Flexible wearable mechanical sensor and manufacturing method thereof

A sensor and mechanical technology, applied in the field of flexible wearable mechanical sensors and their preparation, can solve the problems of low sensitivity, single detection position, and low detection range of flexible mechanical sensors, and achieve excellent mechanical sensitivity characteristics, high measurable range, The effect of high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

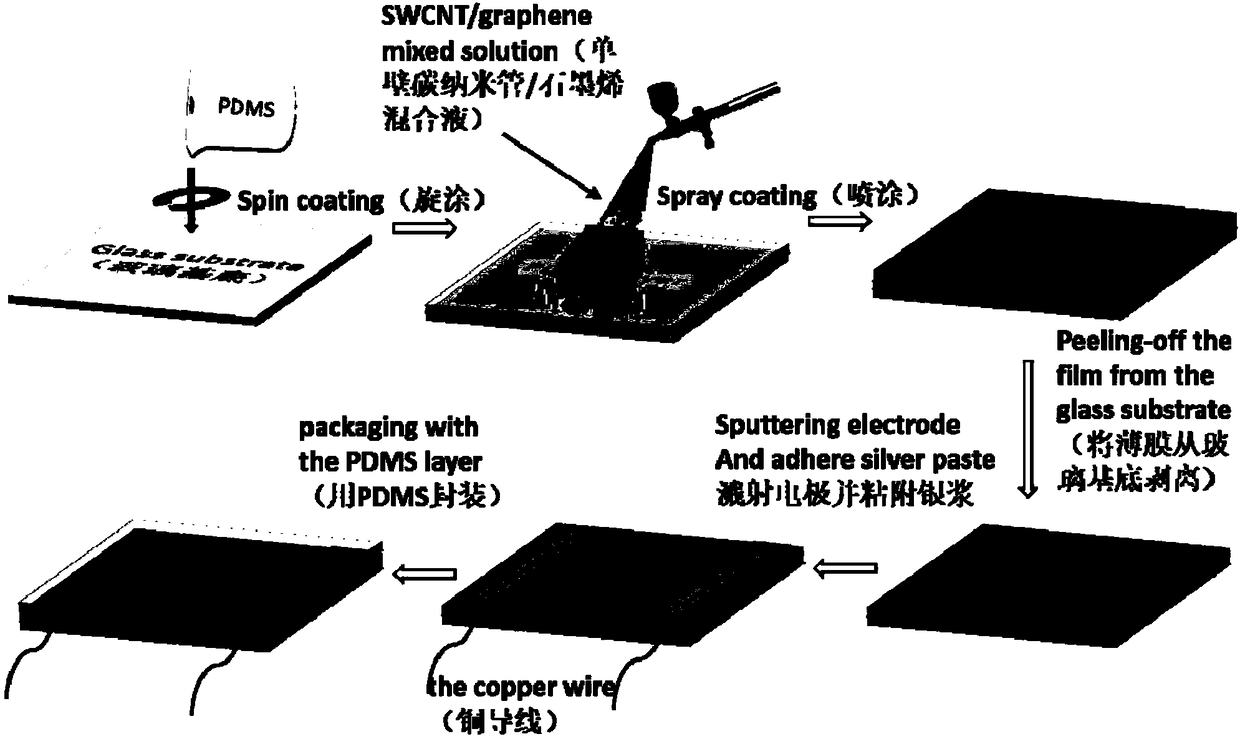

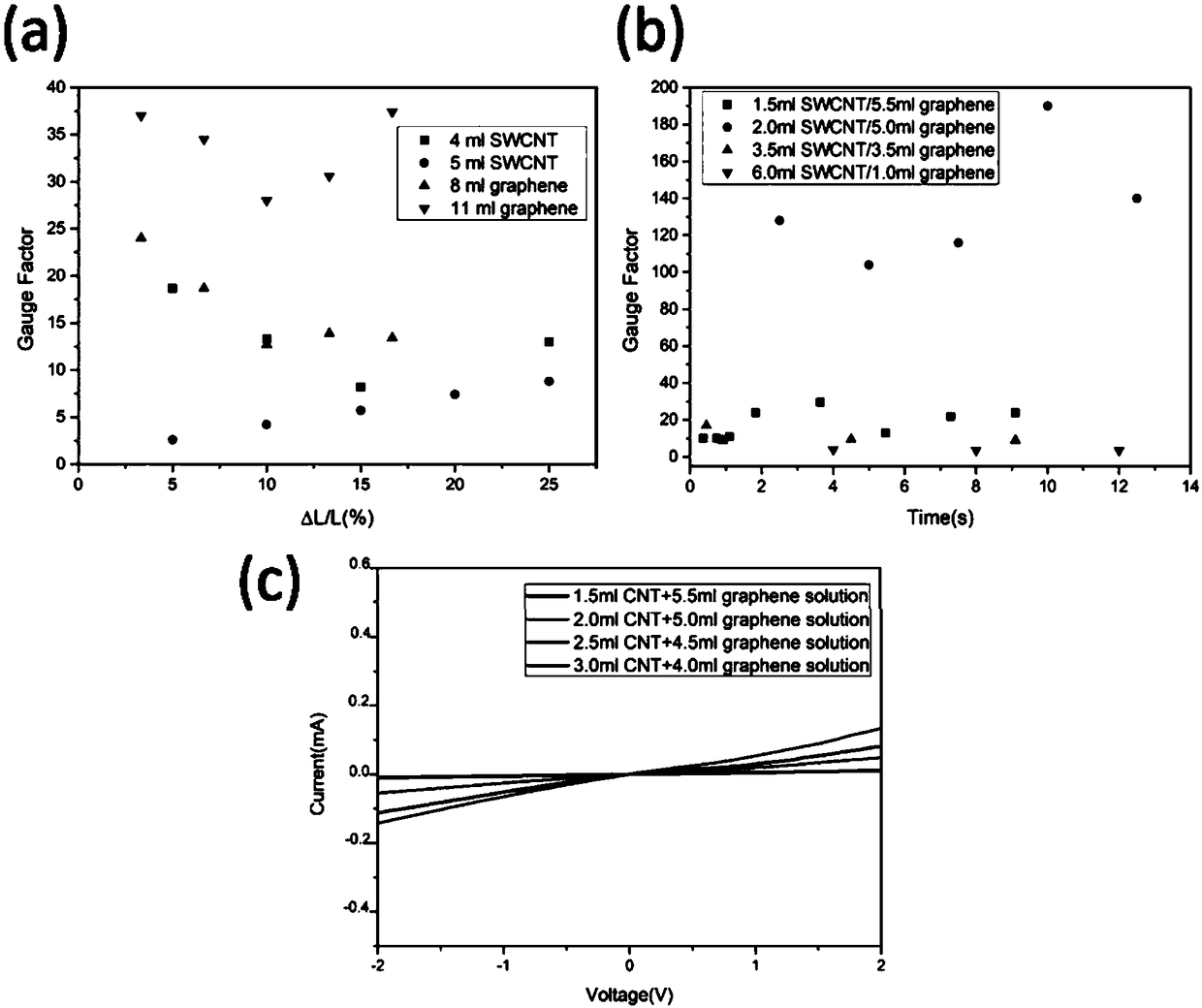

Method used

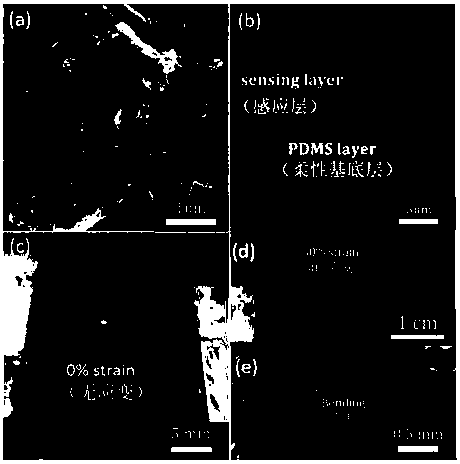

Image

Examples

Embodiment 1

[0023] (1) Preparation of mixed dispersion

[0024] The graphene dispersion is prepared by dispersing natural graphite in N-methylpyrrolidone (NMP), with a mass fraction of deionized water of 0.2; 50 mg of natural graphite is added to 10 ml of solvent, and ultrasonically dispersed using a sonicator. The ultrasonic power was set at 60W in the pulsed operation mode (on for 2s, off for 3s) for 15 hours, followed by standing for 24 hours to allow the deposition of graphite aggregates that were not dispersed by ultrasound.

[0025] The dispersion was then centrifuged at 3000 rpm for 15 minutes. The obtained supernatant is a graphene dispersion. SWCNT dispersions were prepared by sonicating a mixture of 30 mg SWCNT (single-walled carbon nanotubes) and 105 mg TNWDIS (carbon nanotube aqueous dispersant) in 100 g deionized water. The ultrasonic treatment conditions are the same as those for preparing the graphene dispersion except for the ultrasonic treatment time of 2.5 hours. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com