A high temperature oxidation resistant w-cr-ti composite material

A technology of anti-high temperature oxidation and composite materials, which is applied in the field of metal composite materials and its preparation, to achieve the effects of improving stability, improving bonding ability, and reducing cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

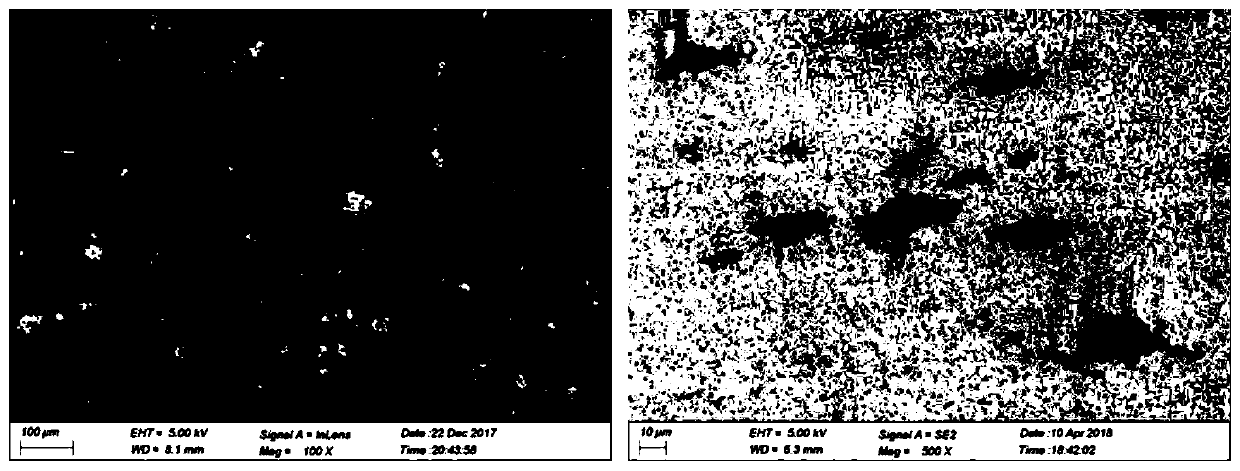

Image

Examples

Embodiment 1

[0025] In this embodiment, the high-temperature oxidation-resistant W-Cr-Ti composite material, its doping raw materials are W-12Cr alloy powder and W-5Ti alloy powder, wherein each component is constituted by mole percentage: W-12Cr 90%, W- 5Ti 10%.

[0026] The primary powder particle size is: W-12Cr alloy powder particle size is 5.2 microns, W-5Ti alloy powder particle size is 4 microns.

[0027] The preparation method of the high temperature oxidation resistant W-Cr-Ti composite material in this embodiment comprises the following steps:

[0028] 1. Powder making: Mix W-12Cr alloy powder and W-5Ti alloy powder according to the ratio, and stir in a powder mixer at 400 rpm for 2 hours to obtain W-Cr-Ti dual-phase composite powder;

[0029] 2. Sintering: Put the W-Cr-Ti dual-phase composite powder into the graphite mold, then put the mold into the discharge plasma sintering furnace, evacuate the sintering furnace at room temperature, raise the temperature to 1500 ° C for 3 mi...

