Insoluble inorganic salt micro-nano material as well as preparation method and application thereof

A technology of water-soluble inorganic salts and nano-materials, applied in the direction of inorganic chemistry, chemical instruments and methods, gallium/indium/thallium compounds, etc., can solve the problems that nano-scale materials are not easy, and achieve simple preparation methods, easy production, The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

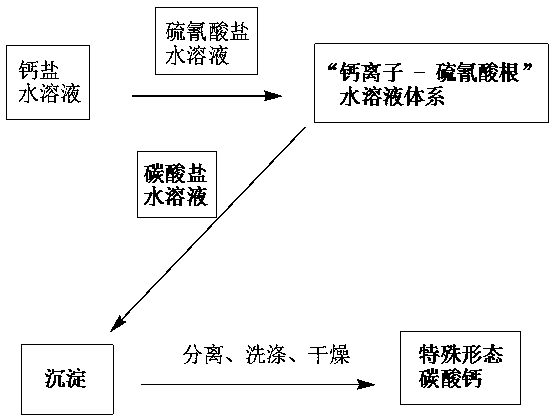

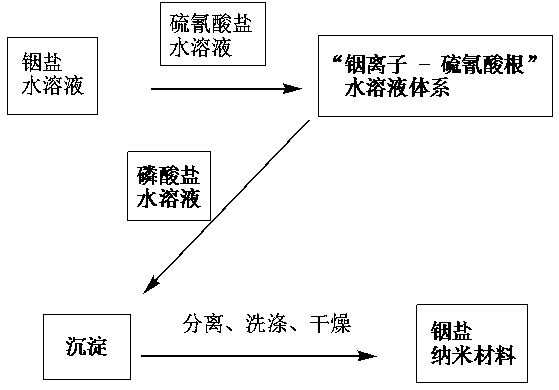

Method used

Image

Examples

Embodiment 1

[0037] 50 mL of 0.1 mol / L CaCl 2 After mixing the aqueous solution and 150 ml of NaSCN aqueous solution with a concentration of 0.1 mol / L in a beaker, add 100 ml of NaSCN with a concentration of 0.1 mol / L 2 CO 3 The aqueous solution is added dropwise into a beaker and left standing for 2 to 4 hours. The product is separated by filtration, washed three times with deionized water, dried in an oven at 60° C., and set aside.

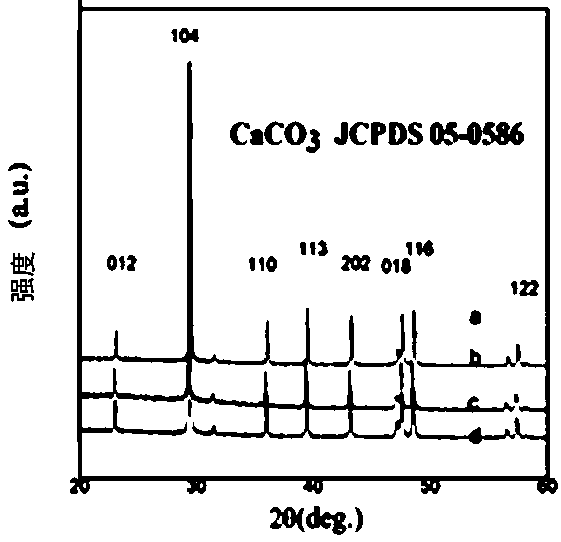

[0038] Powder X-ray diffraction (XRD) analysis confirmed the product to be calcium carbonate. As shown in the curve b in Fig. 3.

[0039] The SEM image shows that the calcium carbonate is a cubic micron-sized particle with a smooth surface, as shown in the b image in Figure 4.

Embodiment 2

[0041] 50 mL of 0.5 mol / L CaCl 2 The aqueous solution and 150 ml of NaSCN aqueous solution with a concentration of 0.5 mol / L were mixed uniformly in a beaker, and then 100 ml of NaSCN with a concentration of 0.5 mol / L 2 CO 3 The aqueous solution is added dropwise into a beaker and left to stand for 2 to 4 hours. The product is separated by filtration, washed three times with deionized water, dried in an oven at 60°C, and set aside.

[0042] Powder X-ray diffraction (XRD) analysis confirmed the product to be calcium carbonate. As shown in the curve c in Fig. 3.

[0043] SEM images show that calcium carbonate is a quasi-cubic micron-sized particle with a rough surface, which is stacked by sheet-like structures, as shown in image c in Figure 4.

Embodiment 3

[0045] 50 mL of 2 mol / L CaCl 2 After mixing the aqueous solution and 150 ml of NaSCN aqueous solution with a concentration of 2 mol / L in a beaker, add 100 ml of NaSCN with a concentration of 2 mol / L 2 CO 3 The aqueous solution is added dropwise into a beaker and left to stand for 2 to 4 hours. The product is separated by filtration, washed three times with deionized water, dried in an oven at 60°C, and set aside.

[0046]Powder X-ray diffraction (XRD) analysis confirmed the product to be calcium carbonate. As shown in the curve d in Fig. 3.

[0047] SEM images show that there are a large number of quasi-spherical and ellipsoidal micro-particles in calcium carbonate, which are stacked by sheet-like nanoscale structures, as shown in the d image in Figure 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com