Production technology of malt powder enriched with selenium and zinc

A zinc-enriched malt powder and production process technology, which can be used in skin care preparations, functions of food ingredients, medical preparations containing active ingredients, etc., can solve problems such as excessive residual inorganic selenium, malt poisoning, and inorganic selenium toxicity. Achieve the effect of enhancing physiological function, strengthening physiological function and increasing selenium function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

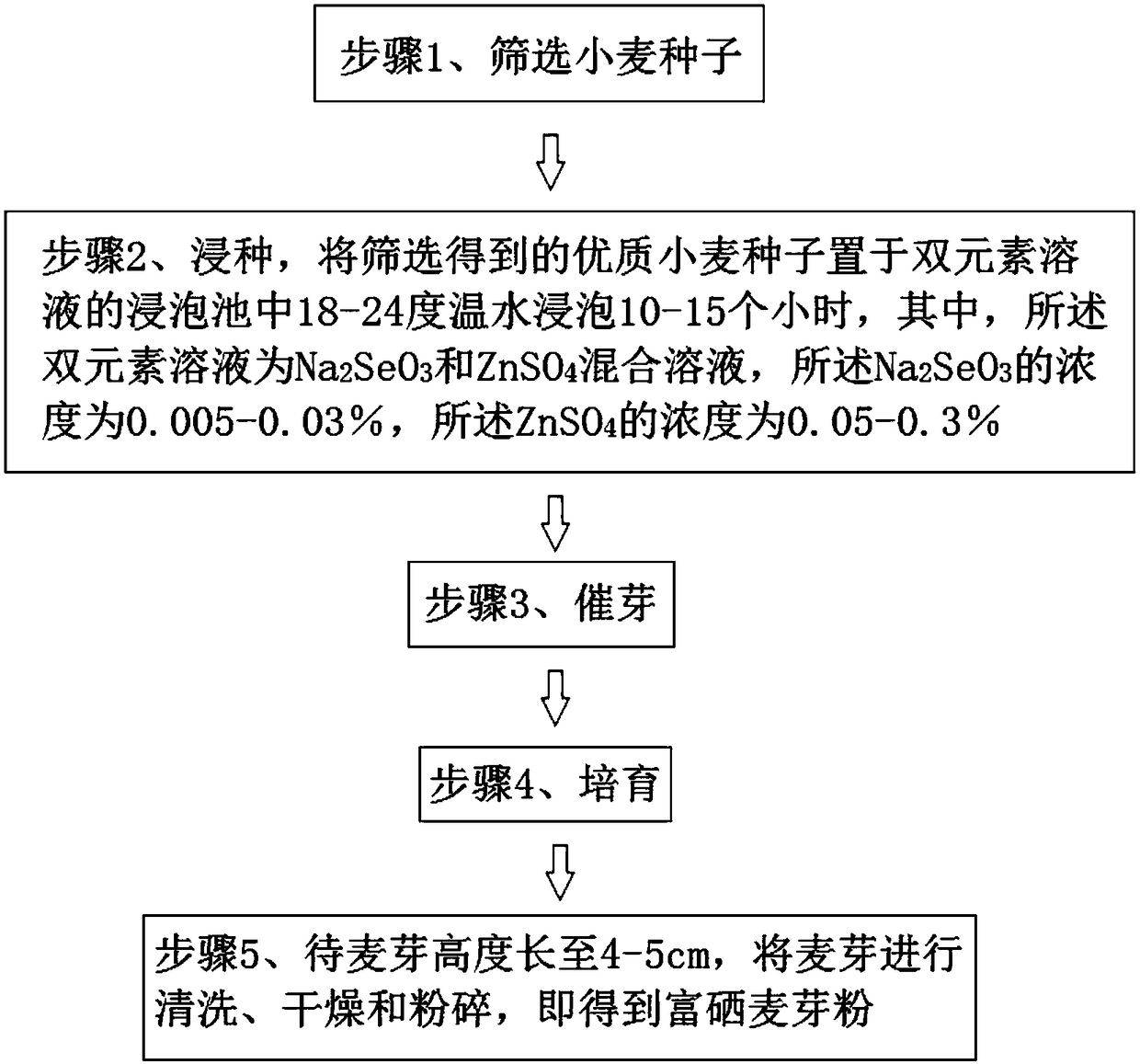

[0017] Step 1. Screen wheat seeds, screen the wheat seeds to remove inferior seeds, and obtain high-quality wheat seeds;

