Synthesis method of chloromethyl thiazole

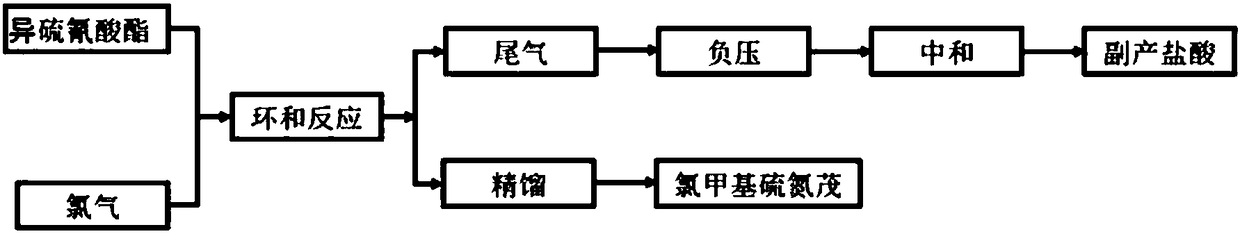

A technology for chloromethylthionitrone and chloromethylthionitrogen, which is applied in the synthesis field of chloromethylthionitrone, can solve problems such as difficult operation, large pollution, complicated procedures, etc., and achieves a high degree of automation and process safety. Controllable and reasonable process design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

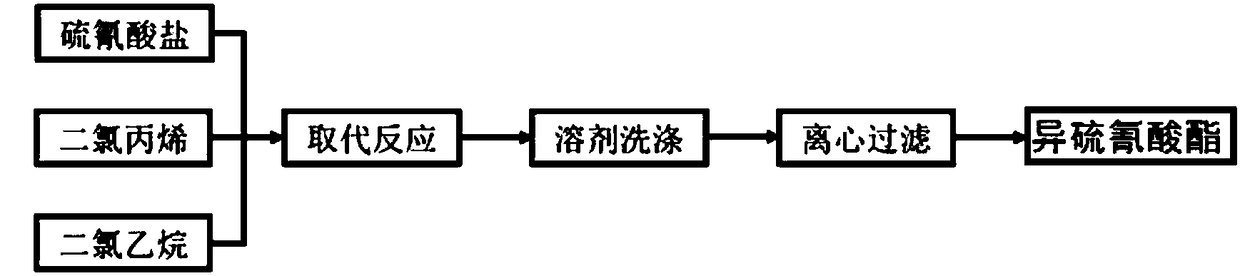

[0045] Example 1-4: Synthesis of 1-isothiocyanato-2-chloro-2-propene:

Embodiment 1

[0046]Example 1: 150g of 2,3-dichloropropene, 108g of sodium thiocyanate, and 150g of dichloromethane were added to a 500ml three-necked flask, and the spherical condenser was passed through a 0-5 degree ice salt water, heated in a water bath, slightly refluxed, and refluxed for 3 reactions After 2 hours, the content of 2,3-dichloropropene was detected to be lower than 0.2%, and the material was cooled to below 10 degrees with ice brine, filtered, and the filter cake was washed with 150 g of dichloromethane to combine the mother liquor for the next step of synthesis. The content of the product 1-isothiocyanato-2-chloro-2-propene was >99.5%, and the internal standard of the product was used to obtain 180 g of the product 1-isothiocyanato-2-chloro-2-propene, with a yield of 99.5%.

Embodiment 2

[0047] Example 2: In a 500ml three-necked flask, add 150g of water and 108g of sodium thiocyanate, stir for 10 minutes to dissolve, add 150g of 2,3-dichloropropene, slowly heat up to 50-60 degrees to react, and the spherical condenser tube is fed with frozen brine, React for 2-3 hours, check the end point, the content of 2,3-dichloropropene is less than 0.2%, then cool the material to below 10 degrees, pour it into a separatory funnel to separate layers, and add sodium to treat the upper layer of saline wastewater. 178 g of 1-isothiocyanato-2-chloro-2-propene in the lower organic phase was collected, with a content of 99.5% and a yield of 98.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com