Hydrophobic and oleophobic self-cleaning coating, preparation method and application of hydrophobic and oleophobic self-cleaning coating and solar equipment

A hydrophobic, oleophobic, and self-cleaning technology, applied in antifouling/underwater coatings, coatings, paints containing biocides, etc., can solve the problems of low efficiency, low dust removal efficiency, and high cost, and achieve good controllability of conditions , high energy storage efficiency, high binding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The preparation method of the hydrophobic and oleophobic self-cleaning coating of the embodiment of the present invention may include the following steps, for example: mixing fluorine-containing olefin monomers, nanoparticles and inducers; the inducers include (NH 4 ) 2 S 2 o 8 .

[0021] Fluorocarbon polymers not only have excellent durability and chemical stability and excellent surface properties, but also exhibit excellent hydrophobic and oleophobic properties. The fluorine-containing olefin monomer is used as one of the raw materials in the embodiment of the present invention. The reason is that compared with hydrogen atoms, fluorine atoms are easier to shield the C-F structure, which can effectively protect the carbon atoms and carbon chains in the matrix material, and the carbon The longer the chain, the more fluorine atoms there are, and the more hydrophobic the material.

[0022] As an option, the types of fluorine-containing olefin monomers in the embodime...

Embodiment 1

[0035] Tridecafluorooctyl methacrylate and dodecafluoroheptyl acrylate were uniformly mixed in a polymerization vessel at a volume ratio of 1:1.5 at a speed of 300 r / min.

[0036] Add nano-core-shell structure SiO to the well-mixed olefin monomer 2 Granules, mix evenly at the same speed.

[0037] At a speed of 450r / min, add (NH 4 ) 2 S 2 o 8 Induces polymerization of olefin monomers. After reacting for 30 minutes, cool naturally to obtain a hydrophobic and oleophobic self-cleaning coating.

Embodiment 2

[0039] Tridecafluorooctyl methacrylate and dodecafluoroheptyl acrylate were uniformly mixed in a polymerization vessel at a volume ratio of 1:1 at a rotational speed of 250 r / min.

[0040] Add nano-core-shell structure SiO to the well-mixed olefin monomer 2 Granules, mix evenly at the same speed.

[0041] At a speed of 450r / min, add (NH 4 ) 2 S 2 o 8 Induces polymerization of olefin monomers. After reacting for 25 minutes, cool naturally to obtain a hydrophobic and oleophobic self-cleaning coating.

PUM

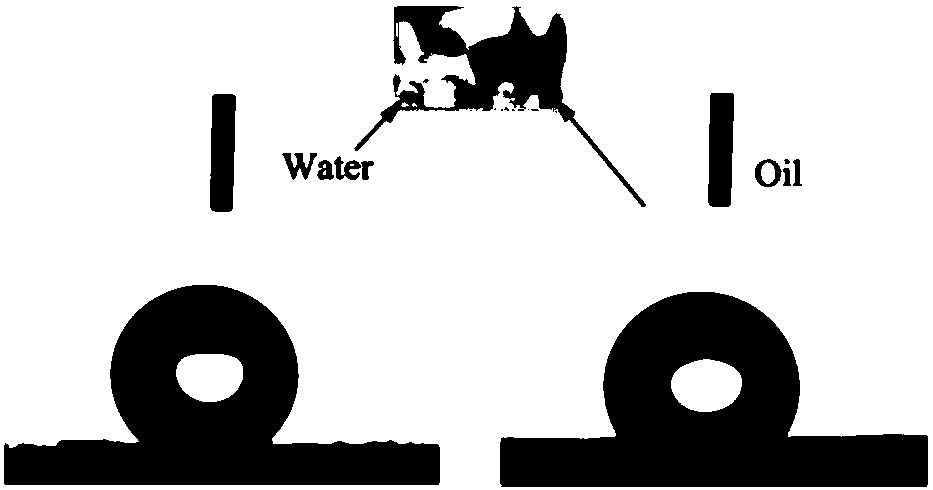

| Property | Measurement | Unit |

|---|---|---|

| Water contact angle | aaaaa | aaaaa |

| Oil contact angle | aaaaa | aaaaa |

| Oil contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com