Method for reducing TMA (trimethylaluminum) consumption of PECVD (plasma-enhanced chemical vapor deposition) machine

A machine and energy consumption technology, applied in the field of silicon solar cell manufacturing, to achieve the effect of reducing TMA consumption, reducing process pressure, and realizing TMA consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

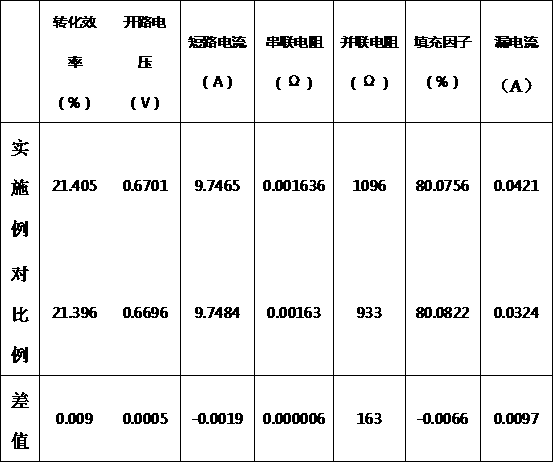

[0025] Embodiment: Adopt technology of the present invention

[0026] Use a P-type monocrystalline silicon wafer with a resistivity of 1.1-1.8Ω cm and a size of 156.75mm×156.75mm. After conventional texturing, diffusion, etching, and annealing, aluminum oxide film and aluminum oxide film are sequentially coated on a German Mayer PECVD machine. Silicon nitride film, where the process of the silicon nitride cavity remains unchanged.

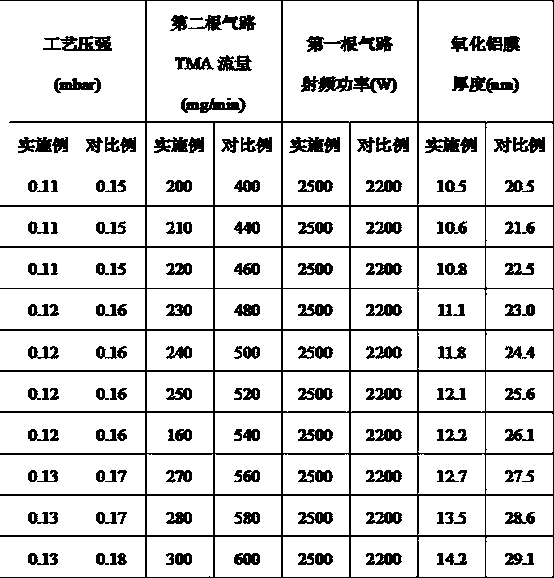

[0027] The process belt speed of the Maya PECVD alumina chamber is set at 185-200cm / min, the chamber temperature is set at 300-350°C, and the process pressure is set at 0.11-0.14mbar.

[0028] The Maya PECVD alumina chamber has two gas paths. Set the nitrous oxide flow rate of the first gas path to 600-700 sccm, the TMA flow rate to 0 mg / min, and the argon gas flow rate to 0 sccm. The laughing gas flow rate was set at 700-1000 sccm, the TMA flow rate was set at 200-300 mg / min, and the argon gas flow rate was set at 600-800 sccm.

[0029] At the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com