Novel nitrating process of 3-nitro-4-chlorobenzotrifluoride

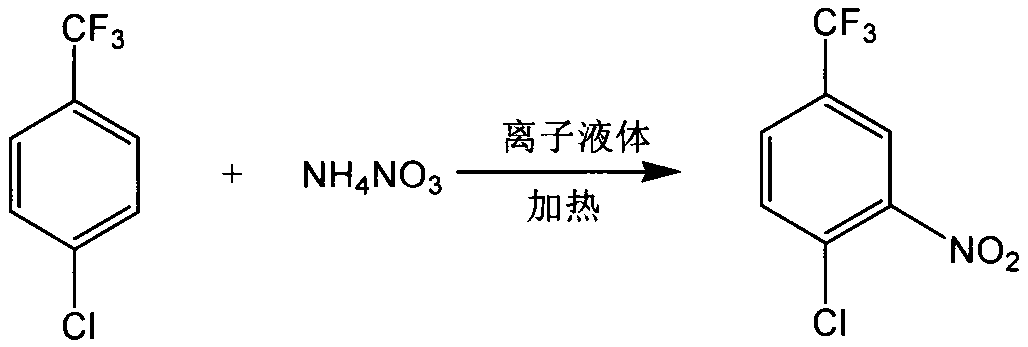

The technology of chlorotrifluorotoluene and p-chlorotrifluorotoluene is applied in the field of novel nitration technology of 3-nitro-4-chlorotrifluorotoluene, and can solve the problems of unfavorable large-scale popularization and application, pollution, high equipment corrosion, etc., Achieving good industrial application prospects, wide source of raw materials, and less corrosion of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

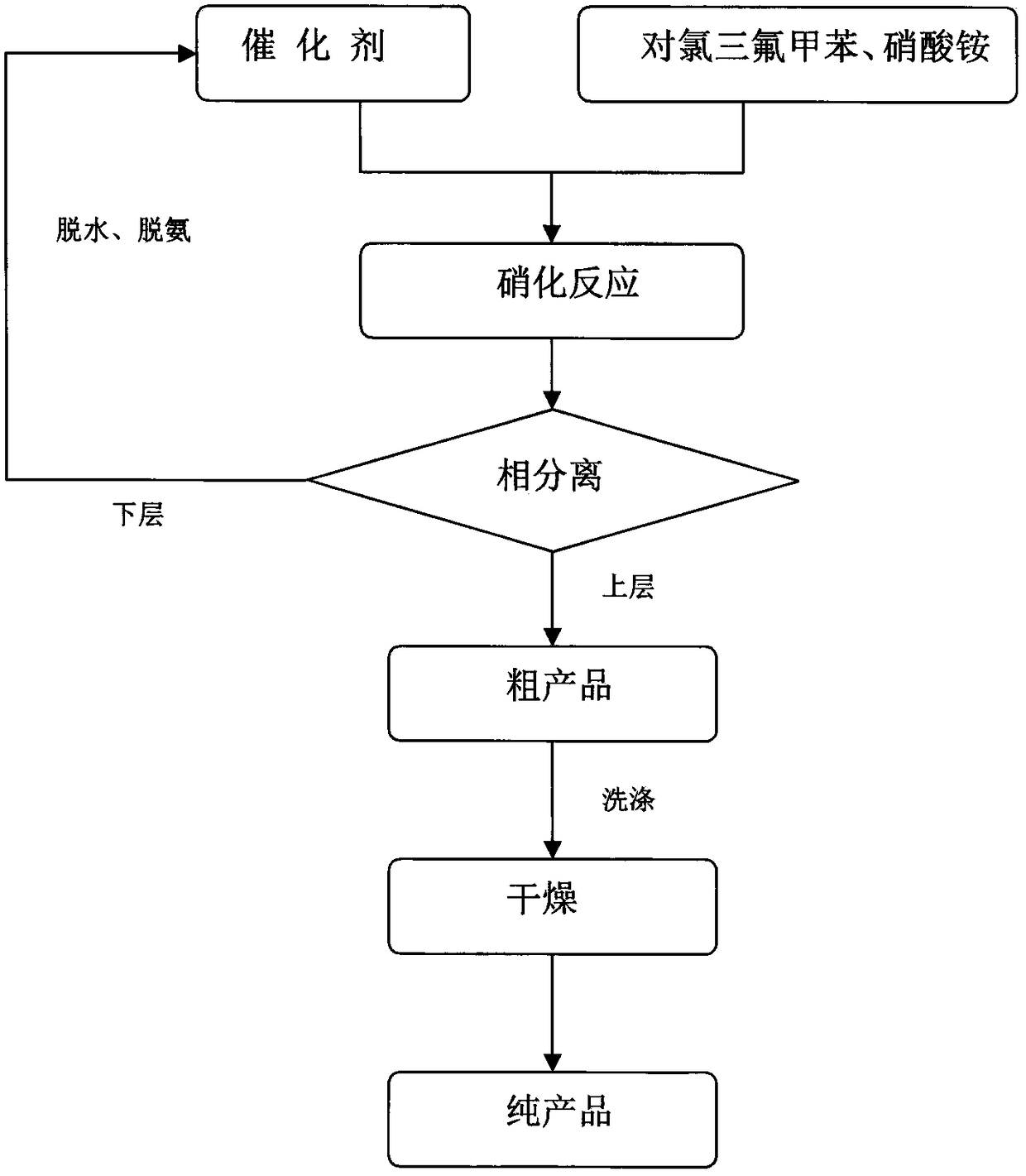

Method used

Image

Examples

Embodiment 1

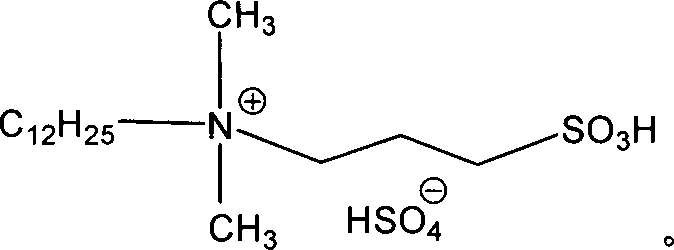

[0019] In a 25mL round-bottom flask, add 10mmol (1.81g) p-chlorobenzotrifluoride, 10mmol (0.8g) ammonium nitrate, 8mmol (3.47g) ionic liquid, mix and stir for 4 hours at 50℃, cool and stand still The phases are separated, the upper crude product is washed, neutralized, and vacuum dried to obtain the pure product 3-nitro-4-chlorobenzotrifluoride with a yield of 83% and a content of more than 99%.

Embodiment 2

[0021] In a 25mL round-bottom flask, add 10mmol (1.81g) p-chlorobenzotrifluoride, 30mmol (1.8g) ammonium nitrate, 4mmol (1.72g) ionic liquid, mix and stir at 60℃ for 10 hours, cool and stand still The phases are separated, the upper crude product is washed, neutralized, and vacuum dried to obtain the pure product 3-nitro-4-chlorobenzotrifluoride with a yield of 82% and a content of more than 99%.

Embodiment 3

[0023] In a 25mL round-bottom flask, add 10mmol (1.81g) p-chlorobenzotrifluoride, 20mmol (1.2g) ammonium nitrate, 5mmol (2.2g) ionic liquid, mix and stir at 70℃ for 8 hours, cool and stand still The phases are separated, the upper crude product is washed, neutralized, and vacuum dried to obtain the pure product 3-nitro-4-chlorobenzotrifluoride with a yield of 83% and a content of more than 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com