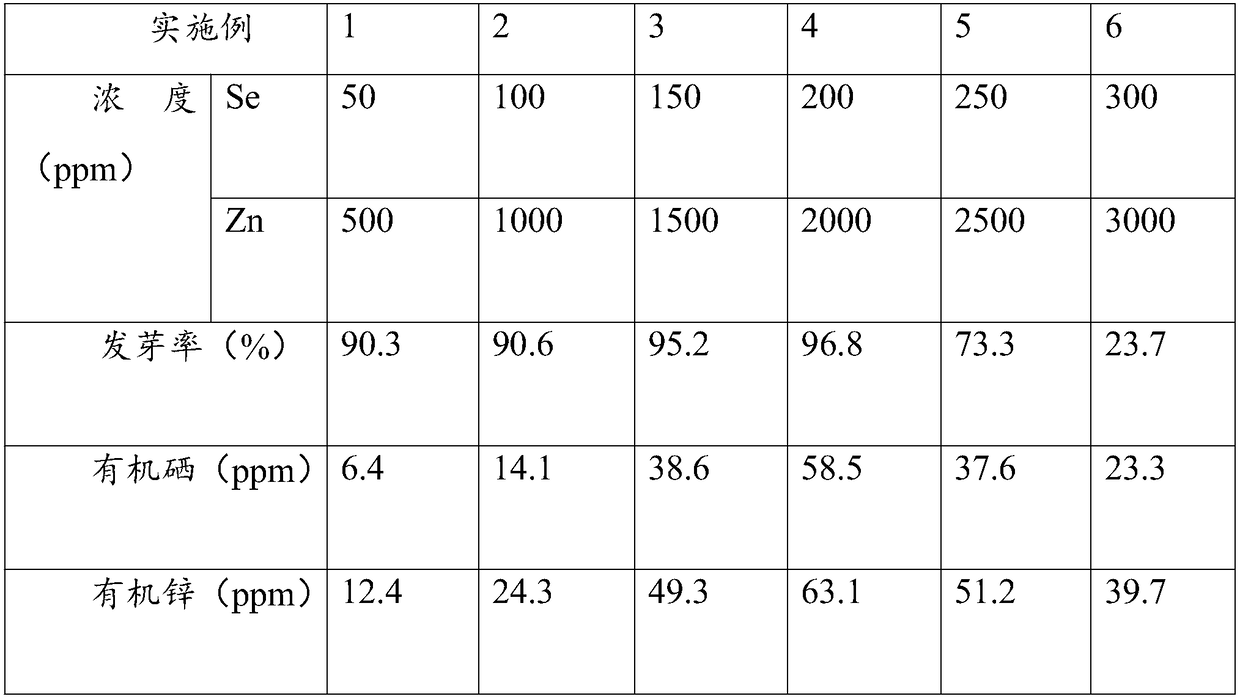

[0018] Step 2. Seed soaking. The high-quality wheat seeds selected in step 1 are soaked in warm water at 22°C in a dual element solution soaking tank for 12 hours, wherein the dual element solution is Na 2 SeO 3 And ZnSO 4 Mixed solution, the Na 2 SeO 3 The concentration of 50ppm, the ZnSO 4 The concentration is 500ppm;

[0019] Among them, the ppm concentration (parts permillion) is the concentration expressed in parts per million of the mass of the solute in the mass of the total solution, also known as the concentration of parts per million. It is often used in very small concentrations.

[0020] Step 3. Accelerate the germination, take the wheat out of the soaking tank and place it in a dish for accelerating germination, the temperature is 15-30℃, and the time is 0.5-3 days;

[0021] Step 4. Cultivation. After the germination is completed, the wheat obtained i...

Embodiment 2

[0025] The methods of step 1 and step 3-6 are the same as in embodiment 1. the difference is:

[0026] Step 2. Seed soaking. The high-quality wheat seeds selected in step 1 are soaked in warm water at 22°C in a dual element solution soaking tank for 12 hours, wherein the dual element solution is Na 2 SeO 3 And ZnSO 4 Mixed solution, the Na 2 SeO 3 The concentration of 100ppm, the ZnSO 4 The concentration is 1000ppm;

Embodiment 3

[0028] The methods of step 1 and step 3-6 are the same as in embodiment 1. the difference is:

[0029] Step 2. Seed soaking. The high-quality wheat seeds selected in step 1 are soaked in warm water at 22°C in a dual element solution soaking tank for 12 hours, wherein the dual element solution is Na 2 SeO 3 And ZnSO 4 Mixed solution, the Na 2 SeO 3 The concentration of 150ppm, the ZnSO 4 The concentration is 1500ppm;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com