Load type arsenic adsorbent, preparation method and application thereof, and arsenic removal method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

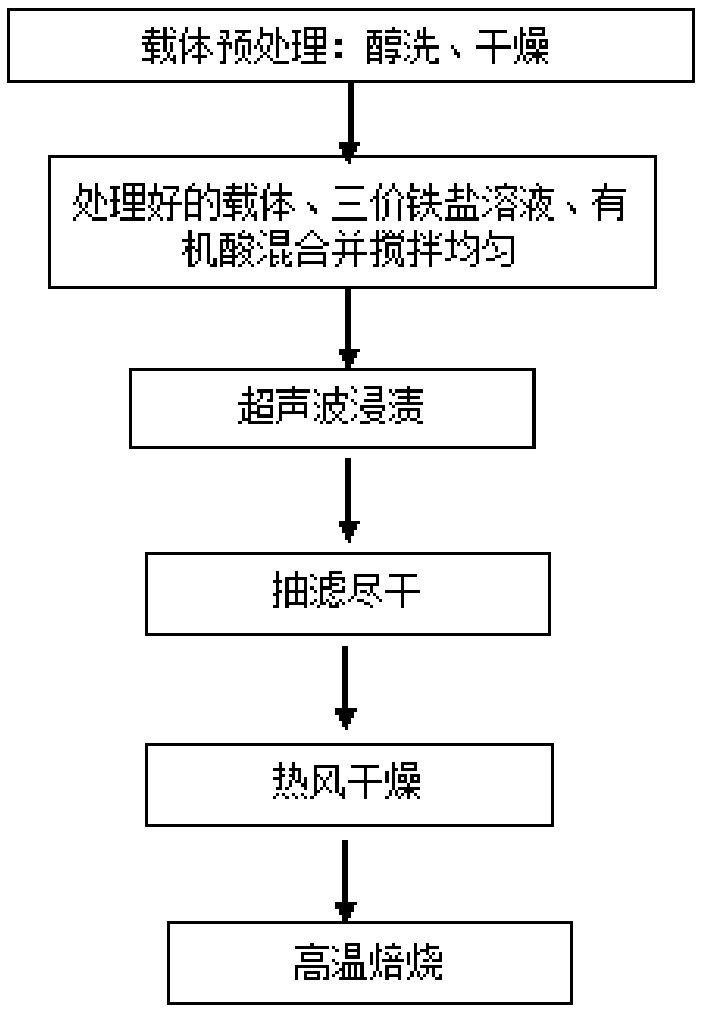

[0027] According to a second aspect of the present invention, a method for preparing a loaded arsenic adsorbent is provided, the method comprising:

[0028] (1) impregnating the alumina carrier in a mixed solution containing ferric salt and an organic acid, the conditions of impregnation are such that the ferric salt is loaded on the alumina carrier to obtain a precursor of a loaded arsenic adsorbent;

[0029] (2) drying and calcining the precursor of the loaded arsenic adsorbent to obtain the loaded arsenic adsorbent.

[0030] According to the present invention, the ferric salt may be various ferric salts conventionally used in the prior art, for example, it may be one or more of ferric chloride, ferric nitrate and ferric sulfate.

[0031] According to the present invention, preferably, the alumina carrier is γ-Al 2 o 3 , when it is combined with the specific iron salt and preparation steps as described above, the prepared adsorbent can achieve more excellent effects.

[0...

Embodiment 1

[0051] This example is used to illustrate the preparation method of the loaded arsenic adsorbent provided by the present invention

[0052] (1) The particle size is 26-32 mesh γ-Al 2 o 3 Place in ethanol solution for shaking, take out 175°C hot air after 30min and dry for 30min, after the temperature drops to room temperature (usually 20-40°C), put γ-Al 2 o 3 Place in ethanol solution for shaking washing. Repeat this step 3 times.

[0053] (2) Prepare 50wt.% ferric nitrate solution, weigh a certain mass of citric acid according to the mass ratio of ferric nitrate and citric acid as 1:0.05, and pour it into the solution. Weigh 30g of γ-Al after step (1) treatment 2 o 3 The carrier was poured into 80 mL of ferric nitrate solution added with citric acid to obtain a mixture.

[0054] (3) Place the mixed solution in step (2) in an ultrasonic oscillator for ultrasonic impregnation, set the water temperature of the ultrasonic oscillator to 50° C., and take it out after 4 hours...

Embodiment 2

[0057] This example is used to illustrate the preparation method of the loaded arsenic adsorbent provided by the present invention

[0058] (1) The particle size is 60-70 mesh γ-Al 2 o 3 Place in ethanol solution for shaking, take out 175°C hot air after 30min and dry for 30min, after the temperature drops to room temperature (usually 20-40°C), put γ-Al 2 o 3 Place in ethanol solution for shaking washing. Repeat this step 3 times.

[0059] (2) Prepare a 10wt.% ferric chloride solution, weigh a certain mass of oxalic acid according to the mass ratio of ferric nitrate and oxalic acid as 1:0.01, and pour it into the solution. Weigh 30g of γ-Al after step (1) treatment 2 o 3 The carrier was poured into 80 mL of ferric chloride solution added with oxalic acid to obtain a mixture.

[0060] (3) Place the mixed solution in step (2) in an ultrasonic oscillator for ultrasonic impregnation, set the water temperature of the ultrasonic oscillator to 60° C., and take it out after 3 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com