Inferior heavy oil fluidization conversion technology

A low-quality heavy oil and process technology, which is applied in the petroleum industry, granular/powdered fuel gasification, and the manufacture of combustible gas, etc., can solve the problems of large equipment investment and complicated operation, and achieve low investment, increase yield, save equipment and The effect of heating furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

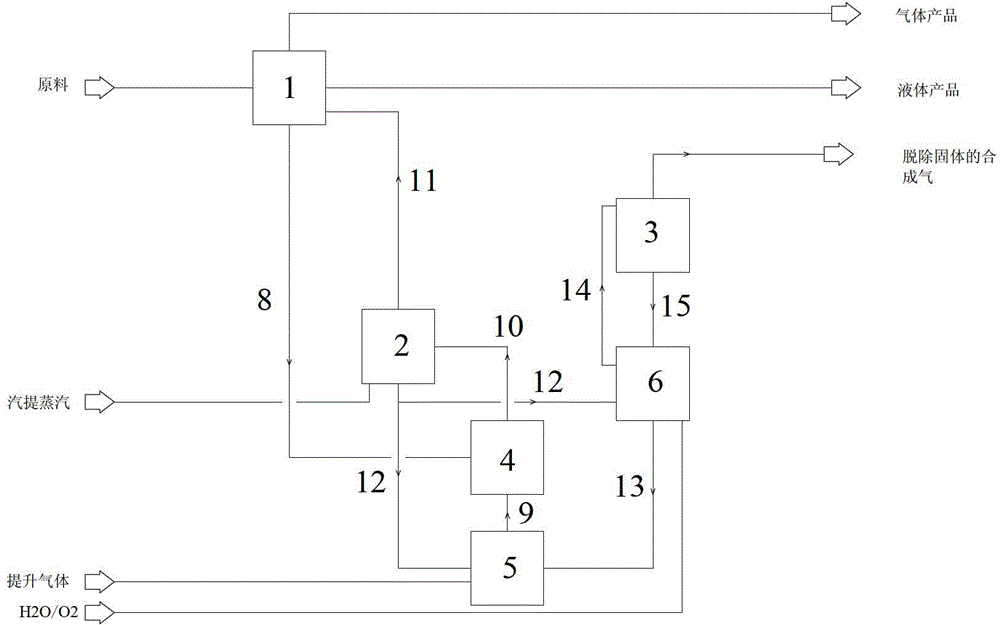

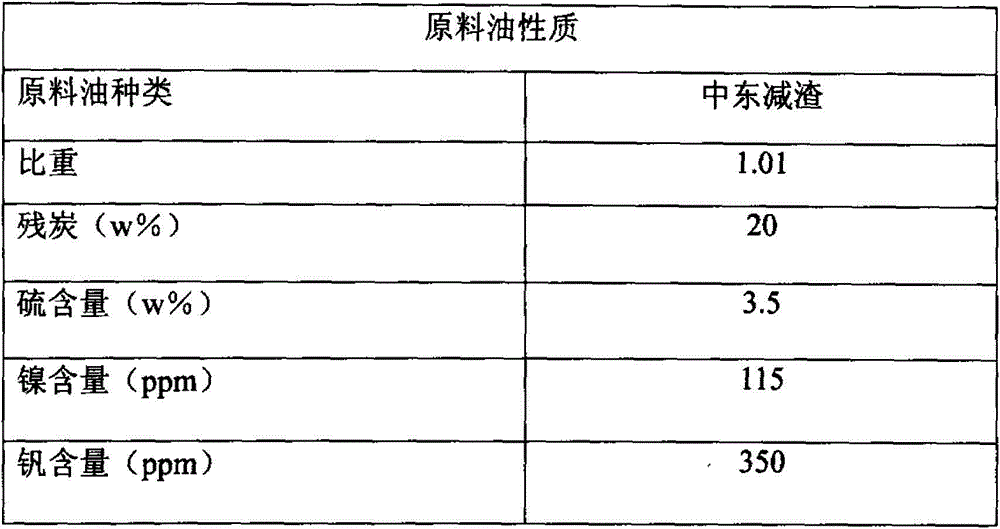

[0043] A fluidized conversion process for inferior heavy oil, its process flow is as follows figure 1 shown, including the following steps:

[0044] (1) The raw material oil (see Table 2 for properties) from the outside enters the lower part of the fractionation tower 1, contacts with the high-temperature reaction oil gas, separates the light components, and washes off the coke carrier and heavy components entrained in the reaction oil gas , and heated to 350°C to 400°C at the same time. After washing, the reaction oil gas enters the upper part of the fractionation tower 1 and is divided into gas and liquid products with different distillation ranges, such as dry gas, liquefied gas, gasoline fraction, diesel fraction, etc. And sent to the follow-up unit for further processing. Use the product fractionation tower to pretreat heavy raw materials, separate out the light components, and heat them, which saves equipment and heating furnaces for pretreatment of heavy oil raw materi...

Embodiment 2

[0060] Adopt the raw material and technological process identical with embodiment 1, riser reactor operating condition and product distribution are shown in Table 5:

[0061] table 5

[0062]

[0063]

[0064] The operating conditions and product distribution of the gasification reactor are shown in Table 6:

[0065] Table 6

[0066]

Embodiment 3

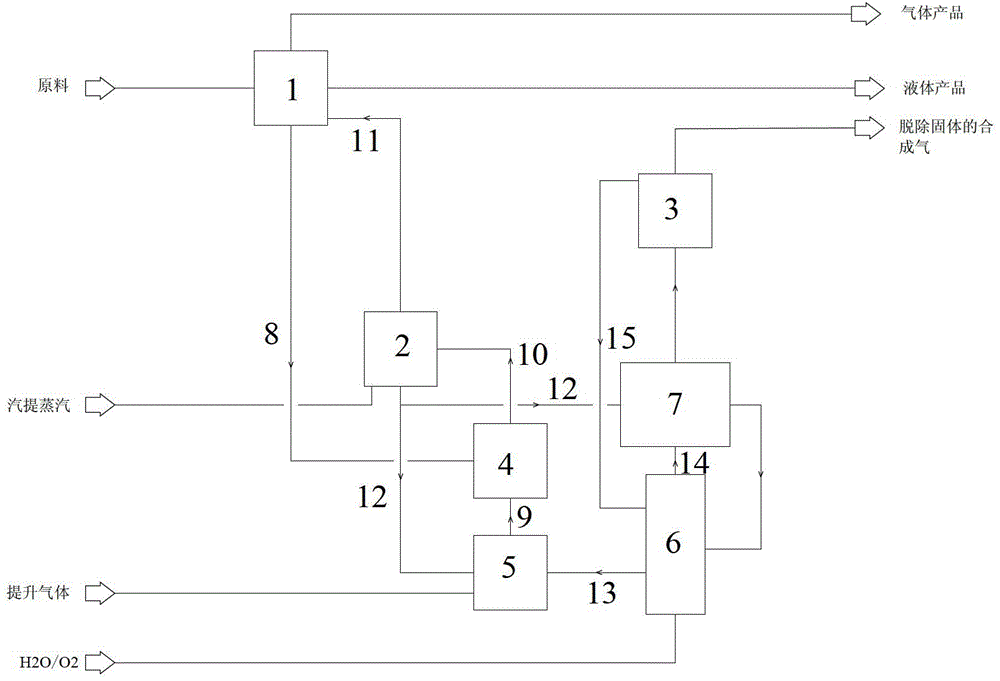

[0068] See figure 2 , the process flow is similar to that of Example 1, the difference is that in Example 3, a preheater 7 is added, which mainly plays a heating role. Preheating, while reducing the temperature of the high-temperature syngas 14, improves the operating conditions of the second gas-solid separation device 3. The operating conditions and product distribution of the gasification reactor in Example 3 are shown in Table 7.

[0069] Table 7

[0070]

[0071]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com