Flexible and transparent conductive thin film and preparation method thereof

A transparent conductive film, flexible technology, used in cable/conductor manufacturing, conductive layers on insulating carriers, circuits, etc. problems, to avoid the post-processing welding process, increase the adhesion of the substrate, and reduce the surface roughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

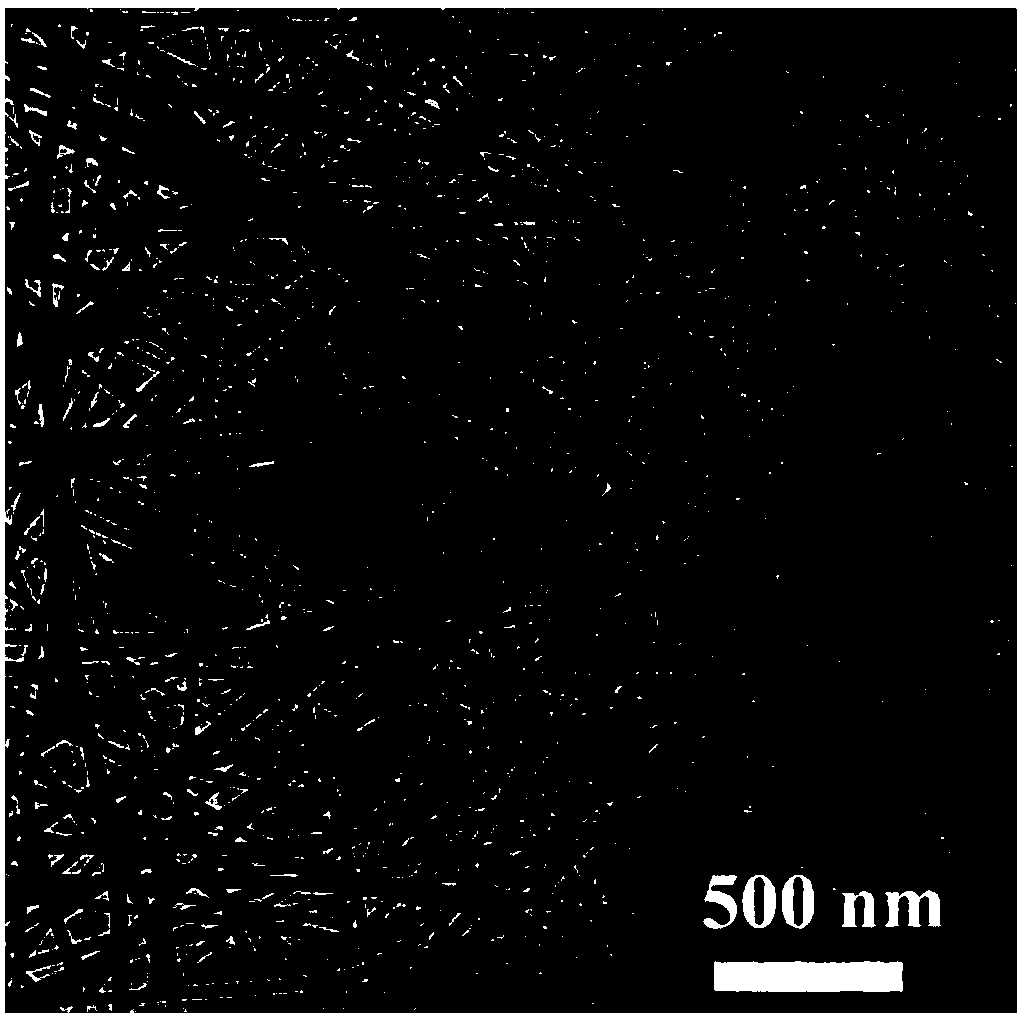

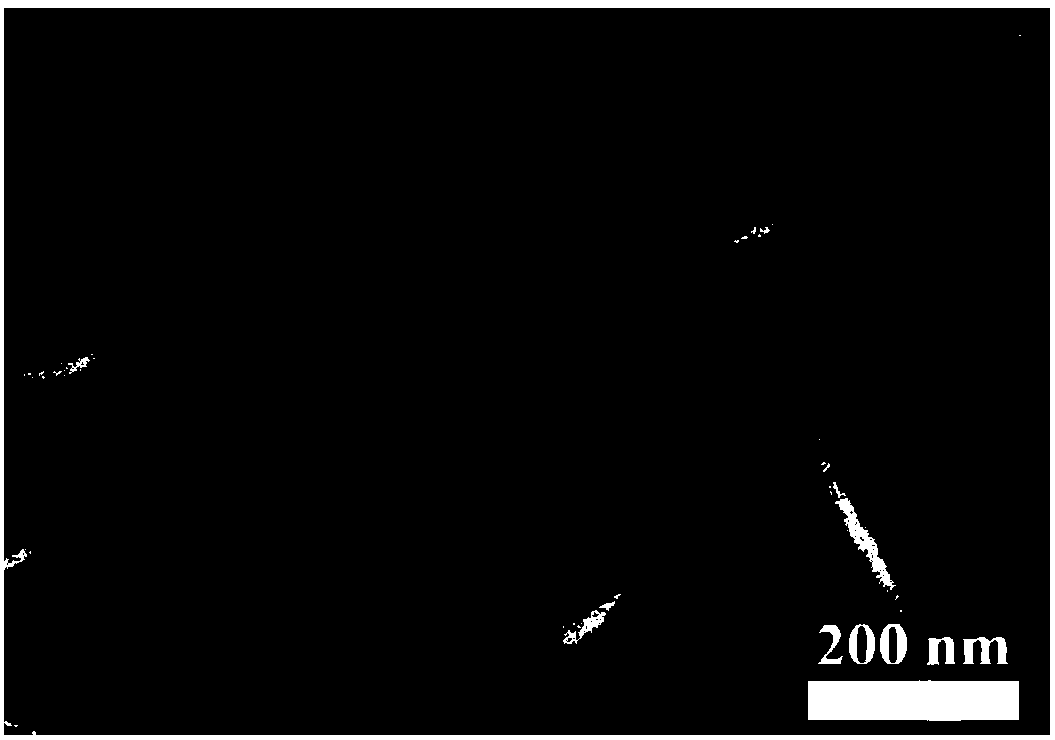

Image

Examples

Embodiment 1

[0034] A method for preparing a flexible transparent conductive film, comprising the following steps:

[0035] 1) Under stirring conditions, add 400mg graphene oxide to 400mL Tris buffer solution, adjust the pH value to 8.5, and ultrasonically disperse to obtain a graphene oxide dispersion; then add 200mg dopamine for oxidative polymerization, The reaction was carried out under the condition of stirring at 60°C for 24 hours, the color of the reaction solution gradually changed from brownish yellow to black, and a uniform reaction mixture was obtained. Oxidative polymerization occurs and the graphene oxide is reduced to graphene. At the same time, the amino group on the dopamine undergoes a covalent cross-linking reaction with the carboxyl group and epoxy group on the graphene oxide sheet, so that the reacted polydopamine is firmly adsorbed on the surface of the graphene sheet.

[0036] After the reaction was completed, the reaction mixture was filtered and washed several time...

Embodiment 2

[0065] A method for preparing a flexible transparent conductive film, comprising the following steps:

