High-performance methanol engine fuel

A methanol engine, high-performance technology, applied in the field of methanol engine fuel and high-performance methanol engine fuel, can solve the problems of low calorific value of methanol fuel, hindering the normal use and popularization of methanol fuel, and achieve enhanced stability and easy ignition , Good combustion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

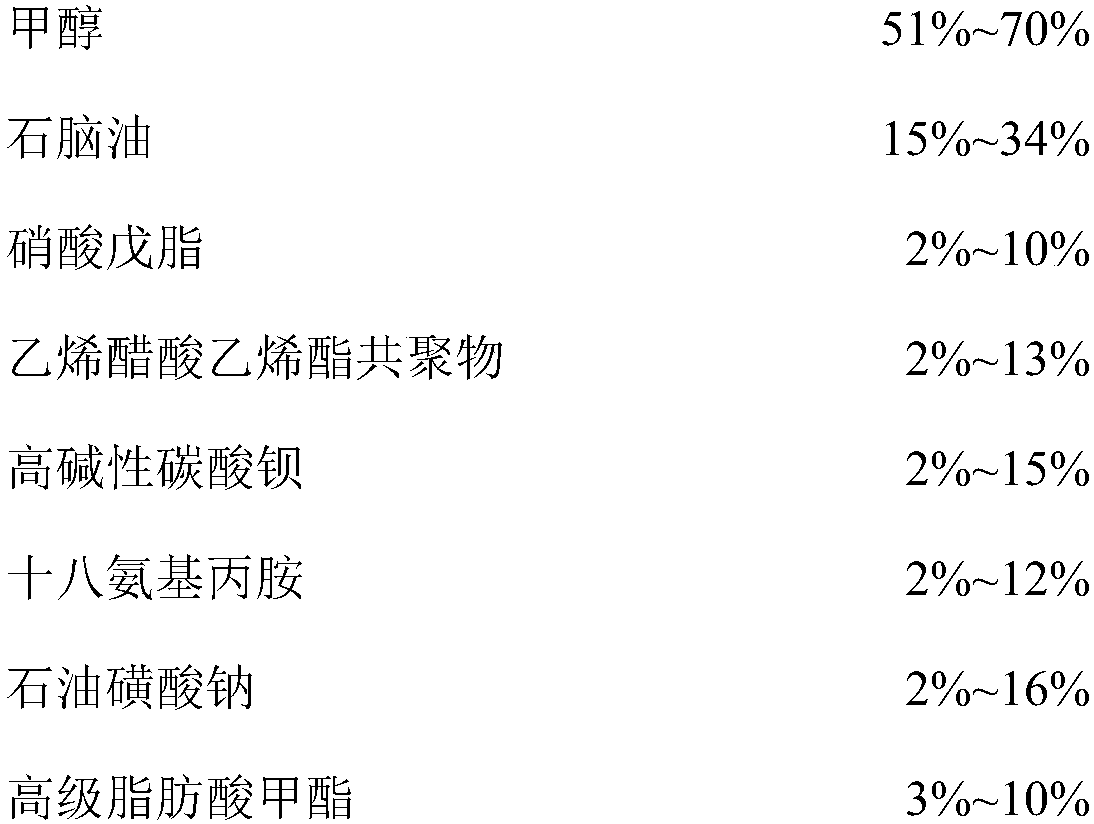

[0013] A kind of high-performance methanol engine fuel, its composition and weight percent are as follows:

[0014]

