Flexible nanoporous metal/oxide supercapacitor electrode material and preparation method thereof

A supercapacitor and nanoporous technology, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors, can solve problems such as unfavorable practical applications and many steps, and achieve improved electrochemical performance, increased transportability, and preparation methods. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] Embodiment 1: a kind of preparation method of flexible nanoporous metal / oxide supercapacitor electrode material, comprises the following steps:

[0080] (1) Select Al, Ni, Co, Y, Cu elements with a purity greater than 99.9%, according to Al 82 Ni 6 co 3 Y 6 Cu 3 (atomic percent) for proportioning, the alloy elements of the above proportioning are arc-melted in an Ar protective atmosphere.

[0081] (2) Remelt the master alloy in a quartz tube, spray it on a copper roller with a line speed of 40m / s and throw it into an amorphous strip, the thickness of the strip is 20-30μm, the width is 1-2mm, and the length is ten a few meters.

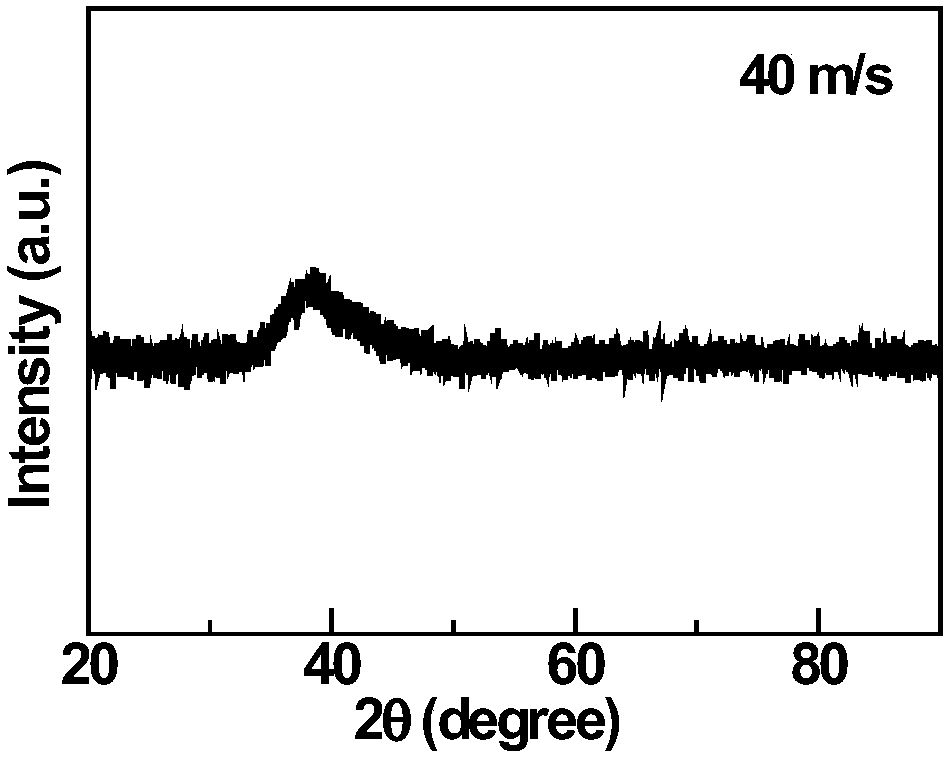

[0082] The amorphous strips are wound into different radii of curvature, indicating that the amorphous alloy has good flexibility; the XRD patterns of the strips are as follows figure 1 As shown, there is only one diffuse scattering peak, indicating that it is completely amorphous; the DSC curve of the strip is as follows figure 2 Shown,...

Embodiment 2

[0094] Embodiment 2: a kind of preparation method of flexible nanoporous metal / oxide supercapacitor electrode material, comprises the following steps:

[0095] Step (1) and (2) are with embodiment 1;

[0096] (3) Put the amorphous strip at 257°C and the degree of vacuum is 5×10- 3 Annealed for 10min under the condition of pa. The XRD pattern of the strip after annealing is as follows image 3 As shown in curve (b) in , various nanocrystalline phases are formed.

