Nb-Rh co-doped titanium dioxide nanorod photocatalyst, and preparation method and application thereof

A photocatalyst and titanium dioxide technology, which is applied in the field of photocatalytic materials, achieves the effects of simple preparation method, easy large-scale commercial production, and improved photocatalytic hydrogen production activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0069] Niobium pentachloride and rhodium trichloride hydrate with a rhodium content of 40% were dissolved in ethanol respectively to prepare 0.05M niobium pentachloride ethanol solution and 0.01M rhodium trichloride ethanol solution.

Embodiment 1

[0071] About 1mL of hydrochloric acid, 0.13mL of the 0.05M niobium pentachloride prepared in the above preparation example 1, 1mL of the 0.01M rhodium trichloride prepared in the above preparation example 1 and 3.4g of butyl titanate were added to 20mL of anhydrous In the ethanol solution, stir to accelerate the dissolution and form a transparent solution, then add 3-5mL of high-purity water, and continue stirring until a gel is formed. The gel was poured into 10M NaOH solution and stirred to disperse, filtered and redispersed into 10M NaOH solution, and then hydrothermally reacted at 150°C for 100h. The cooled product was washed several times with pure water, dilute nitric acid, pure water, and absolute ethanol in sequence, then dried in an oven at 70°C for 20 hours, and then put into a muffle furnace for calcination at 450°C for 4 hours to obtain Nb-Rh co-doped Doped TiO 2 Nanorods - Ti 0.999 Nb 0.0005 Rh 0.0005 o 2 Nano stave.