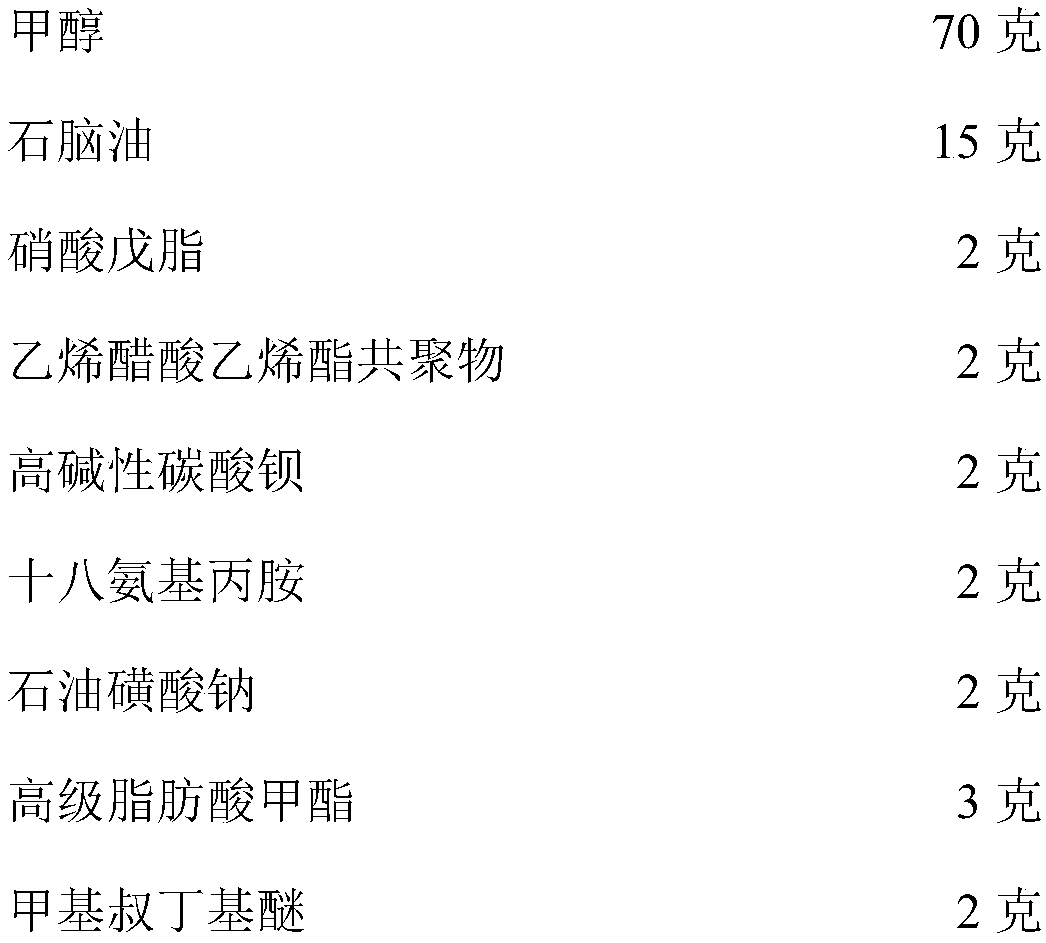

[0015] A kind of high-performance methanol engine fuel of the present invention, its preparation method is: first add 2 gram pentyl nitrates, 2 gram ethylene vinyl acetate copolymers, 2 gram perbasic barium carbonate, 2 gram octadecyl amino in reaction kettle Propylamine, 2 grams of petroleum sodium sulfonate, 3 grams of higher fatty acid methyl esters, and 2 grams of methyl tert-butyl ether were stirred, and stirred for 15 minutes and stirred uniformly to obtain 15 grams of total additives; get 15 grams of naphtha, add Enter in the reactor of 15 grams of total additives and continue to stir for 13 minutes, then slowly pour 70 grams of methyl alcohol into this reactor, stir for 20 minutes, and stir until the transparent liquid, this transparent liquid is the product of the present invention , it will not delaminate if it is placed for more than two years, an...

Embodiment 2

[0017] A kind of high-performance methanol engine fuel, its composition and weight percent are as follows:

[0018]

[0019] A high-performance methanol engine fuel, the preparation method of which is consistent with that described in Example 1.

Embodiment 3

[0021] A kind of high-performance methanol engine fuel, its composition and weight percent are as follows:

[0022]

[0023] A high-performance methanol engine fuel, the preparation method of which is consistent with that described in Example 1.

[0024] The product of the present invention is a transparent liquid, and its state is very stable. Compared with ordinary methanol used in engines, its calorific value and various technical performances are far superior to ordinary methanol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com