Preparation method of functionalized two-dimensional nano-material and functionalized nano thin film

A two-dimensional nanomaterial and two-dimensional nanotechnology, applied in the field of nanomaterial preparation, can solve problems such as the limitation of functionalized two-dimensional nanomaterials, the distance between industrial production and application, and achieve good environmental protection, low cost, and high quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The purpose of this example is to verify the preparation of hydroxyl (OH) functional group-functionalized hexagonal boron nitride nanosheets using the method of the present invention.

[0051] In this example, hexagonal boron nitride and sucrose are mixed in a mass ratio of 1:60 and put into a ball mill jar. For ball milling, stainless steel balls with a diameter of 10mm were used, and the ball milling condition was 700rmp, and ball milling was carried out at room temperature for 20 hours. High-speed stainless steel balls provide enough energy to effectively strip boron nitride raw materials. Among them, sucrose is not only an effective stripping agent, but also protects the structure of boron nitride from being destroyed by mechanical force during the stripping process to form lattice defects.

[0052] After ball milling, the obtained mixed powder is dissolved in deionized water, and its aqueous solution is placed in a dialysis membrane and washed repeatedly for 5-10 ...

Embodiment 2

[0057] The purpose of this embodiment is to verify that amino (NH 2 ) functionalized hexagonal boron nitride nanosheets.

[0058] In this example, hexagonal boron nitride and urea were mixed in a mass ratio of 1:10 and then put into a stainless steel ball mill jar. Stainless steel balls with a diameter of 10 mm were used for ball milling, the ball milling condition was 500 rpm, and the ball milling was carried out at room temperature for 30 hours. Its principle is identical with embodiment 1.

[0059] After the ball milling is finished, the obtained mixed powder is dissolved in deionized water, and the aqueous solution is put into the dialysis membrane and washed repeatedly for 5-10 days to completely remove the urea. Finally, a stable colloidal solution of amino-functionalized hexagonal boron nitride can be obtained.

[0060] Figure 10 and Figure 11 It is the observation result of the morphology of the two-dimensional material prepared in this example by scanning elect...

Embodiment 3

[0062] The purpose of this example is to verify the preparation of hydroxyl (OH) functional group-functionalized molybdenum sulfide nanosheets using the method of the present invention.

[0063]In this example, molybdenum sulfide and glucose were mixed in a mass ratio of 1:50 and then put into a stainless steel ball mill jar. For ball milling, stainless steel balls with a diameter of 10mm were used, the ball milling condition was 500rmp, and ball milling was performed at room temperature for 5 hours. The mixed powder obtained after ball milling is dissolved in deionized water, and its aqueous solution is placed in a dialysis membrane and washed repeatedly for 5-10 days to completely remove glucose. Finally, a stable colloidal solution of hydroxyl (OH) functionalized molybdenum sulfide nanosheets was obtained.

