Current collector containing PTC coatings, and lithium ion battery containing current collector

A current collector and coating technology, applied in batteries, battery electrodes, secondary batteries, etc., can solve the problems of limited improvement effect, inability to block heat-producing side reactions, and inability to be widely used, and achieve normal temperature performance without affecting and reducing Current, the effect of improving needle stick resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

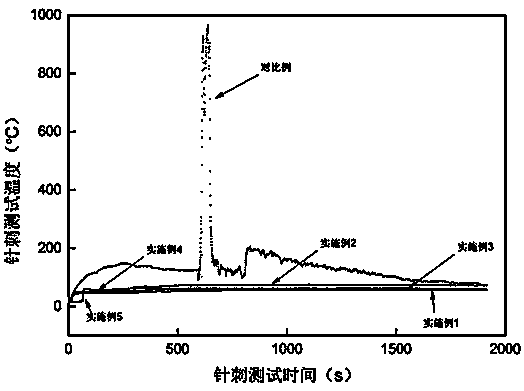

Examples

Embodiment 1

[0030] A current collector containing a PTC coating, including a current collector, the front and back of the current collector are provided with a PTC coating, the thickness of the PTC coating is 1 μm, and the PTC coating is coated on the current collector by PTC slurry and dried After making; the viscosity of PTC slurry is 100mPa s, and it is made by the raw material of following parts by weight: 1 part of polymer powder, 1 part of conductive agent, 1 part of inorganic micropowder, 30 parts of solvent; The polymer powder is Polyethylene and polymer powder are baked at 80°C before pulping; the conductive agent is carbon black; the inorganic micropowder is barium titanate; the solvent is chloroform.

[0031] A lithium ion battery, the current collector of the positive electrode sheet or / and negative electrode sheet adopts the above-mentioned current collector containing PTC coating.

Embodiment 2

[0033] A current collector containing a PTC coating, including a current collector, the front and back of the current collector are provided with a PTC coating, the thickness of the PTC coating is 3 μm, and the PTC coating is coated on the current collector by PTC slurry and dried After making; the viscosity of PTC slurry is 1000mPa s, and it is made by the raw material of following parts by weight: polymer powder 1 part, conductive agent 5 parts, inorganic micropowder 2 parts, solvent 300 parts; Macromolecule powder is Polyvinyl chloride, polymer powder is baked at 90°C before pulping; the conductive agent is vapor-deposited carbon fiber; the inorganic powder is strontium-doped barium titanate BaTi 0.95 Sr 0.05 o 3 ; The solvent is chloroform.

[0034] A lithium ion battery, the current collector of the positive electrode sheet or / and negative electrode sheet adopts the above-mentioned current collector containing PTC coating.

Embodiment 3

[0036] A current collector containing a PTC coating, including a current collector, the front and back of the current collector are provided with a PTC coating, the thickness of the PTC coating is 5 μm, and the PTC coating is coated on the current collector by PTC slurry and dried After making; the viscosity of PTC slurry is 1500mPa·s, and it is made by the raw material of following parts by weight: 1 part of polymer powder, 10 parts of conductive agent, 10 parts of inorganic micropowder, 500 parts of solvent; Polypropylene, polyvinylidene fluoride and polymethyl methacrylate are mixed in a weight ratio of 1:1.2:0.9, and the polymer powder is baked at 110°C before pulping; the conductive agent is carbon nanotubes and titanium monoxide Weight ratio 1:1.2 composition; inorganic powder is niobium doped barium titanate BaTi 0.9 Nb 0.1 o 3; The solvent is N-methylpyrrolidone.

[0037] A lithium ion battery, the current collector of the positive electrode sheet or / and negative el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com