Preparation method of high-capacity high-safety solid-state lithium battery

A solid-state lithium, high-capacity technology, applied in the field of green energy storage, can solve the problems of capacity attenuation, energy density mismatch between volume and gravity, etc., to achieve the effect of reducing internal friction, high yield, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

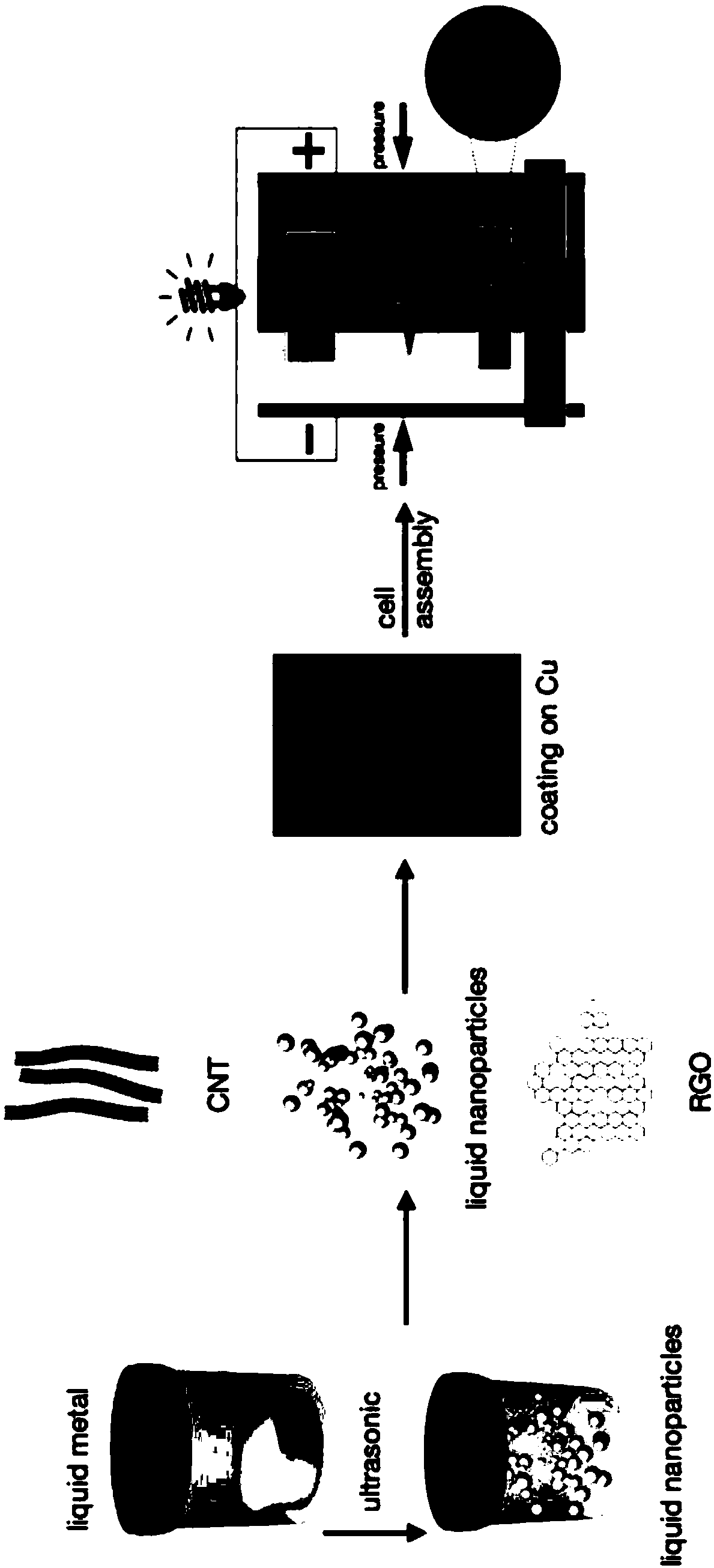

[0029] A method for preparing a high-capacity and high-safety solid-state lithium battery. The liquid metal composite made of liquid metal nanoparticles, carbon nanotubes and graphene is used as the negative electrode active material, and the solid electrolyte is used as the electrolyte. The specific preparation process and the schematic diagram of the solid-state battery structure are as follows: figure 1 shown.

[0030] Further: the preparation method of the liquid metal composite is:

[0031] Step S1: Weigh liquid metal tin and liquid metal gallium according to the mass ratio of 22:3, and add degassed ethanol thiol solvent to it, and then ultrasonically degrade to obtain liquid metal nanoparticles; the degassed ethanol thiol here is Refers to ethanol mercaptan that removes oxygen, generally by passing inert gas such as argon, nitrogen, etc. into the solution to drive away the dissolved oxygen;

[0032] Step S2: adding the liquid metal nanoparticles and carbon nanotubes to...

