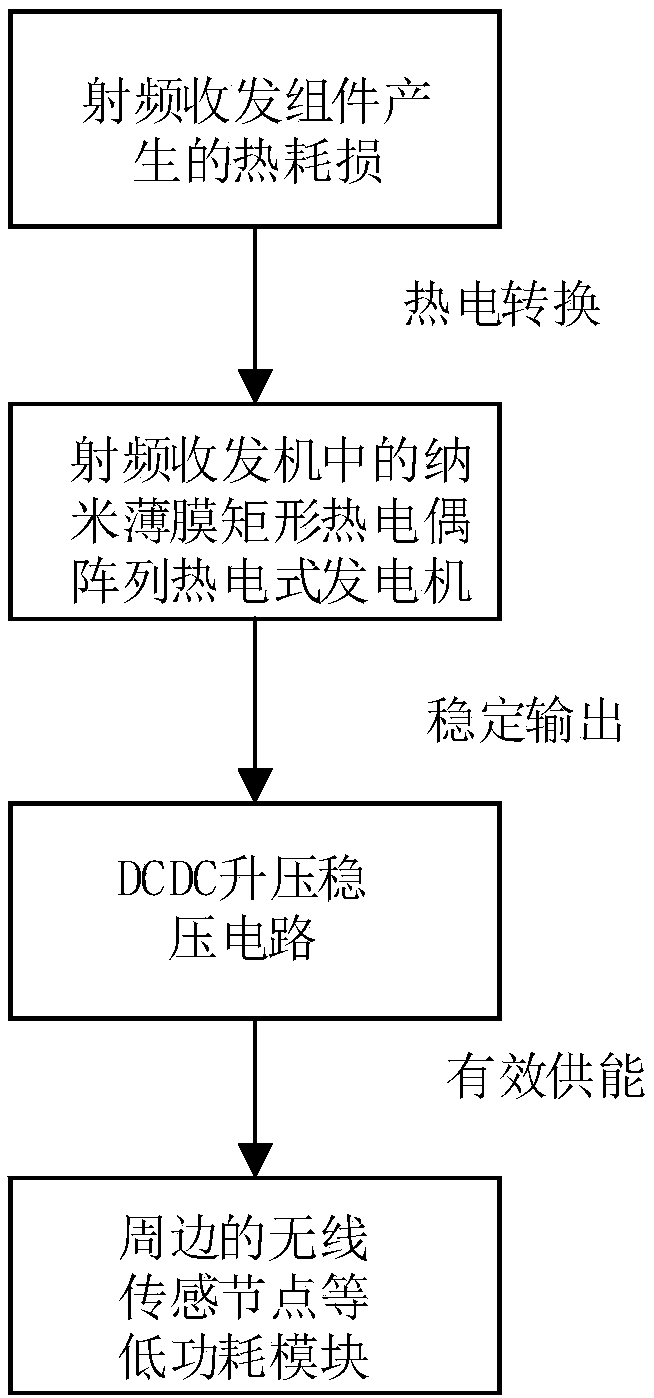

Nano-film rectangular thermocouple array thermoelectric micro-nano generator in radio frequency transceiver

A radio frequency transceiver and nano-thin film technology, which is applied in the field of nano-thin film rectangular thermocouple array thermoelectric micro-nano generators, can solve problems such as energy waste and reliability degradation, achieve long service life, high reliability, and improve thermoelectric power generation efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