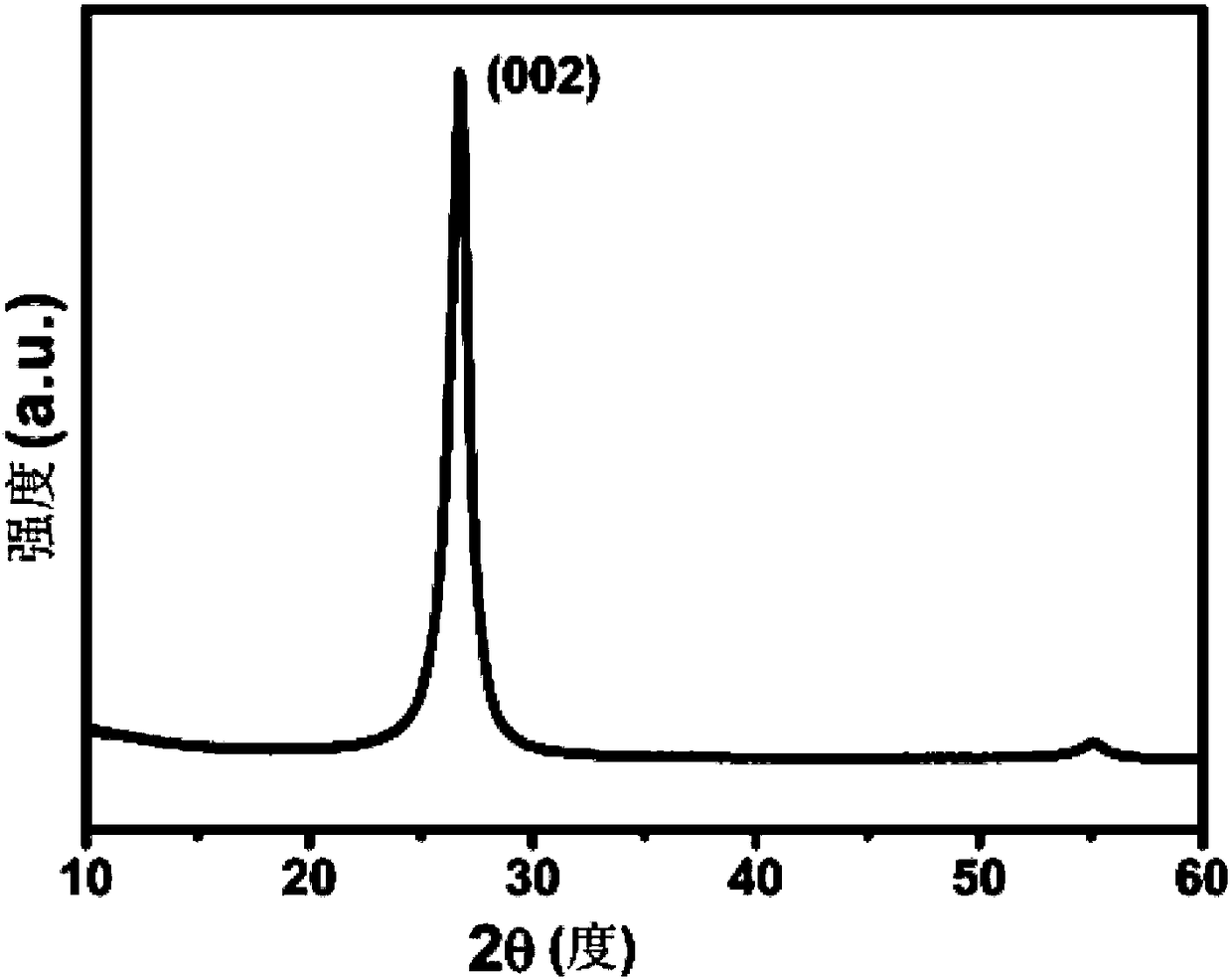

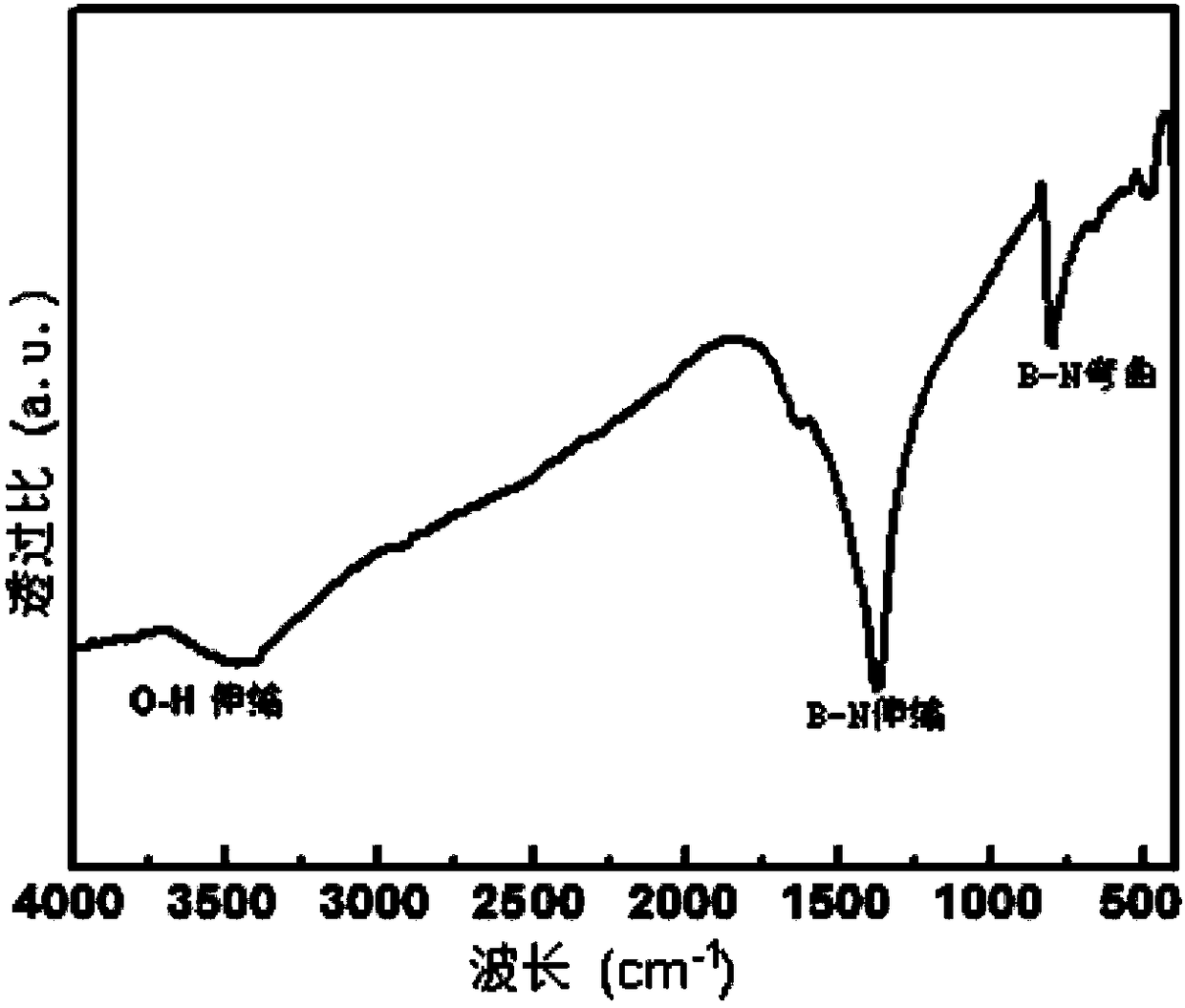

[0064] Figure 12 is the XRD pattern of functionalized molybdenum sulfide nanoflakes. From the results in the figure, it can be confirmed that the substance in the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com