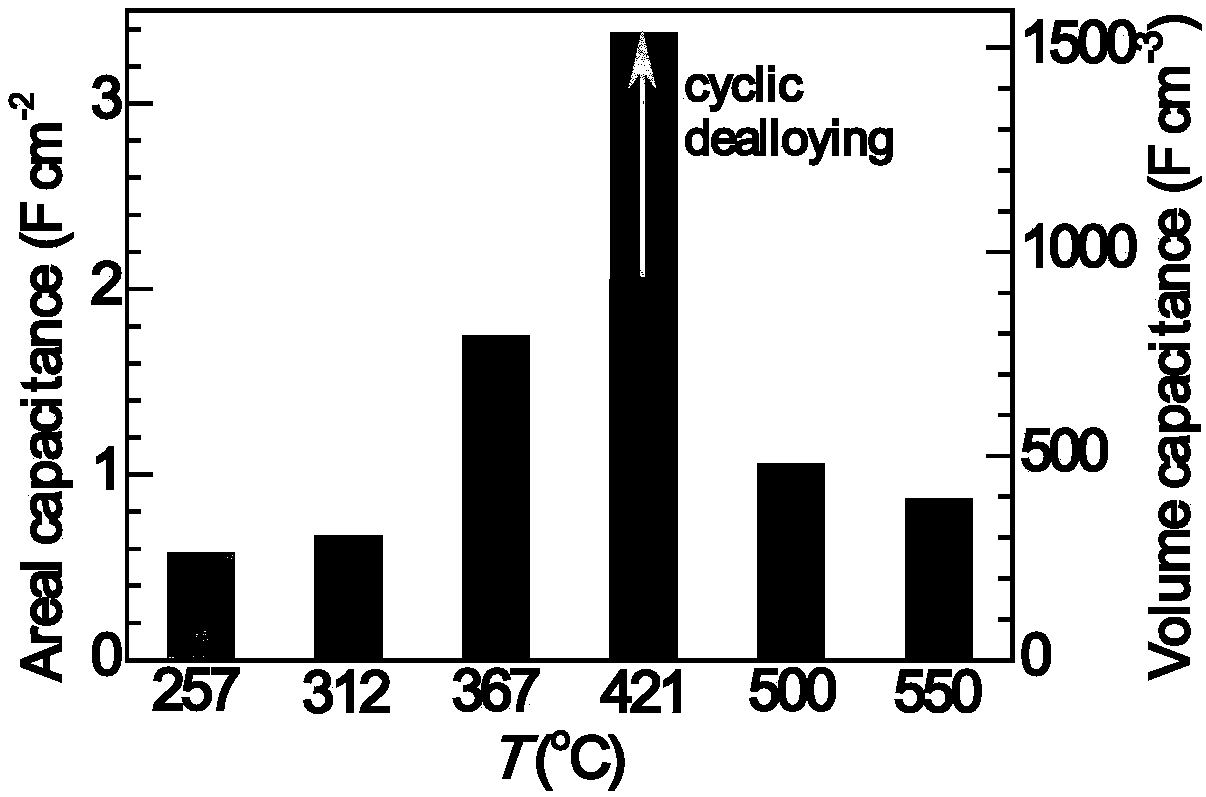

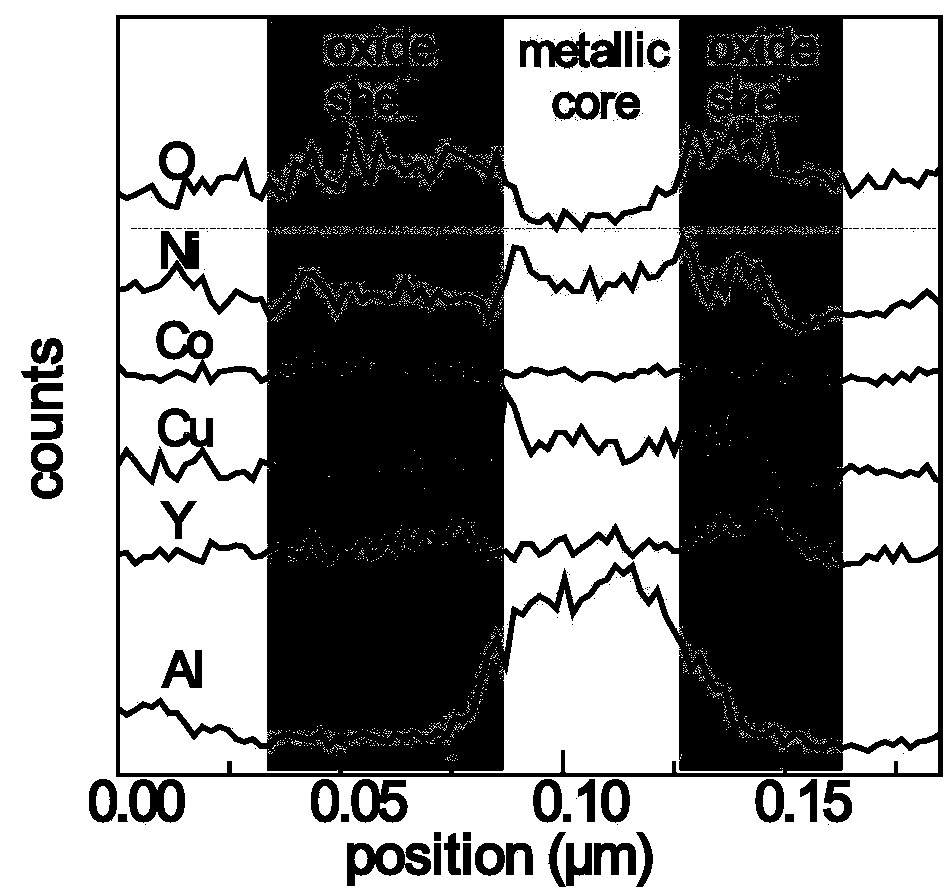

[0097] (4) The strips after annealing were put into 4mol / L KOH solution, dealloyed at room temperature for 10min, and washed repeatedly with deionized water and absolute ethanol to prepare the working electrode. The XRD pattern of the strip after dealloying is as follows Figure 4 As shown in the curve (b), the nanocrystalline phase formed by annealing is dissolved, and (Ni, Co, Cu)O, (Ni, Co)OOH, Y 2 o 3 And trace amounts of Al nanocrystals and Al(OH) 3 Precipitation, these oxides / hydroxides play an important ...

Embodiment 3

[0103] Embodiment 3: a kind of preparation method of flexible nanoporous metal / oxide supercapacitor electrode material, comprises the following steps:

[0104] Step (1) and (2) are with embodiment 1;

[0105] (3) Put the amorphous strip at 312°C with a vacuum of 5×10 -3 Annealed under Pa conditions for 10min. The XRD pattern of the strip after annealing is as follows image 3 As shown in curve (c) in , various nanocrystalline phases are formed.

[0106] (4) The strips after annealing were put into 4mol / L KOH solution, dealloyed at room temperature for 10min, and washed repeatedly with deionized water and absolute ethanol to prepare the working electrode. The XRD pattern of the strip after dealloying is as follows Figure 4 As shown in the curve (c), the nanocrystalline phase formed by annealing is dissolved, and (Ni, Co, Cu) O, (Ni, Co) OOH, Y 2 o 3 And trace amounts of Al nanocrystals and Al(OH) 3 Precipitation, these oxides / hydroxides play an important role in the use...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com