Efficient anti-ultraviolet wear-resistant super-hydrophobic cotton fabric and preparation method thereof

An anti-ultraviolet and high-efficiency technology, applied in the direction of wear-resistant fibers, plant fibers, light-resistant fibers, etc., can solve the problems of complex preparation process of super-hydrophobic cotton fabrics and unfavorable large-scale application, and achieve good super-hydrophobic performance, which is beneficial to Effects of large-scale promotion and improvement of UV protection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The first aspect of the present invention provides a kind of preparation method of highly efficient anti-ultraviolet wear-resisting superhydrophobic cotton fabric, comprises the following steps:

[0020] S1. Dispersing micron-sized particles, nano-sized particles and silane coupling agent into the first organic solvent to form solution A;

[0021] S2. Dispersing polydimethylsiloxane, curing agent and isocyanate crosslinking agent into a second organic solvent to form solution B;

[0022] S3. After immersing the cotton fabric in solution A, take it out, and then immerse it in solution B after drying, take it out and dry it, and obtain a highly efficient UV-resistant and wear-resistant super-hydrophobic cotton fabric.

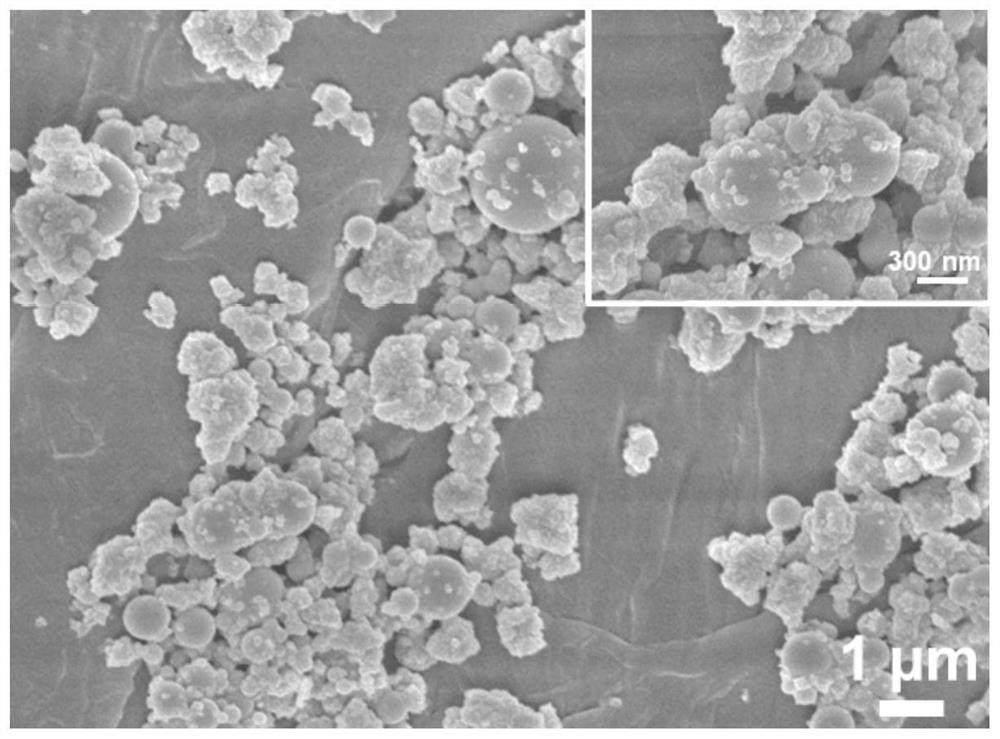

[0023] In step S1 of the present invention, dispersing the micron-sized particles, nano-sized particles and silane coupling agent into the first organic solvent to form solution A includes: adding the micron-sized particles and nano-sized particles into th...