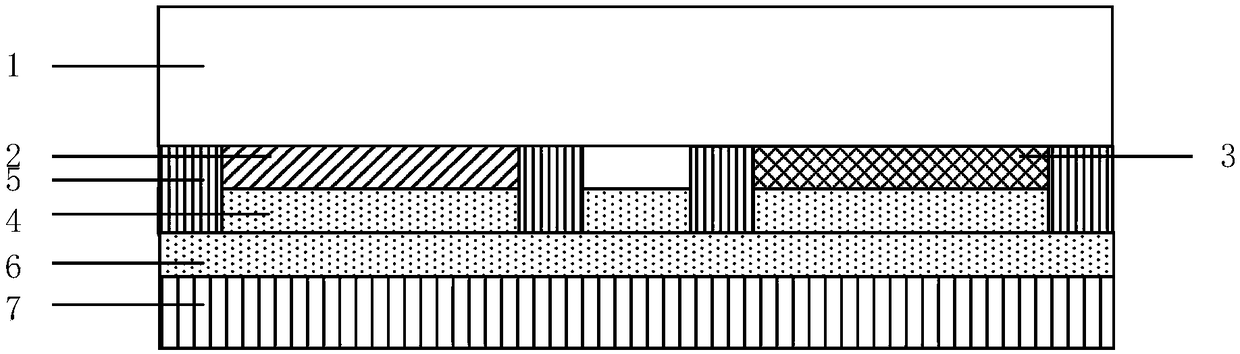

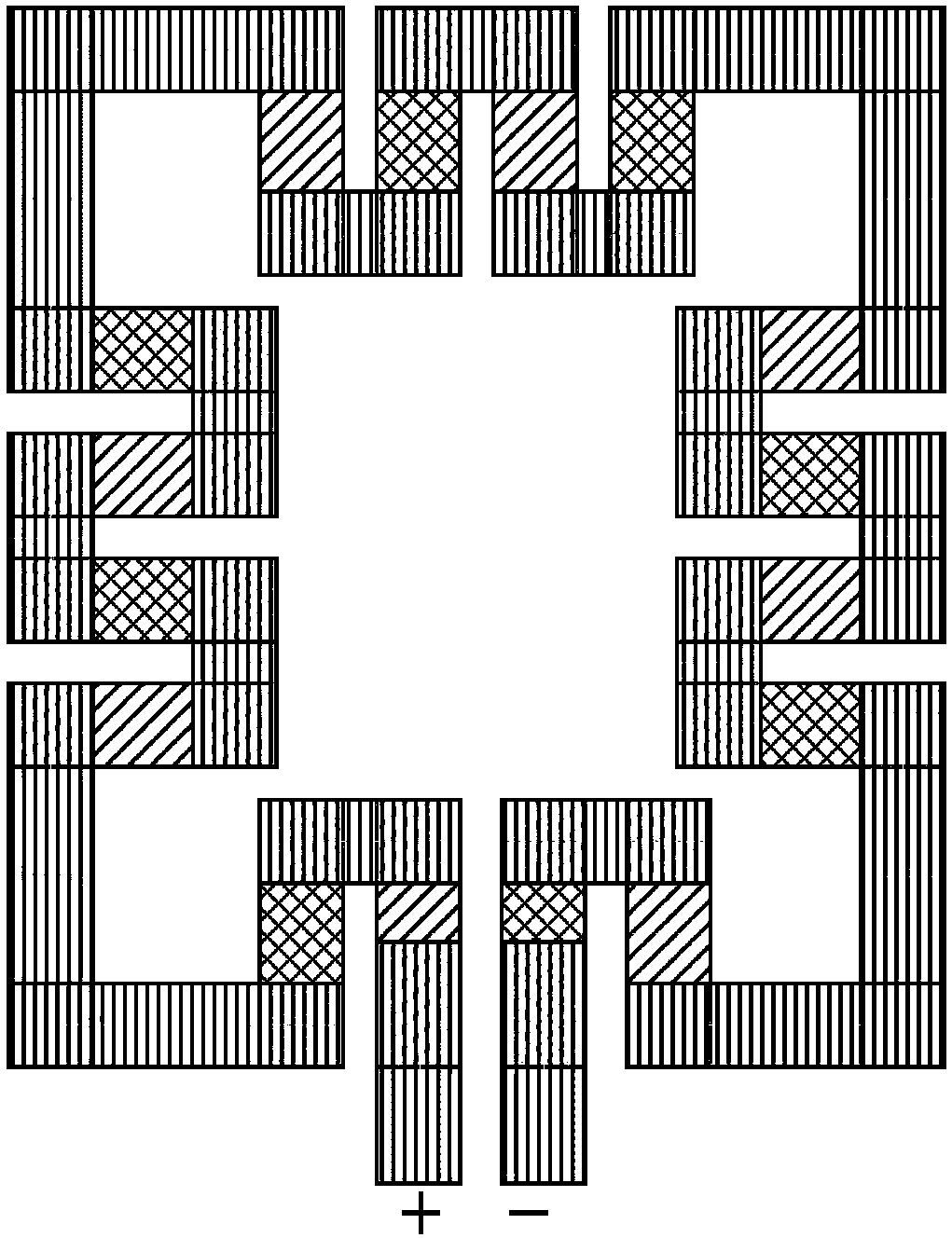

[0015] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0016] see Figure 1-3 , the present invention proposes a nano-thin film rectangular thermocouple array thermoelectric micro-nano generator in a radio frequency transceiver. The structure is composed of several thermopile units, each thermopile unit is composed of several thermocouples, and the thermocouples are composed of thermoelectric P-type arms and thermoelectric N-type arms. For the specific connection of thermopile units, see image 3 shown. N-type silicon is selected as the substrate 1, the phosphorus doping concentration is 1.0E15cm-3, and the resistivity is about 2Ωcm. Double-sided polishing is carried out before fabrication, and soaked in 0.55% HF acid solution to remove impurities such as metal particles, and then a periodic nano-silicon multilayer film is prepared on the substrate. Before the film deposition, the hydrogen gas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com