Ecological and environment-friendly coating for straw and preparation method thereof

An environmentally friendly coating and ecological technology, applied in the field of coatings, can solve problems such as single function and insufficient environmental protection, and achieve the effects of simple preparation process, avoiding mildew and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

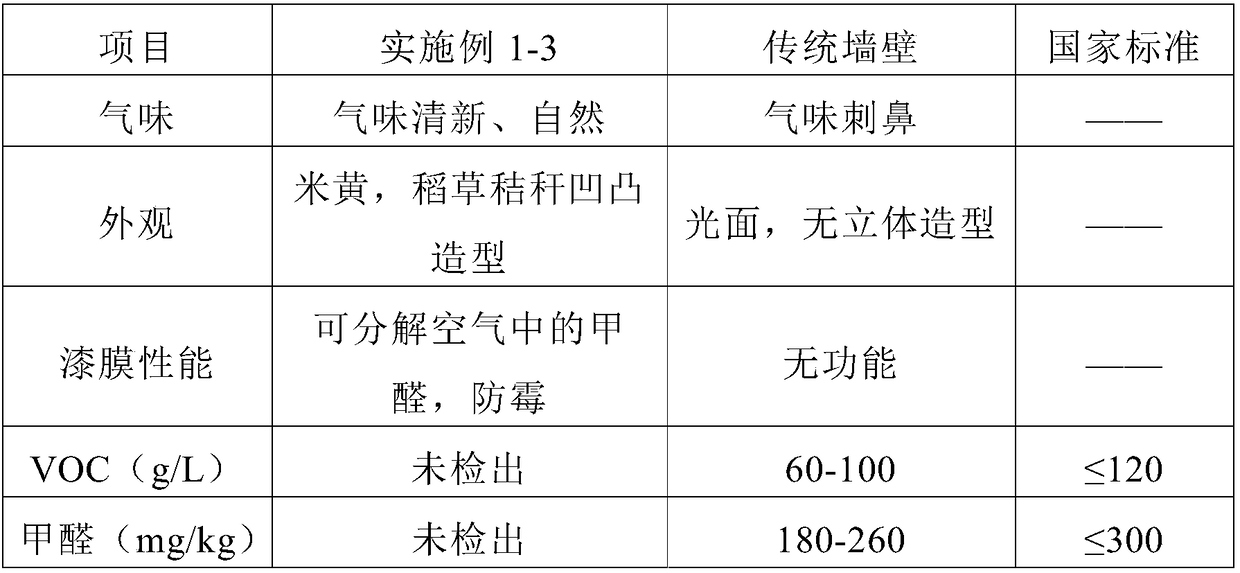

Examples

Embodiment 1

[0026] A kind of straw eco-friendly coating, comprising the following components: 20kg of emulsion, 5kg of natural colored sand, 2kg of rubber powder, 0.2kg of cellulose ether, 0.6kg of diatomaceous earth, 0.1kg of anti-mildew and antibacterial agent, 2kg of film-forming aid, dispersion 2kg of antifoaming agent, 2kg of thickener, 10kg of deionized water, 4kg of wood pulp, 0.5kg of rice straw with a length of 0.1-0.5cm, 0.7kg of rice straw with a length of 0.5-1cm, and a length of 1-1.5 cm straw 0.8kg.

[0027] Among them, the emulsion is styrene-acrylic emulsion, the natural colored sand is selected from yellow sand with a particle size of 20-40 mesh, the rubber powder is styrene-acrylate, the cellulose ether is hydroxyethyl cellulose, and the anti-mold and antibacterial agent is benzimidazole amino Methyl formate, propylene glycol butyl ether as a film-forming aid, polycarboxylate sodium salt anionic dispersant as a dispersant, polyurethane thickener as a thickener, and metal...

Embodiment 2

[0033] A kind of straw eco-friendly coating, comprising the following components: 25kg of emulsion, 10kg of natural colored sand, 3kg of rubber powder, 0.5kg of cellulose ether, 1.5kg of diatomaceous earth, 0.6kg of anti-mildew and antibacterial agent, 4kg of film-forming aid, dispersion 4kg of antifoaming agent, 3kg of thickener, 15kg of deionized water, 5kg of wood pulp, 0.7kg of rice straw with a length of 0.1-0.5cm, 0.9kg of rice straw with a length of 0.5-1cm, and a length of 1-1.5 cm straw 1kg.

[0034] Among them, the emulsion is pure acrylic elastic emulsion, the natural colored sand is selected from yellow sand with a particle size of 20-40 mesh, the rubber powder is VAE rubber powder, the cellulose ether is methyl cellulose, and the anti-mold and antibacterial agent is benzimidazole carbamate ester, the film-forming aid is propylene glycol methyl ether acetate, the dispersant is polycarboxylate sodium salt anionic dispersant, the thickener is polyurethane thickener, ...

Embodiment 3

[0037] A kind of straw eco-friendly paint, comprising the following components: 22kg of emulsion, 7kg of natural colored sand, 2.5kg of rubber powder, 0.3kg of cellulose ether, 1.3kg of diatomaceous earth, 0.5kg of anti-mildew and antibacterial agent, 3kg of film-forming aid, Dispersant 3kg, defoamer 4.5kg, thickener 2.5kg, deionized water 13kg, wood pulp 4.4kg, rice straw 0.1-0.5cm in length 0.6kg, rice straw 0.5-1cm in length 0.8kg, length 0.9kg of rice straw 1-1.5cm. Wherein, the emulsion is a silicone acrylic emulsion, and the rest are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com