Ferrite material NiCuZn with large current-resistant property and low-temperature sintering property and preparation method thereof

A ferrite material and low-temperature sintering technology, which is applied in the field of low-temperature sintering NiCuZn ferrite material and its preparation, can solve the problems of the decrease of the effective magnetic permeability of the magnetic core, the increase of the process complexity, and the unsatisfactory effect, and achieves comprehensive Excellent magnetic properties, easy operation and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

[0027] A low-temperature sintered NiCuZn ferrite material with high magnetic field resistance, the main phase is a spinel structure, and its molecular structure expression is Ni 0.27 Zn 0.5 Cu 0.18 co 0.05 Fe 1.95 o 4 . On the basis of the above NiCuZn ferrite material formula, 1wt% Bi is used at the same time 2 o 3 and 2.5wt% Zn 2 SiO 4 Combination doping of calcined materials.

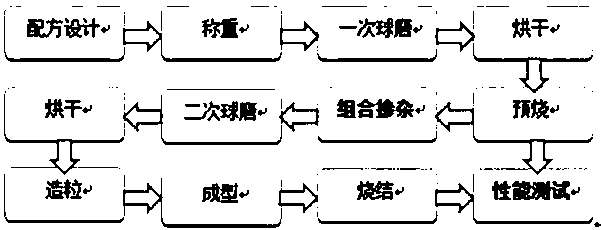

[0028] Its specific preparation method comprises the following steps:

[0029] Step 1, with NiO, ZnO, CuO, Co 2 o 3 , Fe 2 o 3 As the initial raw material, in molar ratio NiO:ZnO:CuO:Fe 2 o 3 =0.27:0.5: 0.18 : 0.025:0.975 to convert NiO, ZnO, CuO, Co 2 o 3 , Fe 2 o 3 The mass ratio is weighed, mixed, and dried after a ball mill;

[0030] Step 2. Sieve the primary ball mill drying material obtained in step 1, compact and punch holes in the crucible, ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com