Styrene-acrylic antibacterial interior wall coating and preparation method thereof

An interior wall coating, styrene-acrylic technology, applied in antifouling/underwater coatings, coatings, paints containing biocides, etc. problems, to achieve the effects of excellent physical and chemical properties, improved construction performance, environmental protection and energy saving performance, and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

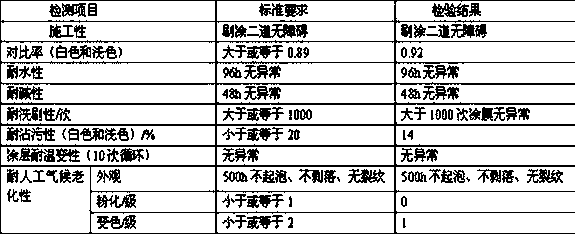

Examples

Embodiment 1

[0026] A styrene-acrylic antibacterial interior wall paint, its raw materials include the following components by weight: 20 parts of styrene-acrylic emulsion, 6 parts of nano-titanium dioxide slurry, 4 parts of antibacterial nano-titanium dioxide, 1 part of ultrafine aluminum carbonate, 8 parts of calcined kaolin, 10 parts of titanium dioxide, 10 parts of heavy calcium carbonate, 4 parts of talc, 1 part of dispersant, 0.2 part of defoamer, 0.1 part of wetting agent, 1.0 part of film-forming aid, 0.5 part of thickener, 1 part of antifreeze 0.1 part of pH regulator, 12 parts of deionized water.

[0027] The titanium dioxide rutile type titanium dioxide.

[0028] Described talcum powder is the pulvis that passes 500 mesh sieves.

[0029] The dispersant sodium tripolyphosphate.

[0030] Described defoamer is silicone defoamer.

[0031] Described coalescent is Texanol.

[0032] Described thickening agent is methyl cellulose.

[0033] Described antifreeze is ethylene glycol. ...

Embodiment 2

[0040] A styrene-acrylic antibacterial interior wall paint, its raw materials include the following components by weight: 40 parts of styrene-acrylic emulsion, 10 parts of nano-titanium dioxide slurry, 6 parts of antibacterial nano-titanium dioxide, 3 parts of ultrafine aluminum carbonate, 16 parts of calcined kaolin, 20 parts of titanium dioxide, 20 parts of heavy calcium carbonate, 6 parts of talc, 2 parts of dispersant, 0.5 part of defoamer, 0.3 part of wetting agent, 2.5 parts of film-forming aid, 0.9 part of thickener, 2 parts of antifreeze part, 0.2 part of pH regulator, and 20 parts of deionized water.

[0041] The titanium dioxide rutile type titanium dioxide.

[0042] Described talcum powder is the pulvis that passes 1000 mesh sieves.

[0043] The dispersant sodium tripolyphosphate.

[0044] Described defoamer is mineral oil defoamer.

[0045] Described coalescent is Texanol.

[0046] Described thickening agent is hydroxypropyl methylcellulose.

[0047] Described...

Embodiment 3

[0054] A styrene-acrylic antibacterial interior wall paint, its raw materials include the following components by weight: 35 parts of styrene-acrylic emulsion, 8 parts of nano-titanium dioxide slurry, 5 parts of antibacterial nano-titanium dioxide, 2 parts of ultrafine aluminum carbonate, 12 parts of calcined kaolin, 15 parts of titanium dioxide, 15 parts of heavy calcium carbonate, 5 parts of talc, 1.5 parts of dispersant, 0.4 parts of defoamer, 0.2 parts of wetting agent, 1.5 parts of film-forming aid, 0.6 parts of thickener, 1.5 parts of antifreeze parts, 0.15 parts of pH regulator, and 16 parts of deionized water.

[0055] The titanium dioxide rutile type titanium dioxide.

[0056] Described talcum powder is the pulvis that passes 600 mesh sieves.

[0057] The dispersant sodium tripolyphosphate.

[0058] The defoamer is a combination of a silicone defoamer and a mineral oil defoamer in any proportion.

[0059] Described coalescent is Texanol.

[0060] The thickener is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com