Method for modifying surface of ITO electrode

A technology of electrode surface and indium tin oxide, which is applied in circuits, electrical components, electric solid devices, etc., can solve the problems of uneconomical and high cost, and achieve the effects of saving materials, high power efficiency, and improving current efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

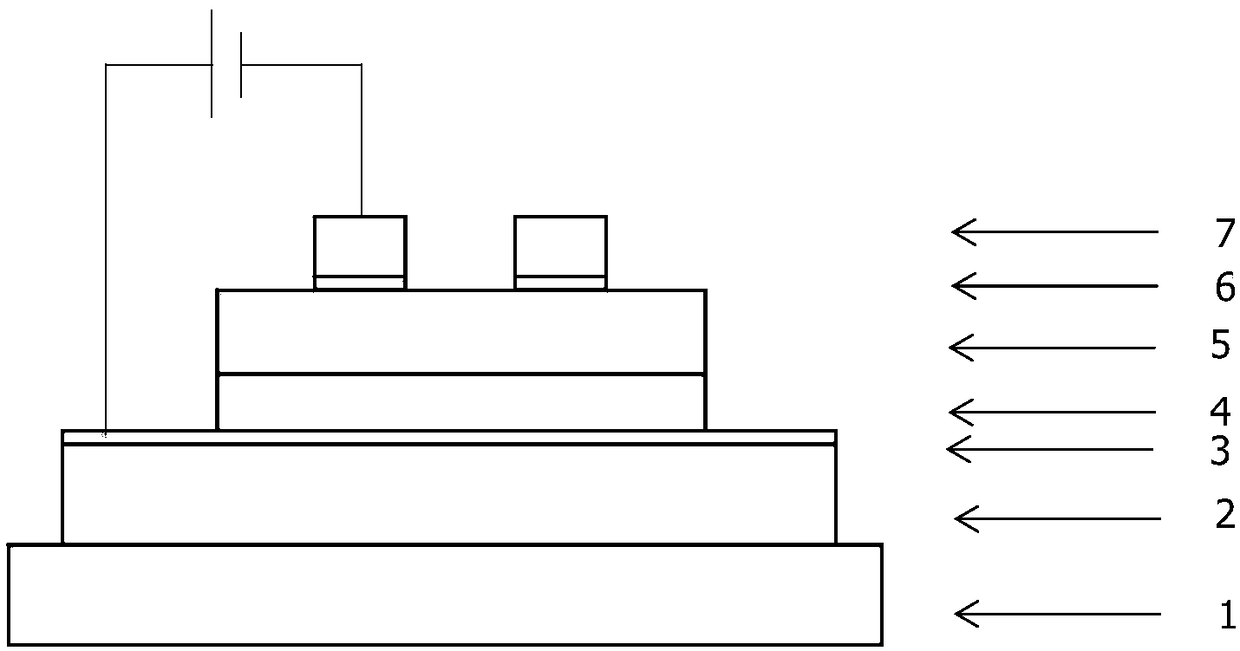

[0033] Embodiment 1: The thickness of the anode interface layer pentacene is selected to be 0.5nm, and the device structure is glass / ITO / pentacene (0.5nm) / NPB (50nm) / Alq 3 (60nm) / LiF(1nm) / Al(150nm).

[0034] When the bottom electrode uses ITO glass as the substrate, the ITO is first photoetched into a strip electrode with a width of 3 mm and a length of 30 mm, and then ultrasonically cleaned with acetone, isopropanol, cleaning agent, and deionized water, and blown with nitrogen. Drying, using a fixed flow of oxygen plasma treatment for 4 minutes; then on the ITO glass substrate, the anode interface layer pentacene (pentacene), the hole transport layer (NPB), the light emitting layer and the electron transport layer (Alq 3 ) cathode interface layer (LiF) and cathode metal (Al), the entire evaporation process is in high vacuum (~10 -4 Pa) environment, and the organic chamber and the metal chamber are operated in the same vacuum environment. Among them, the evaporation rate of ...

