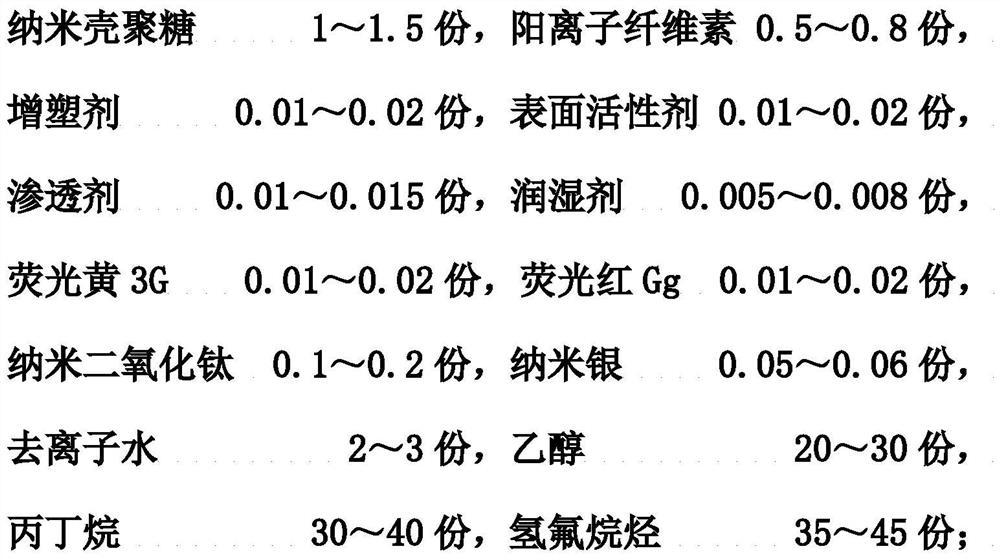

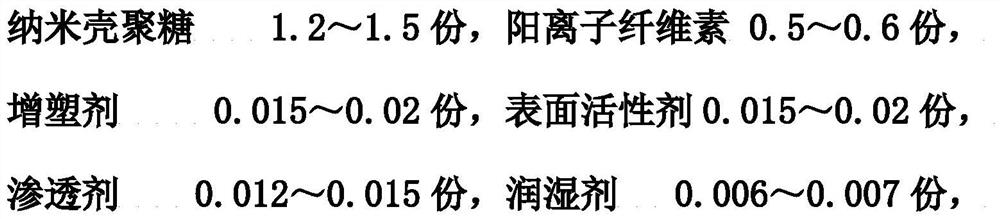

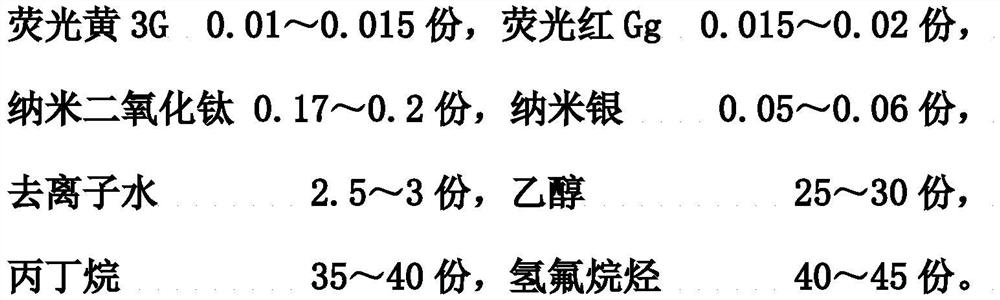

Method used

Image

Examples

Embodiment 1

[0029] 1) Prepare material A

[0030] Take 0.01 part of fluorescent yellow 3G, 0.02 part of fluorescent red Gg, 0.2 part of nano-titanium dioxide, 0.05 part of nano-silver, and 2.5 parts of deionized water, mix and stir evenly, and prepare material A for later use.

[0031] 2) Prepare material B

[0032] Add 30 parts of ethanol successively in the material A that makes, 1.2 parts of nano-chitosan, 0.5 part of cationic cellulose, 0.02 part of dimethyl phthalate (plasticizer), isomerism decanol polyoxyethylene ether ( Surfactant) 0.017 part, fatty alcohol polyoxyethylene ether (penetrating agent) 0.014 part, silanol nonionic surfactant (wetting agent) 0.007 part, stir well, and prepare material B for later use.

[0033] 3) Preparation of flaw detection agent

[0034] The prepared material B is equally divided into aerosol cans, and the aerosol valve is assembled, and then 40 parts of propane butane and 45 parts of hydrofluoroalkane are equally divided into each aerosol can to pr...

Embodiment 2

[0036] The difference from Example 1 is that in this example, the proportioning ratio of each raw material component is shown in Table 1.

[0037] Table 1

[0038] components Dosage (parts) nano chitosan 1 cationic cellulose 0.5 Dimethyl phthalate 0.01 Isomerized Decyl Alcohol Polyoxyethylene Ether 0.01 Fatty alcohol polyoxyethylene ether 0.01 Silanol Nonionic Surfactant 0.005 Fluorescent Yellow 3G 0.01 Fluorescent red Gg 0.01 Nano Titanium Dioxide 0.1 nano silver 0.05 Deionized water 2 ethanol 20 propane 30 Hydrofluoroalkane 35

Embodiment 3

[0040] The difference from Example 1 is that in this example, the proportioning ratio of each raw material component required to prepare the flaw detection aerosol is shown in Table 2.

[0041] Table 2

[0042] components Dosage (parts) nano chitosan 1.5 cationic cellulose 0.8 Dimethyl phthalate 0.02 Isomerized Decyl Alcohol Polyoxyethylene Ether 0.02 Fatty alcohol polyoxyethylene ether 0.015 Silanol Nonionic Surfactant 0.008 Fluorescent Yellow 3G 0.02 Fluorescent red Gg 0.02 Nano Titanium Dioxide 0.2 nano silver 0.06 Deionized water 3 ethanol 30 propane 40 Hydrofluoroalkane 45

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com