Extracting and separating method of magnolol and honokiol

A technology of honokiol and honokiol, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems that honokiol and honokiol products have no mature technology reports and other problems , to achieve the effect of broadening the application field of the product, low extraction temperature, and clean and tidy operating environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

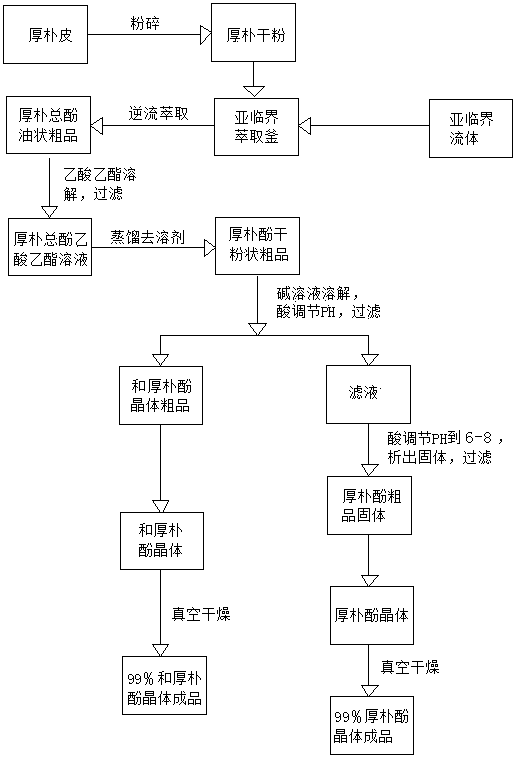

[0033] Embodiment one, such as figure 1 Shown, a kind of magnolol and the method for honokiol extraction and separation comprise the steps:

[0034] 1). One or more kinds of magnolia bark, root bark, branches and leaves are mixed and crushed into short filaments, and then pressed into tablets;

[0035] 2). Feed into the extraction kettle of subcritical equipment, pour into subcritical fluid (can contain entrainer);

[0036] 3). Control the pressure and temperature for countercurrent extraction and decompression separation, and repeat the extraction and separation operation to obtain Magnolia officinalis extract;

[0037] 4). Use ethyl acetate to dissolve Magnolia officinalis extract, filter the insoluble matter to obtain the solution, distill and recover the solvent, and obtain the crude product of light yellow crystal;

[0038] 5). Add alkali solution to the crude product, stir to dissolve, add organic weak acid to adjust the pH value to 9-11, honokiol crystals are precipit...

Embodiment 2

[0050] Example 2: 20 kg of Magnolia officinalis root bark is crushed into filaments, fed into tablets after processing, with a bulk density of 244 g / L; butane is used as the extraction agent, 0.4-0.5 MPa, 38-41 ° C countercurrent extraction twice. One hour at a time. The extract of Magnolia officinalis is obtained after evaporating the solvent in the separation tank. Take 0.5Kg of the crude product and dissolve it in 1000ml of ethyl acetate, filter to remove insoluble matter, and rotary evaporate the filtrate to obtain 480g of light yellow crystals. Add it into a 0.2% aqueous solution made of 250g potassium hydroxide, stir until it is completely dissolved, add 15% acetic acid dropwise to adjust the pH to 10.9, and a large amount of solids are precipitated. Filter to obtain 200g 90% honokiol crude product, repeat the above alkali-dissolving acid precipitation operation and then vacuum dry to obtain 198 grams of 99% honokiol.

[0051] Filtrate continues to adjust PH=7 with 15%...

Embodiment 3

[0052]Embodiment three, 20kg Magnolia officinalis root bark is crushed into filaments, fed after tableting treatment, bulk density is 200g / L; dimethyl ether is used as extraction agent, 4% (mass fraction) alcohol is put into kettle together as entraining agent, 0.4 -0.5MPa, 38-41°C countercurrent extraction twice, each time for one hour. The extract of Magnolia officinalis is obtained after evaporating the solvent in the separation kettle. Take 0.68Kg of the crude product and dissolve it in 1000ml of ethyl acetate, filter to remove the insoluble matter, and rotary evaporate the filtrate to obtain 620g of light yellow crystals. Add it into a 0.2% aqueous solution made of 380g of sodium hydroxide, stir until it is completely dissolved, add 15% acetic acid dropwise to adjust the pH to 11, and a large amount of solids are precipitated. Filtrate to obtain 350 g of 90% honokiol crude product, repeat the above operation of alkali dissolution and acid precipitation, and vacuum dry to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com