Nickel ferrite nanosheet as well as preparation method and application thereof

A technology of nickel ferrite and nanosheets, which is applied in the direction of nanotechnology, chemical instruments and methods, nickel compounds, etc., can solve the problems of limiting the application of catalyst supports and the single shape of nickel ferrite, and achieve broad industrial production prospects and practical applications value, shape integrity, and the effect of optimized process parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] In view of this, in a specific embodiment of the present invention, a kind of preparation method of nickel ferrite nanosheet is provided, comprising the following steps:

[0043] S1. Add iron salt and nickel salt to water and mix evenly;

[0044] S2. Add a precipitating agent to the solution obtained in step S1. and mix evenly;

[0045] S3. The solution obtained in step S2. is subjected to a hydrothermal reaction, and the product is purified to obtain a nickel ferrite precursor;

[0046] S4. Perform high-temperature heat treatment on the nickel ferrite precursor obtained in step S3. to obtain nickel ferrite nanosheets.

[0047] The possible principle of the method of the present invention is: the precipitation agent reacts at a certain temperature to generate OH - ,OH - It reacts with iron salt and nickel salt under certain conditions to form a flaky nickel ferrite precursor, and finally generates nickel ferrite nanosheets after high temperature heat treatment.

[0...

Embodiment 1

[0071] (1) Take by weighing 2.5mmol nickel chloride hexahydrate and 5mmol ferric chloride hexahydrate, join in 50ml deionized water, mix and stir for 30 minutes;

[0072] (2) Add 20mmol sodium acetate to the mixed solution, and sonicate for 30 minutes;

[0073] (3) Move the ultrasonically treated liquid into the reactor, and heat it at 180° C. for 12 hours to carry out the hydrothermal reaction;

[0074] (4) The product obtained after the hydrothermal reaction is completed is subjected to suction filtration, and the obtained substance is washed 3-4 times with deionized water;

[0075] (5) drying the obtained product at 60° C. for 10 h;

[0076] (6) Treat the dried product in a muffle furnace at 300° C. for 2 hours to obtain nickel ferrite powder.