Embodiment 1

[0030] (1) The pure cotton fabric is rinsed three times with water and ethanol respectively, to remove the impurities on the surface;

[0031] (2) Add 0.8g of mixed particles of micron-sized silicon dioxide (average particle size 1 micron) and nano-sized titanium dioxide (particle size 1-10 nm) with a mass ratio of 1:0 to 50ml of ethanol, and then add them after ultrasonic dispersion 50 μL N-[3-(trimethoxysilyl)propyl]ethylenediamine and magnetically stirred for 1 hour to form solution A;

[0032] (3) Dissolve 1g of polydimethylsiloxane and 0.1g of curing agent (Sylgard184) in 74ml of n-hexane, after ultrasonic dispersion, add 80μL of hexamethylene diisocyanate trimer and stir for 30min to form solution B;

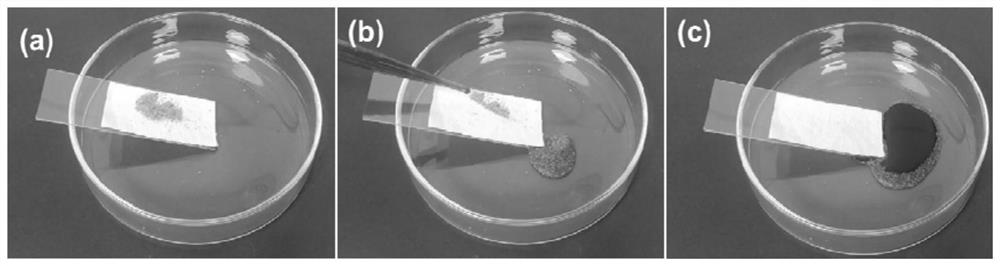

[0033] (4) Immerse the cotton fabric in solution A for 50 minutes, take it out, and dry it at room temperature, then immerse it in solution B for 1 minute, take it out, put it in a 50°C oven and dry it for 2 hours to obtain a superhydrophobic cotton fabric.

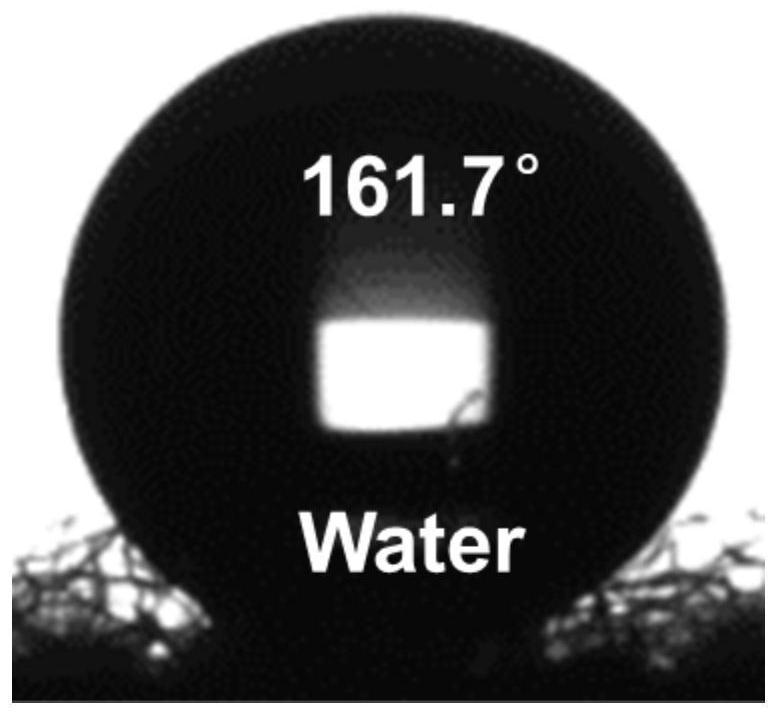

[0034] It is...

Embodiment 2

[0036] (1) The pure cotton fabric is rinsed three times with water and ethanol respectively, to remove the impurities on the surface;

[0037] (2) Add 0.8 g of mixed particles of micron-sized silica (average particle size 1 micron) and nano-sized titanium dioxide (particle size 1-10 nm) with a mass ratio of 3:1 into 50 ml of ethanol, and then add them after ultrasonic dispersion 50 μL N-[3-(trimethoxysilyl)propyl]ethylenediamine and magnetically stirred for 1 hour to form solution A;

[0038](3) Dissolve 1g of polydimethylsiloxane and 0.1g of curing agent (Sylgard184) in 74ml of n-hexane, after ultrasonic dispersion, add 80μL of hexamethylene diisocyanate trimer and stir for 30min to form solution B;

[0039] (4) Immerse the cotton fabric in solution A for 50 minutes, take it out, and dry it at room temperature, then immerse it in solution B for 1 minute, take it out, put it in a 50°C oven and dry it for 2 hours to obtain a superhydrophobic cotton fabric.

[0040] It is measu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com