Embodiment 2

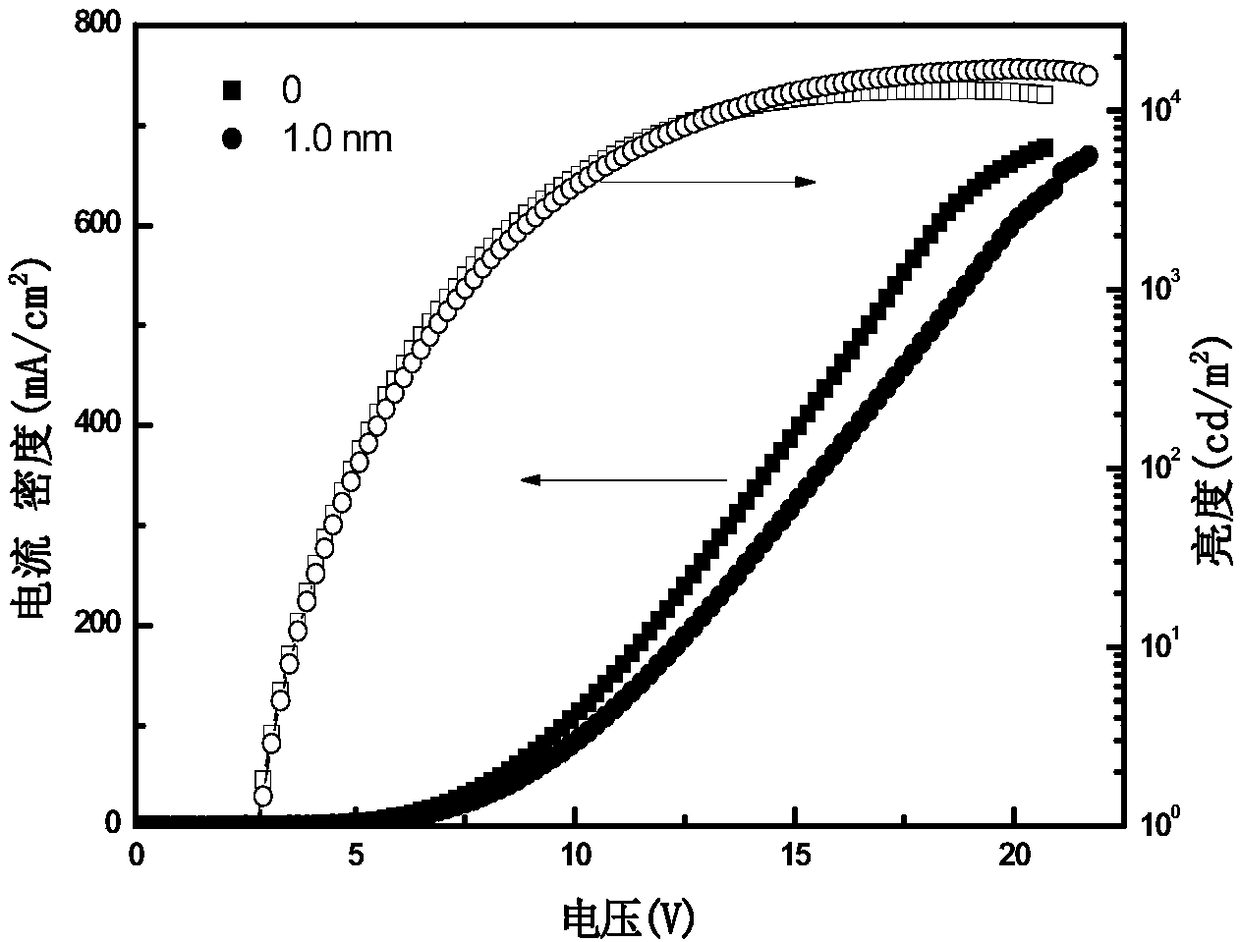

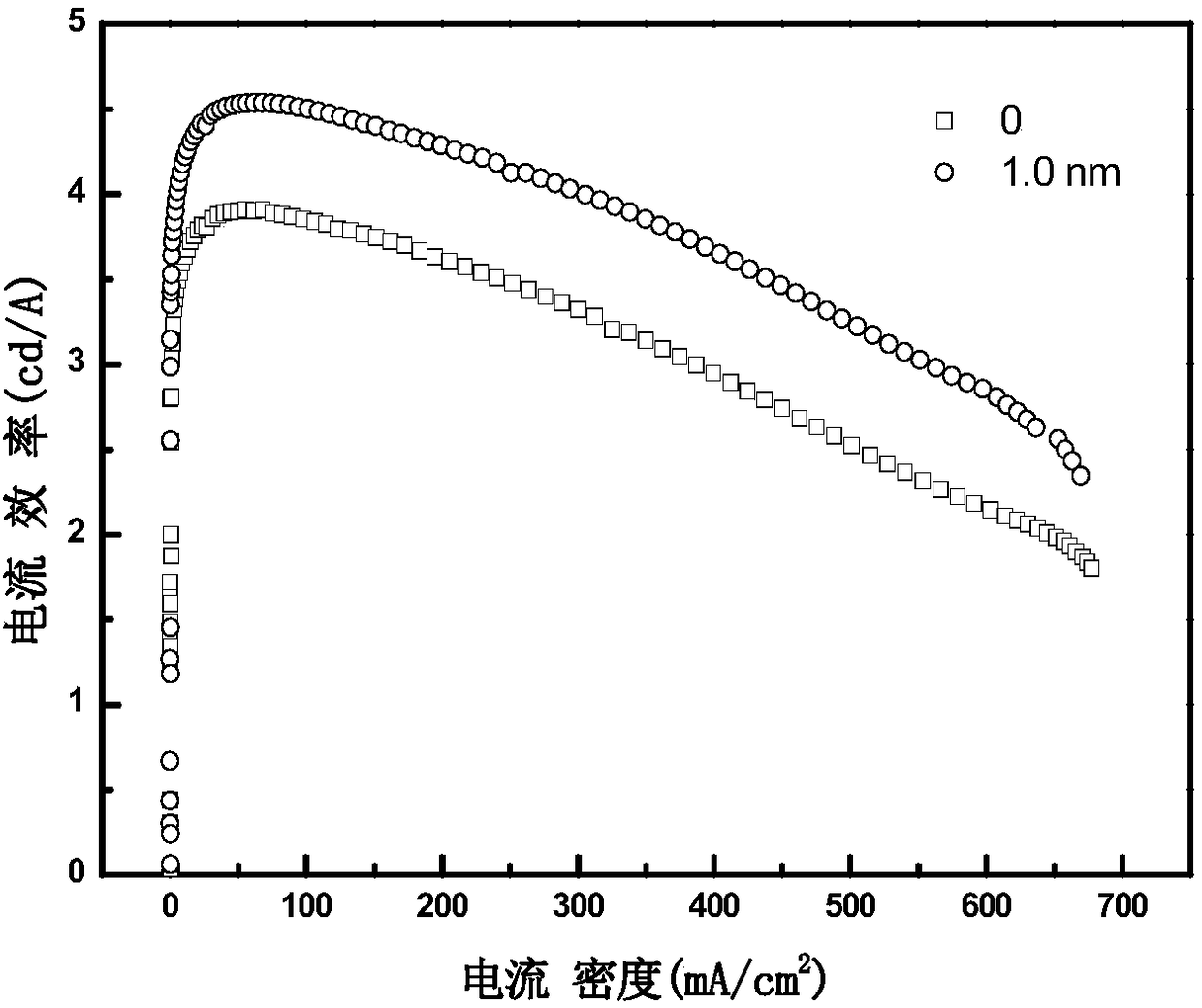

[0035] Example 2: The thickness of the anode interface layer pentacene is selected to be 1.0nm, and the device structure is glass / ITO / pentacene (1.0nm) / NPB (50nm) / Alq 3 (60nm) / LiF(1nm) / Al(150nm).

[0036] When the bottom electrode uses ITO glass as the substrate, the ITO is first photoetched into a strip electrode with a width of 3 mm and a length of 30 mm, and then ultrasonically cleaned with acetone, isopropanol, cleaning agent, and deionized water, and blown with nitrogen. Drying, using a fixed flow of oxygen plasma treatment for 4 minutes; then on the ITO glass substrate, the anode interface layer pentacene (pentacene), the hole transport layer (NPB), the light emitting layer and the electron transport layer (Alq 3 ) cathode interface layer (LiF) and cathode metal (Al), the entire evaporation process is in high vacuum (~10 -4 Pa) environment, and the organic chamber and the metal chamber are operated in the same vacuum environment. Among them, the evaporation rate of pen...

Embodiment 3

[0037] Embodiment 3: The thickness of the anode interface layer pentacene is selected to be 1.5nm, and the device structure is glass / ITO / pentacene (1.5nm) / NPB (50nm) / Alq 3 (60nm) / LiF(1nm) / Al(150nm).

[0038] When the bottom electrode uses ITO glass as the substrate, the ITO is first photoetched into a strip electrode with a width of 3 mm and a length of 30 mm, and then ultrasonically cleaned with acetone, isopropanol, cleaning agent, and deionized water, and blown with nitrogen. Drying, using a fixed flow of oxygen plasma treatment for 4 minutes; then on the ITO glass substrate, the anode interface layer pentacene (pentacene), the hole transport layer (NPB), the light emitting layer and the electron transport layer (Alq 3 ) cathode interface layer (LiF) and cathode metal (Al), the entire evaporation process is in high vacuum (~10 -4 Pa) environment, and the organic chamber and the metal chamber are operated in the same vacuum environment. Among them, the evaporation rate of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com