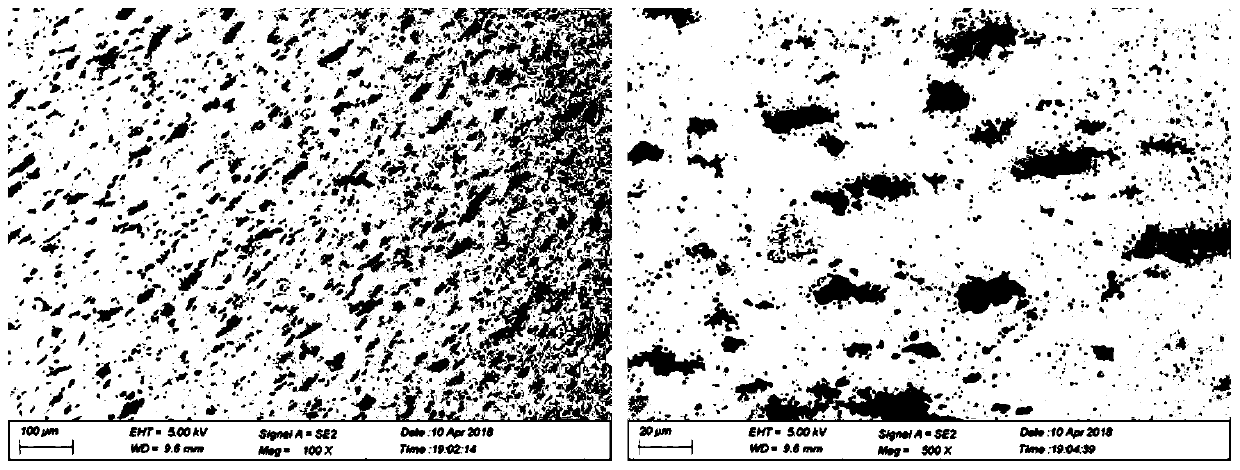

Embodiment 2

[0033] In the high temperature oxidation resistant W-Cr-Ti composite material in this example, its doping raw materials are W-12Cr alloy powder and W-5Ti alloy powder, wherein each component is constituted by mole percentage: W-12Cr 80%, W- 5Ti 20%.

[0034] The primary powder particle size is: W-12Cr alloy powder particle size is 5.2 microns, W-5Ti alloy powder particle size is 4 microns.

[0035] The preparation method of the high temperature oxidation resistant W-Cr-Ti composite material in this embodiment comprises the following steps:

[0036] 1. Powder making: Mix W-12Cr alloy powder and W-5Ti alloy powder according to the ratio, and stir in a powder mixer at 400 rpm for 2 hours to obtain W-Cr-Ti dual-phase composite powder;

[0037] 2. Sintering: Put the W-Cr-Ti dual-phase composite powder into the graphite mold, then put the mold into the discharge plasma sintering furnace, evacuate the sintering furnace at room temperature, raise the temperature to 1500 ° C for 3 min...

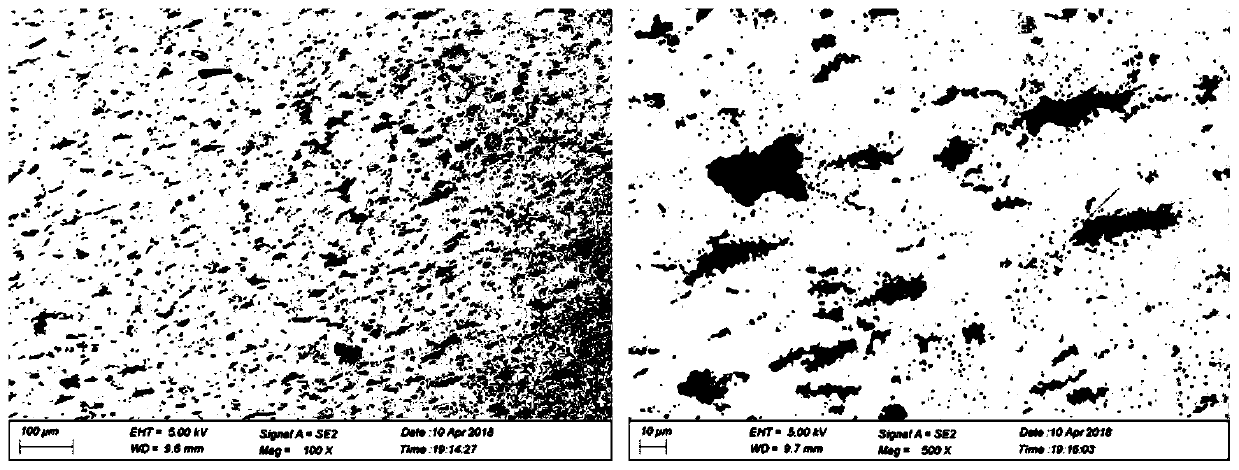

Embodiment 3

[0041] In this embodiment, the high-temperature oxidation-resistant W-Cr-Ti composite material, its doping raw materials are W-12Cr alloy powder and W-5Ti alloy powder, wherein each component is constituted by mole percentage: W-12Cr 70%, W- 5Ti 30%.

[0042] The primary powder particle size is: W-12Cr alloy powder particle size is 5.2 microns, W-5Ti alloy powder particle size is 4 microns.

[0043] The preparation method of the high temperature oxidation resistant W-Cr-Ti composite material in this embodiment comprises the following steps:

[0044]1. Powder making: Mix W-12Cr alloy powder and W-5Ti alloy powder according to the ratio, and stir in a powder mixer at 400 rpm for 2 hours to obtain W-Cr-Ti dual-phase composite powder;

[0045] 2. Sintering: Put the W-Cr-Ti dual-phase composite powder into the graphite mold, then put the mold into the discharge plasma sintering furnace, evacuate the sintering furnace at room temperature, raise the temperature to 1500 ° C for 3 min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com