Composite modified waterborne polyurethane synthetic leather

A water-based polyurethane and composite modification technology, which is applied in textiles and papermaking, can solve the problems of comparable comprehensive performance, performance reduction, and small molecular weight, and achieve the effects of improving kneading resistance, improving elasticity, and increasing crosslinking density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

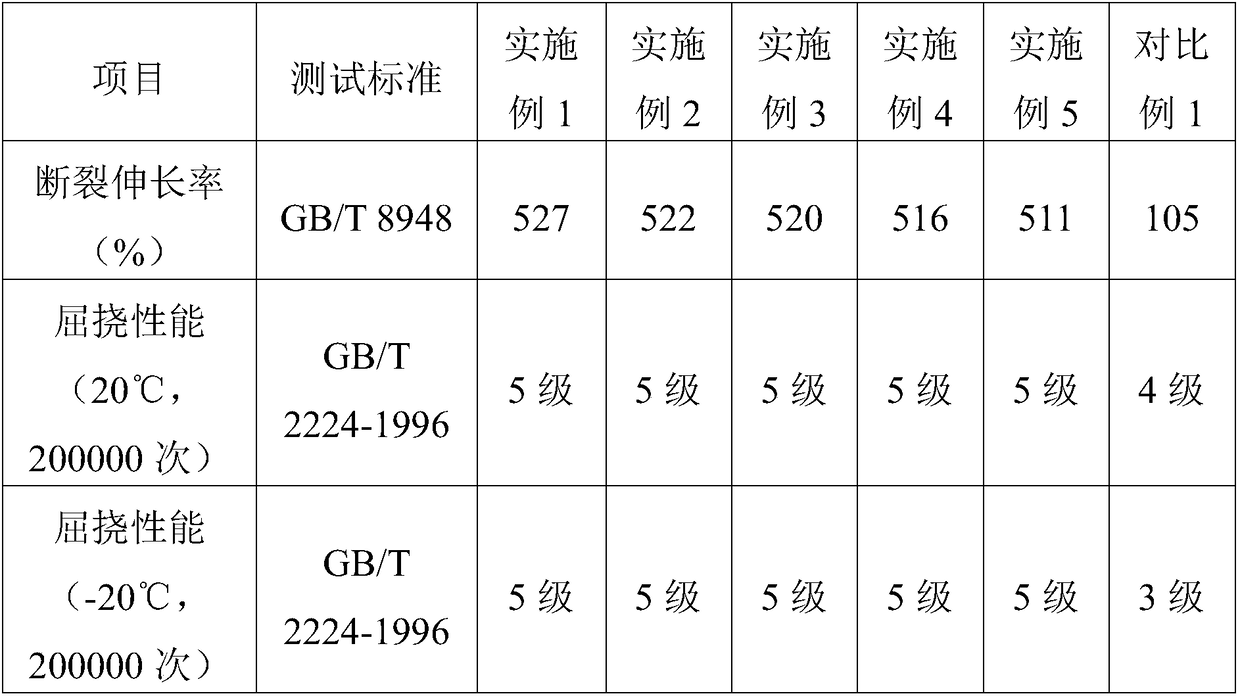

Examples

Embodiment 1

[0036] A water-based polyurethane emulsion, comprising the following raw material components:

[0037] 100 parts of isophorone diisocyanate, 250 parts of polytetrahydrofuran diol, 16 parts of 1,4-butanediol, 6 parts of water-based epoxy resin emulsion (WS-500, purchased from Xinhua New Material Technology Co., Ltd.), 3 3 parts of methylolpropane, 8 parts of polyorganosiloxane (BT-200 dimethyl silicone oil, purchased from Guangzhou Batai Chemical Co., Ltd.), 15 parts of 2,2-dimethylolpropionic acid, 13 parts of triethylamine parts, 80 parts of dimethylformamide, and 700 parts of deionized water.

Embodiment 2

[0039] A water-based polyurethane emulsion, comprising the following raw material components:

[0040] 100 parts of isophorone diisocyanate, 220 parts of polytetrahydrofuran diol, 14 parts of 1,4-butanediol, 5 parts of water-based epoxy resin emulsion (WS-500, purchased from Xinhua New Material Technology Co., Ltd.), 3 2 parts of methylolpropane, 6 parts of polyorganosiloxane (BT-200 dimethyl silicone oil, purchased from Guangzhou Batai Chemical Co., Ltd.), 12 parts of 2,2-dimethylolpropionic acid, 12 parts of triethylamine parts, 60 parts of dimethylformamide, and 500 parts of deionized water.

Embodiment 3

[0042] A water-based polyurethane emulsion, comprising the following raw material components:

[0043]100 parts of isophorone diisocyanate, 280 parts of polytetrahydrofuran diol, 18 parts of 1,4-butanediol, 8 parts of water-based epoxy resin emulsion (WS-500, purchased from Xinhua New Material Technology Co., Ltd.), 3 5 parts of methylol propane, 9 parts of polyorganosiloxane (BT-200 dimethyl silicone oil, purchased from Guangzhou Batai Chemical Co., Ltd.), 16 parts of 2,2-dimethylolpropionic acid, 15 parts of triethylamine parts, 90 parts of dimethylformamide, and 800 parts of deionized water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com