[0066] 1) Under stirring conditions, add 200mg graphene oxide to 400mL Tris buffer solution, adjust the pH value to 8.5, and ultrasonically disperse to obtain a graphene oxide dispersion; then add 400mg dopamine for oxidative polymerization, The reaction was carried out for 48 h under stirring at room temperature, the color of the reaction solution gradually changed from brownish yellow to black, and a uniform reaction mixture was obtained.

[0067] After the reaction was completed, the reaction mixture was filtered and washed several times to remove unreacted dopamine, and the filtered product was collected; the filtered product was dissolved in distilled water, centrifuged several times at 11,000 rpm until the supernatant was colorless, and the filtered product was removed. Graphene oxide that did not participate in the reaction, and the precipitate was collected, which wa...

Embodiment 3

[0082] A method for preparing a flexible transparent conductive film, comprising the following steps:

[0083]1) Under stirring conditions, add 100mg graphene oxide to 400mL Tris buffer solution, adjust the pH value to 8.5, and ultrasonically disperse to obtain a graphene oxide dispersion; then add 400mg dopamine for oxidative polymerization, The reaction was carried out under the condition of stirring at 60°C for 12 hours, the color of the reaction solution gradually changed from brownish yellow to black, and a uniform reaction mixture was obtained.

[0084] After the reaction was completed, the reaction mixture was filtered and washed several times to remove unreacted dopamine, and the filtered product was collected; the filtered product was dissolved in distilled water, centrifuged several times at 11,000 rpm until the supernatant was colorless, and the filtered product was removed. Graphene oxide that did not participate in the reaction, and the precipitate was collected, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com