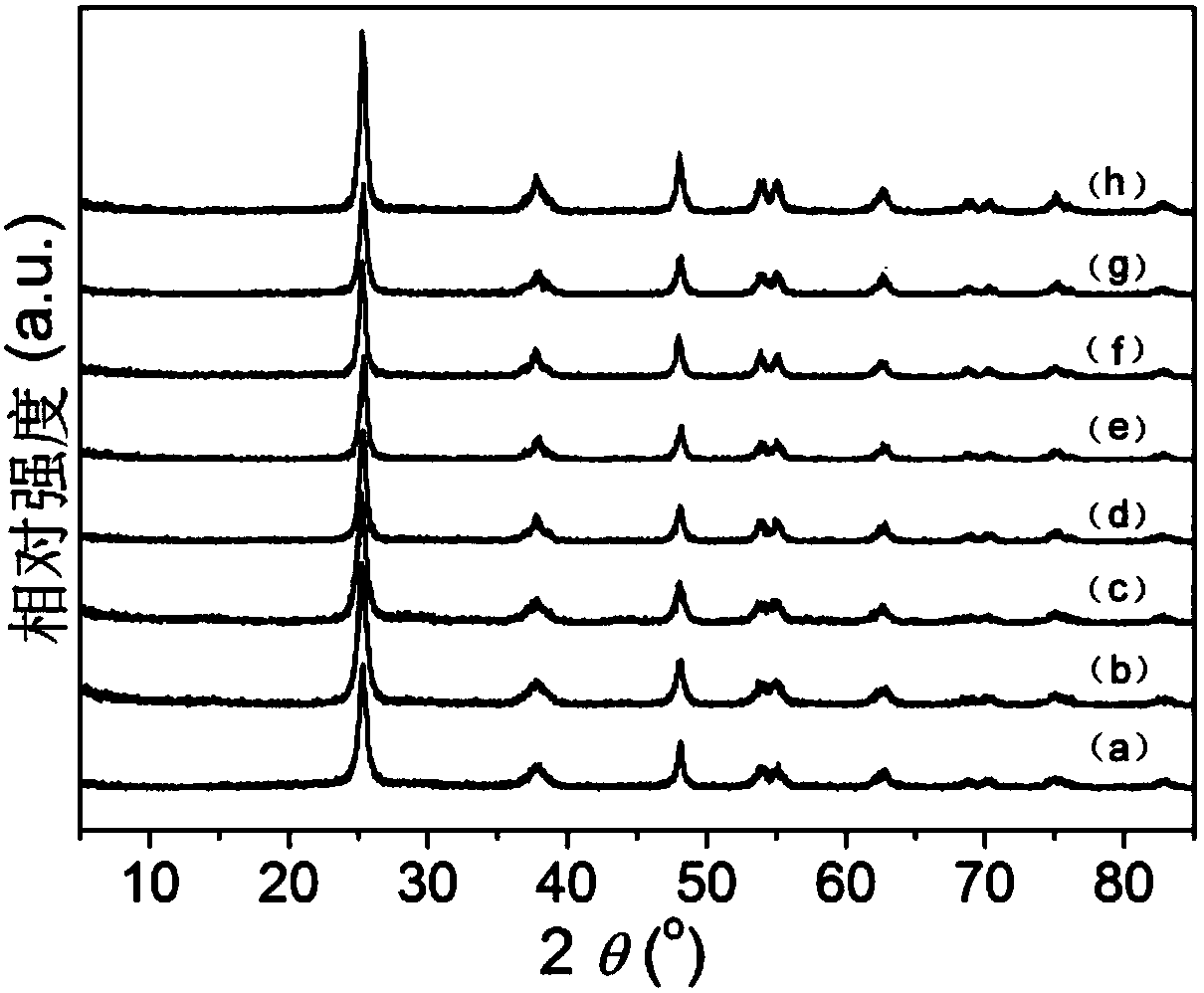

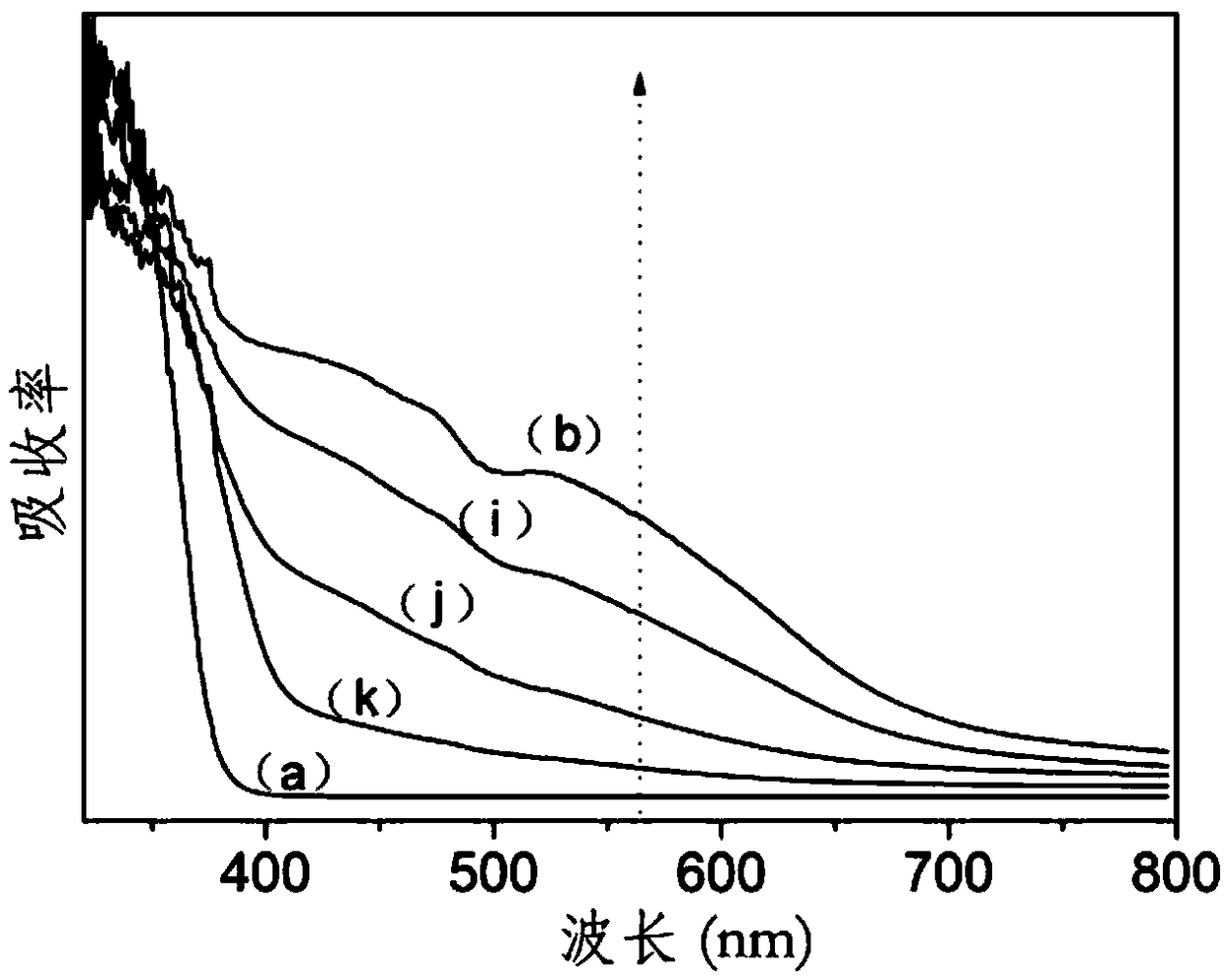

[0072] The results show that: the Nb-Rh...

Embodiment 2

[0075] About 1mL of hydrochloric acid, 0.13mL of the 0.05M niobium pentachloride prepared in the above preparation example 1, 10mL of the 0.01M rhodium trichloride prepared in the above preparation example 1 and 3.4g of butyl titanate were added to 20mL of anhydrous In the ethanol solution, stir to accelerate the dissolution and form a transparent solution, then add 3-5mL of high-purity water, and continue stirring until a gel is formed. The gel was poured into 10M NaOH solution and stirred to disperse, filtered and redispersed into 10M NaOH solution, and then hydrothermally reacted at 150°C for 100h. The cooled product was washed several times with pure water, dilute nitric acid, pure water, and absolute ethanol in sequence, then dried in an oven at 70°C for 20 hours, and then put into a muffle furnace for calcination at 450°C for 4 hours to obtain Nb-Rh co-doped Doped TiO 2 Nanorods - Ti 0.99 Nb 0.0005 Rh 0.0095 o 2 Nano stave.

[0076] The results show that: the Nb-Rh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com