Embodiment 1

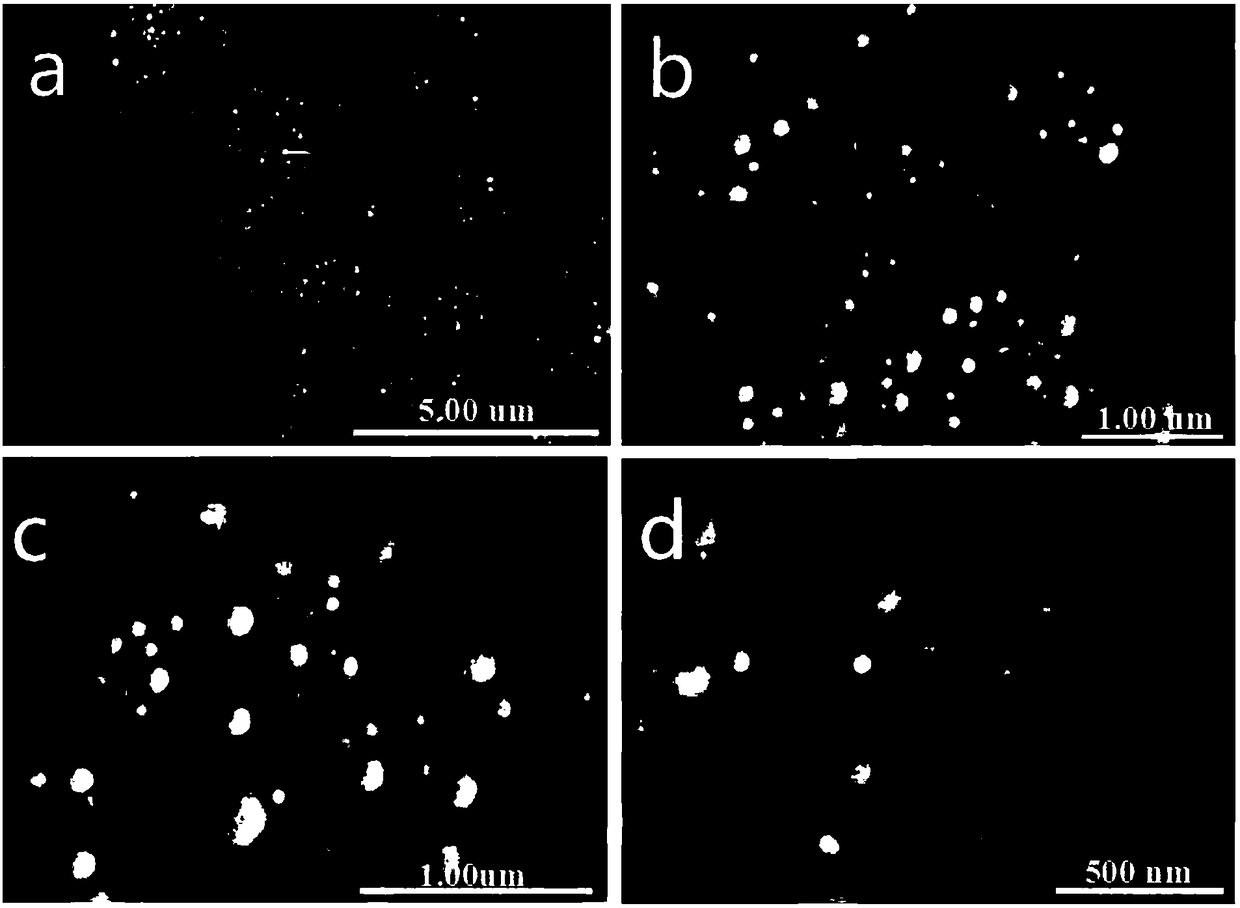

[0040] Example 1. Weigh liquid metal tin and liquid metal gallium in an Eppendorf bottle according to the mass ratio of 22:3, then add 1 mmol / L degassed ethanol mercaptan as a solvent, and then ultrasonicate at 50°C for 1 hour to form liquid metal nanoparticles, such as figure 2 As shown, the prepared liquid metal particles are well dispersed and uniform in particle size, which can meet the requirements of battery active materials;

[0041] 60 mg of the liquid metal nanoparticles and 12 mg of carbon nanotubes were added to 0.5 mL of absolute ethanol to form a mixture I; in order to obtain a more uniform suspension, the mixture I was sonicated for 1 hour; at the same time, in order to obtain a more pure carbon , before using the carbon nanotubes, the carbon nanotubes were refluxed with 2.6mol / L nitric acid; then the mixture I was washed repeatedly with deionized water, and then 4mg of graphene was dissolved in 2wt% ethanol, 2wt% means that the mass percentage is 2%, and it is...

Embodiment 2

[0046] Example 2. Weigh liquid metal tin and liquid metal gallium in an Eppendorf bottle according to the mass ratio of 22:3, then add 1 mmol / L degassed ethanol mercaptan as a solvent, and then ultrasonicate at 50°C for 1 hour to form liquid metal nanoparticles;

[0047] 60 mg of the liquid metal nanoparticles and 12 mg of carbon nanotubes were added to 0.5 mL of absolute ethanol to form a mixture I; in order to obtain a more uniform suspension, the mixture I was sonicated for 1 hour; at the same time, in order to obtain a more pure carbon , before using the carbon nanotubes, the carbon nanotubes were refluxed with 2.6mol / L nitric acid; then the mixture I was washed repeatedly with deionized water, and then 4mg of graphene was dissolved in 2wt% ethanol, And add it into mixture I to form mixture II; ultrasonicate mixture II for 10 minutes, then seal it in a high-temperature reactor and react at a temperature of 160°C for 6h, and then react at a temperature of 900°C for 4h, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com