Wood paint base material

A lacquer-based and wood-based technology, which is applied in the field of wood-based lacquer base materials, can solve the problem of low binding force of carboxylated styrene-butadiene latex, and achieve the effects of good mechanical and chemical stability, good performance, and uniform molecular weight distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-2 and comparative example 1-4

[0037] Effect of mass ratio of vinyl toluene, butadiene and styrene on properties of wood paint base

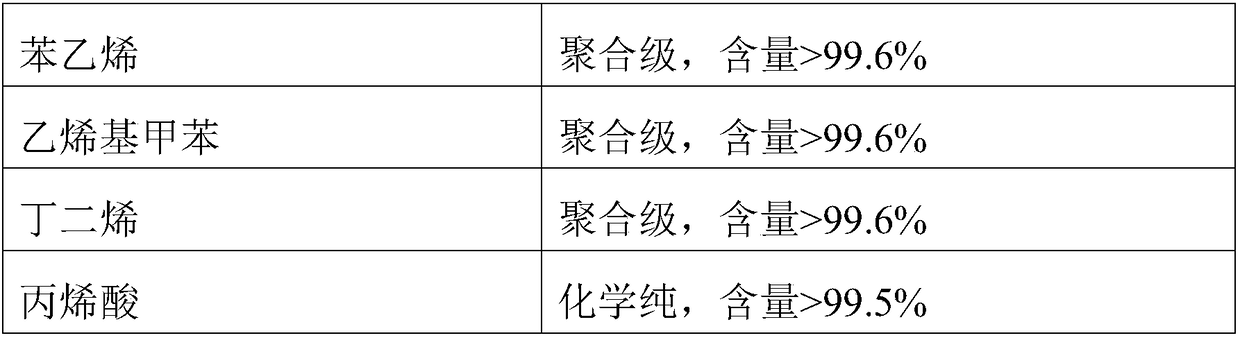

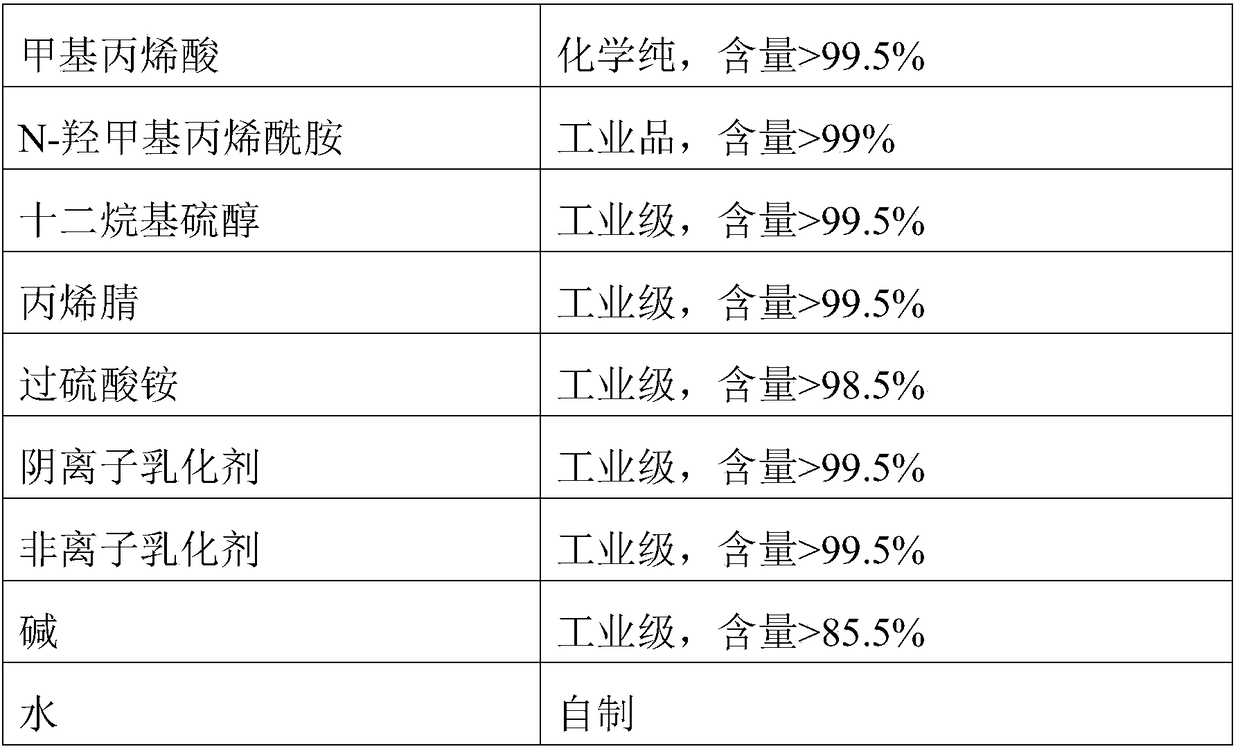

[0038] Embodiment 1-2 and comparative example 1-4 provide wood lacquer base material, and the parts by weight of preparation raw material are composed as follows:

[0039] The mass parts of butadiene, styrene and vinyl toluene are shown in Table 3, 2 parts of acrylic acid, 1 part of N-methylolacrylamide, 1.4 parts of anionic emulsifier (sodium lauryl sulfate), nonionic emulsifier ( S-120) 0.6 parts, ammonium persulfate 2 parts, dodecyl mercaptan 0.8 parts, water 100 parts, alkali 0.8 parts, seed emulsion 2 parts;

[0040] Prepared by the following method:

[0041] S1: Prepare a mixed aqueous solution of N-methylolacrylamide, anionic emulsifier (sodium lauryl sulfate) and nonionic emulsifier (S-120), alkaline aqueous solution and ammonium persulfate aqueous solution with water;

[0042] S2: Add the remaining water and seed emulsion to the polymerization kettle, vacuumize the...

Embodiment 3-5 and comparative example 5-10

[0059] Effect of Polymerization Reaction Time on Properties of Wood Lacquer Binder

[0060] Embodiment 3-5 and comparative example 5-10 provide wood lacquer base material, and the parts by weight of preparation raw material are composed as follows:

[0061] 40 parts of butadiene, 30 parts of styrene, 30 parts of vinyl toluene, 3 parts of methacrylic acid, 1.5 parts of acrylamide, 1.4 parts of anionic emulsifier (sodium dodecylbenzenesulfonate), nonionic emulsifier (S -120) 0.6 part, 2 parts of sodium persulfate, 0.5 part of dodecyl mercaptan, 90 parts of water, 0.5 part of alkali, 2 parts of seed emulsion;

[0062] Prepared by the following method:

[0063] S1: Prepare a mixed aqueous solution of acrylamide, anionic emulsifier (sodium dodecylbenzenesulfonate) and nonionic emulsifier (S-120), alkaline aqueous solution and sodium persulfate aqueous solution with water;

[0064] S2: Add the remaining water and seed emulsion into the polymerization kettle, vacuumize the inside o...