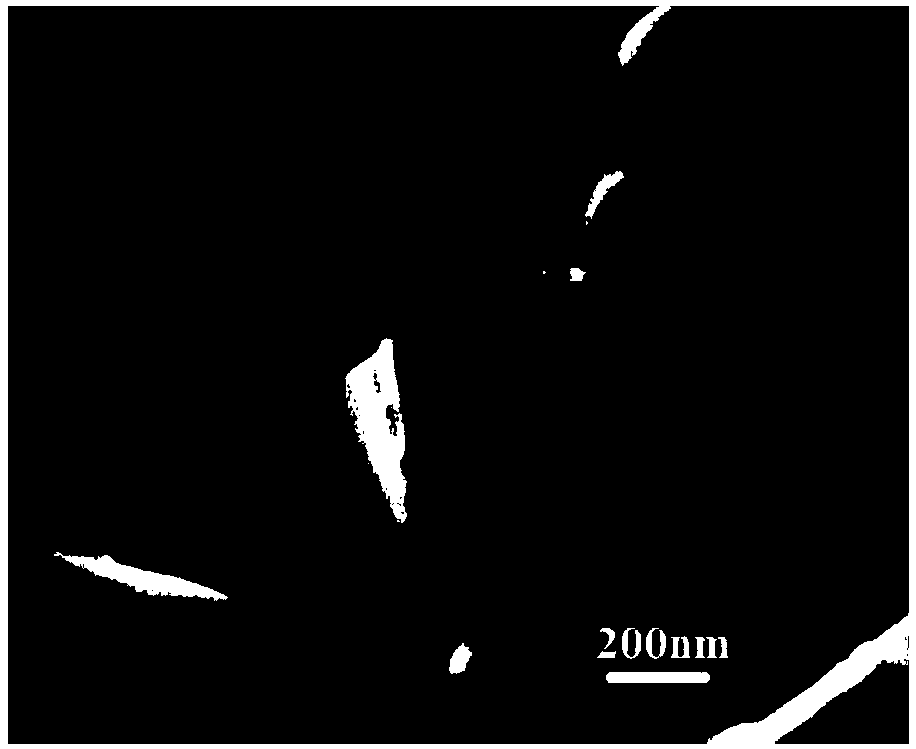

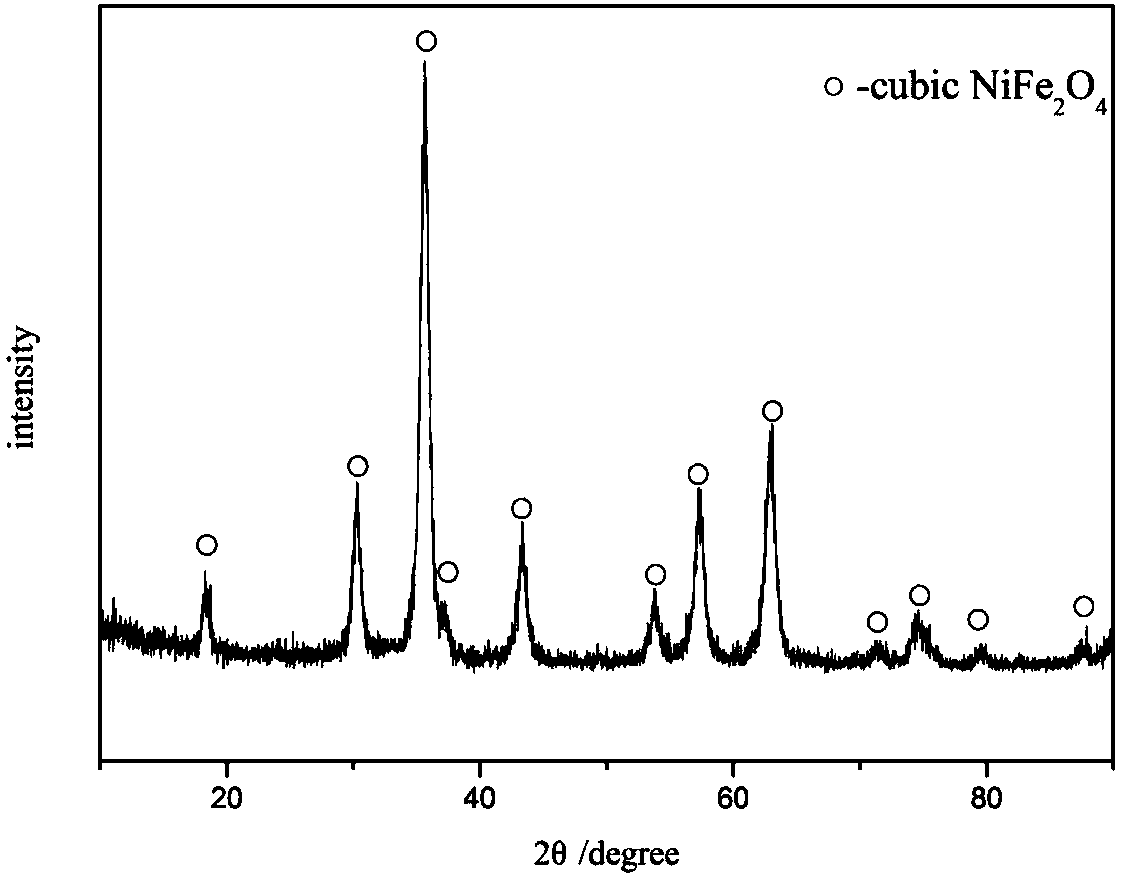

[0077] The scanning electron micrograph of the nickel ferrite nanosheet prepared by the present embodiment is as follows figure 1 As shown, the transmission electron microscope picture is shown as figure 2 As shown, the X-ray d...

Embodiment 2

[0079] (1) Weigh 2.5mmo nickel chloride hexahydrate and 5mmol ferric chloride hexahydrate, add to 100ml deionized water, mix and stir for 30 minutes;

[0080] (2) Add 30mmol urea to the mixed solution, and ultrasonically treat it for 30 minutes;

[0081] (3) Move the ultrasonically treated liquid into the reactor, and heat it at 200° C. for 10 hours to carry out the hydrothermal reaction;

[0082] (4) The product obtained after the hydrothermal reaction is completed is subjected to suction filtration, and the obtained substance is washed 3-4 times with deionized water;

[0083] (5) drying the obtained product at 60° C. for 10 h;

[0084] (6) Treat the dried product in a muffle furnace at 300° C. for 2 hours to obtain nickel ferrite powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com