Polycarbosilane and polysiloxane resin-based ablation-resistant composite material and preparation method thereof

A technology of polysiloxane resin and polycarbosilane, which is applied in the field of organic silicon polymer composite materials, can solve the problems of high viscosity of rubber materials, insufficient storage stability of rubber materials, and easy hydrolysis of polysilazane, etc. Low viscosity, improved ablation performance, and improved adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

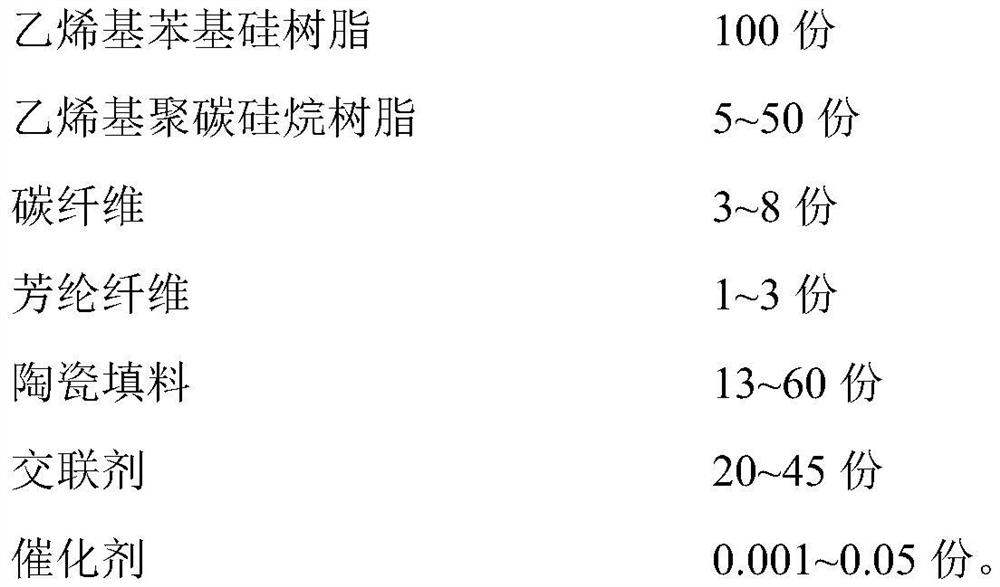

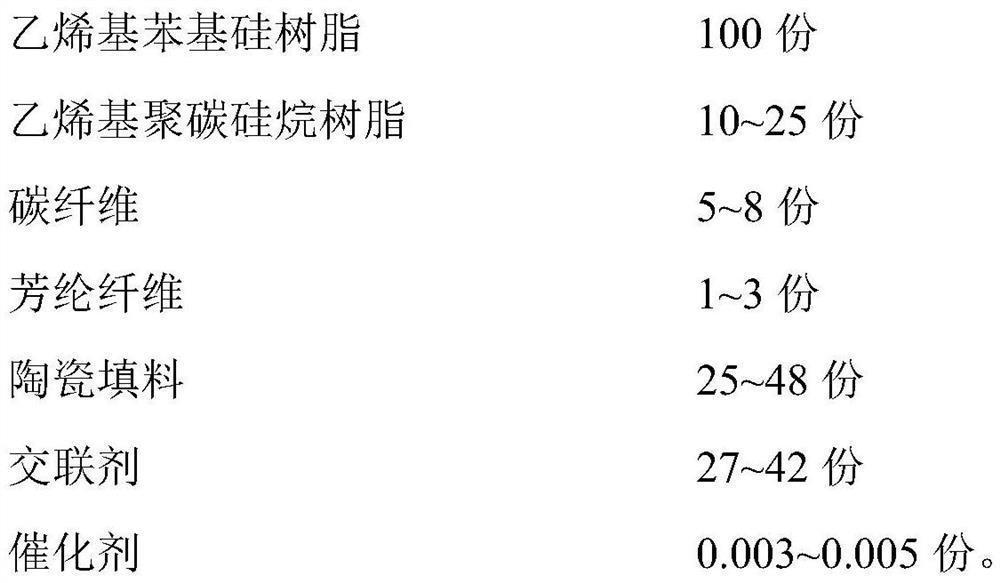

[0022]

[0023]

[0024] Among them, vinyl phenyl silicone resin, Vi content 5.6wt.%, R / Si (the molar ratio of the two, the same below) = 1.48, Ph / R (the molar ratio of the two, the same below) = 48.62%; Carbosilane resin, Vi content 9.5wt.%, viscosity (25 ° C) 1500mpa s; crosslinking agent is phenyl hydrogen polysiloxane, hydrogen content 1.05wt.%, phenyl content 32wt.%; catalyst is A tetramethyldivinyldisiloxane complex with a platinum content of 2wt.%; ceramic fillers are made by mixing zirconium boride, zirconium oxide, aluminum oxide, and titanium dioxide in a mass ratio of 22:5:5:1.

[0025] The preparation method is as follows:

[0026] Using a grinding machine, add vinyl phenyl silicone resin, vinyl polycarbosilane resin, carbon fiber, aramid fiber, ceramic filler, and crosslinking agent in sequence, and mix the materials to obtain a rubber compound with uniform dispersion and stable performance. The viscosity ( 25°C) 9.75 Pa·s. Add catalyst, mix evenly, use va...

Embodiment 2

[0028]

[0029] Among them, vinyl phenyl silicone resin, Vi content 5.6wt.%, R / Si=1.48, Ph / R=48.62%; Vinyl polycarbosilane resin, Vi content 4.7wt.%, viscosity (25 ℃) 2800mpa. s; the crosslinking agent is phenyl hydrogen-containing polysiloxane, the hydrogen content is 0.75wt.%, and the phenyl content is 24wt.%; the catalyst is tetramethyldivinyldisiloxane complex with platinum content of 2wt.%. compound; the ceramic filler is made of zirconium boride, zirconia, alumina, and titanium dioxide in a mass ratio of 14.7:5:5:1.

[0030] The preparation method is as follows:

[0031] Using a grinding machine, add vinyl phenyl silicone resin, vinyl polycarbosilane resin, carbon fiber, aramid fiber, ceramic filler, and crosslinking agent in sequence, and mix the materials to obtain a rubber compound with uniform dispersion and stable performance. The viscosity ( 25°C) 8.6 Pa·s. Add catalyst, mix evenly, use vacuum degassing machine to remove air bubbles, and cure. After curing (cu...

Embodiment 3

[0033]

[0034]Among them, vinyl phenyl silicone resin, Vi content 3.5wt.%, R / Si=1.42, Ph / R=28.3%; Vinyl polycarbosilane resin, Vi content 1.3wt.%, viscosity (25 ℃) 2500mpa. s; the crosslinking agent is phenyl hydrogen-containing polysiloxane, the hydrogen content is 0.35wt.%, and the phenyl content is 22.5wt.%. The catalyst is tetramethyldivinyl disiloxane with a platinum content of 2wt.%. Complexes; ceramic fillers are made by mixing zirconium boride, boron nitride, chromium oxide, and aluminum oxide in a mass ratio of 10.7:2:1:5.

[0035] The preparation method is as follows:

[0036] Using a grinding machine, add vinyl phenyl silicone resin, vinyl polycarbosilane resin, carbon fiber, aramid fiber, ceramic filler, and crosslinking agent in sequence, and mix the materials to obtain a rubber compound with uniform dispersion and stable performance, with a viscosity of 9.5 (25°C) Pa·s. Add catalyst, mix evenly, use vacuum degassing machine to remove air bubbles, and cure. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com