Pantograph carbon slide plate made of carbon-carbon composite material and preparation method thereof

A pantograph carbon sliding plate and carbon composite material technology, applied in the field of carbon sliding plate, can solve the problems of not fully satisfying the physical and chemical indicators of the carbon sliding plate, poor impact resistance, easy to break or rupture, etc., and achieve high friction and wear resistance. Good electrical conductivity, the effect of improving bulk density and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

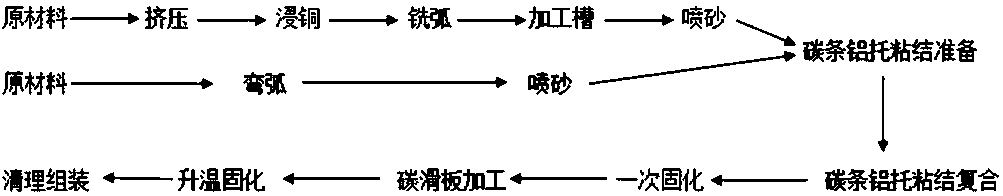

Method used

Image

Examples

Embodiment Construction

[0047] Below in conjunction with embodiment the present invention is further described.

[0048] Through a detailed exploration of raw materials, formulas, and preparation processes, a carbon-carbon composite pantograph carbon slide with a volume density of ≤2.8g / cm 3 , flexural strength ≥ 70Mpa, compressive strength ≥ 100Mpa, impact toughness ≥ 0.20J / cm 2, Rockwell hardness (HR5 / 150) ≤ 50. The index is better than TB / T 1842.2-2016 "Pantograph Skateboard Part 2: Carbon-Based Composite Skateboard". Due to the addition of carbon-carbon composite materials, this technology significantly improves the electrical conductivity and thermal conductivity of the pantograph carbon slideboard material And friction, wear.

[0049] A carbon-carbon composite material pantograph carbon slide plate is made of carbon-carbon composite material, semi-reinforcing carbon black, pitch coke, and graphite powder as aggregates, and medium-temperature reformed coal tar pitch as a binder.

[0050] The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com