Embodiment 6-7 and comparative example 11

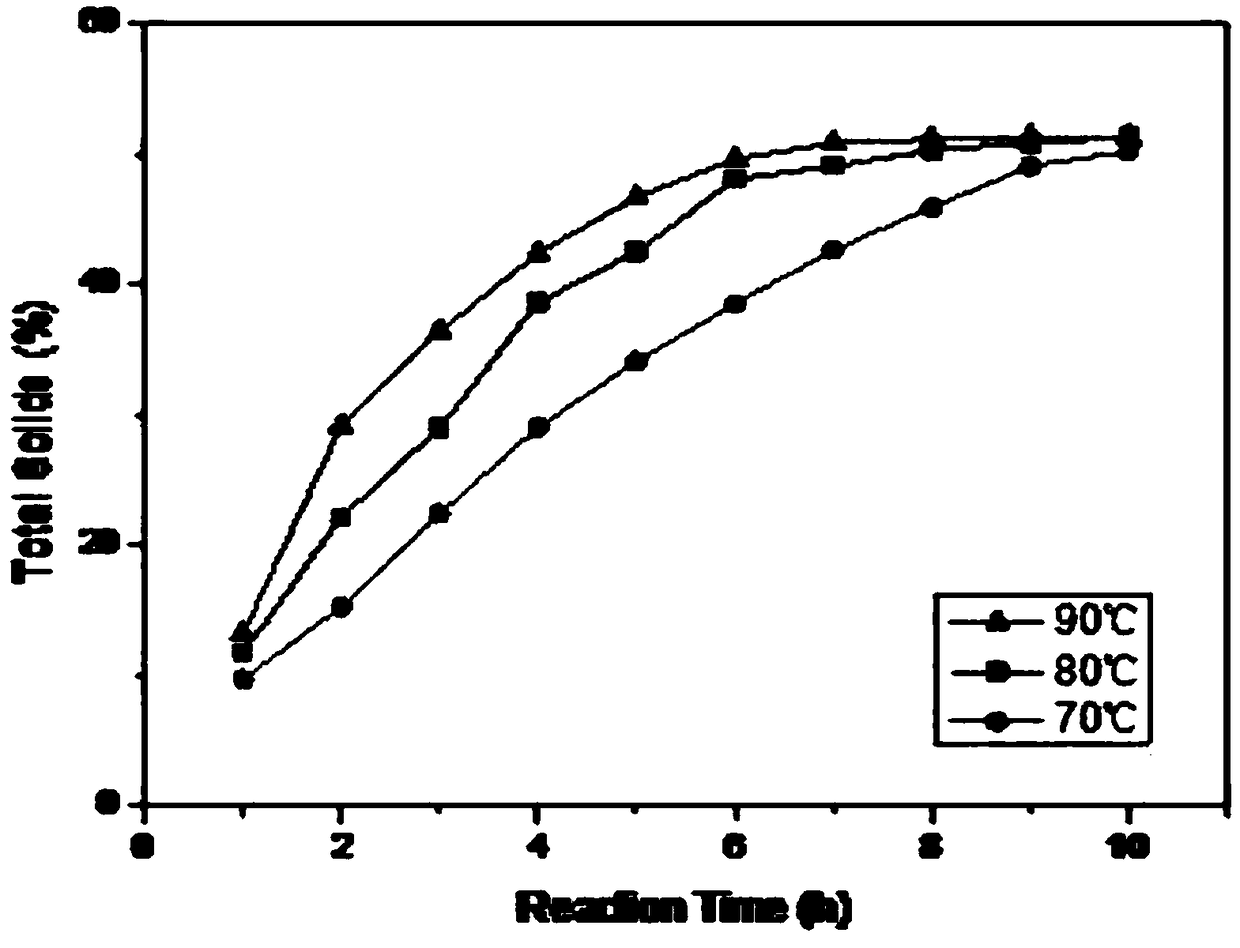

[0079] Effect of Polymerization Temperature on Polymerization Speed of Wood Lacquer Binder

[0080] Embodiment 6-7 and comparative example 11 provide wood lacquer base material, and the weight part composition of raw material is as follows:

[0081] 40 parts of butadiene, 30 parts of styrene, 30 parts of vinyltoluene, 1 part of itaconic acid, 0.5 parts of N-methylolacrylamide, 1.4 parts of anionic emulsifier (sodium dodecylsulfonate), nonionic 0.6 parts of emulsifier (S-120), 2 parts of sodium persulfate, 1 part of dodecyl mercaptan, 110 parts of water, 1 part of alkali, 2 parts of seed emulsion;

[0082] Prepared by the following method:

[0083] S1: Prepare a mixed aqueous solution of acrylamide, anionic emulsifier (sodium dodecylsulfonate) and nonionic emulsifier (S-120), alkaline aqueous solution and sodium persulfate aqueous solution with water;

[0084] S2: Add the remaining water and seed emulsion into the polymerization tank, vacuumize the inside of the polymerizat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com